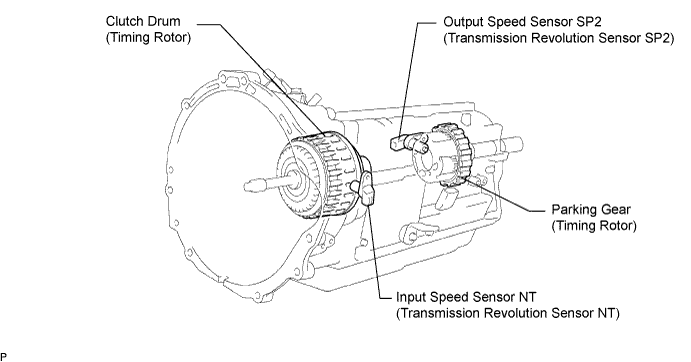

DTC P0717 Input Speed Sensor Circuit No Signal |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0717 |

|

|

| Item | Measurement Item/ Range (Display) | Normal Condition | Diagnostic Note |

| SPD (NT) | Input turbine speed/ display: 50 r/min |

| - |

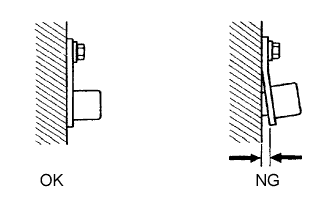

| 1.INSPECT SPEED SENSOR INSTALLATION |

|

Check the speed sensor (NT) installation.

|

| ||||

| OK | |

| 2.INSPECT INPUT SPEED SENSOR (NT) |

|

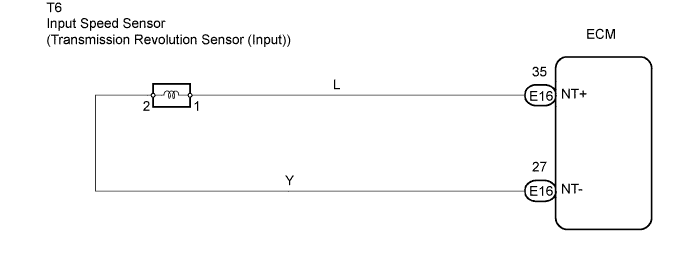

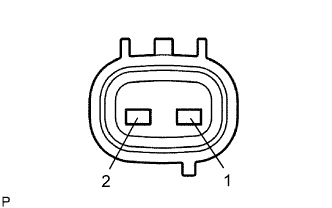

Disconnect the T6 sensor connector from the transmission.

Measure the resistance of the sensor.

| Tester Connection | Condition | Specified Condition |

| 1 - 2 | 20°C (68°F) | 560 to 680 Ω |

|

| Item | Content |

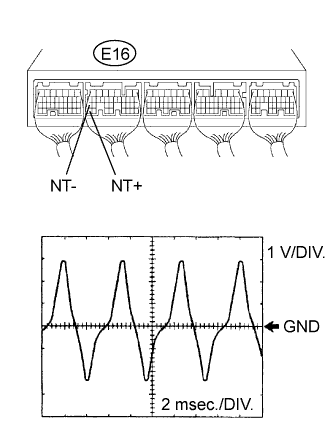

| Tester Connection | E16-35 (NT+) - E16-27 (NT-) |

| Tool Setting | 1 V/DIV., 2 msec./DIV. |

| Condition | Engine idle speed (shift lever on P or N) |

|

| ||||

| OK | |

| 3.CHECK WIRE HARNESS (INPUT SPEED SENSOR - ECM) |

|

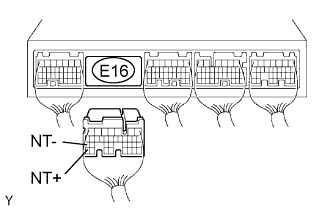

Disconnect the E16 ECM connector.

Measure the resistance of the wire harness side connector.

| Tester Connection | Condition | Specified Condition |

| E16-35 (NT+) - E16-27 (NT-) | 20°C (68°F) | 560 to 680 Ω |

| E16-35 (NT+) - Body ground | 20°C (68°F) | 10 kΩ or higher |

| E16-27 (NT-) - Body ground | 20°C (68°F) | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||