OVERDRIVE DIRECT CLUTCH > INSPECTION |

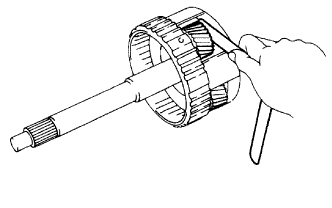

| 1. INSPECT OVERDRIVE ONE-WAY CLUTCH |

|

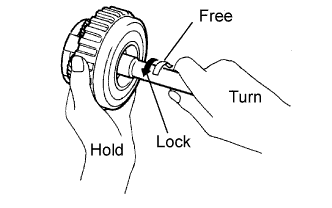

Hold the overdrive direct clutch drum, and turn the input shaft.

Check that the input shaft can be turned freely clockwise and locks when turned counterclockwise.

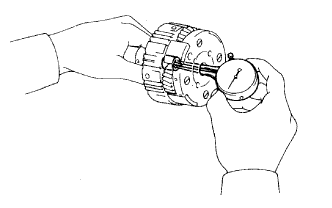

| 2. INSPECT OVERDRIVE DIRECT CLUTCH DRUM |

|

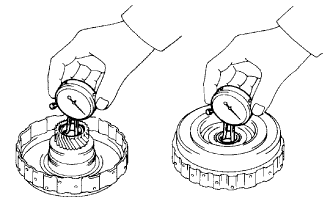

Using a dial indicator, measure the inside diameter of the clutch drum bushes.

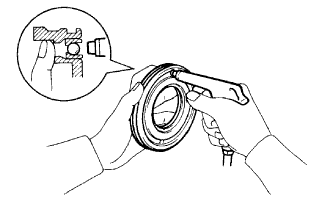

| 3. INSPECT PISTON STROKE OF OVERDRIVE DIRECT CLUTCH |

|

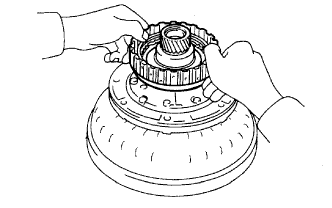

Place the oil pump onto the torque converter clutch, and then place the overdrive direct clutch drum assembly onto the oil pump.

|

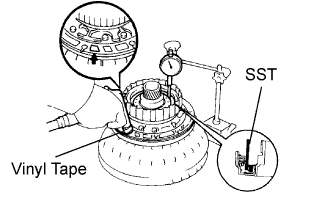

Using SST and a dial indicator, measure the overdrive direct clutch piston stroke while applying and releasing compressed air (392 kPa (4.0 kgf/cm2, 57 psi)).

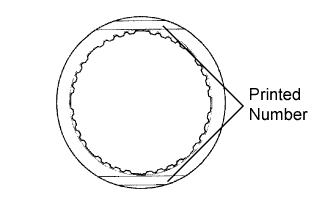

| 4. INSPECT OVERDRIVE DIRECT CLUTCH DISC |

|

Replace all discs if one of the following problems is present: 1) a disc, plate or flange is worn or burnt, 2) the lining of a disc is peeled off or discolored, or 3) grooves or printed numbers have even a little bit of damage.

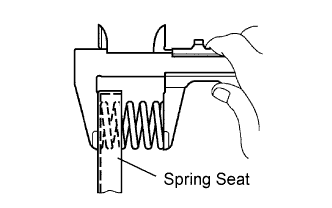

| 5. INSPECT OVERDRIVE DIRECT CLUTCH RETURN SPRING |

|

Using a vernier caliper, measure the free length of the spring together with the spring seat.

| 6. INSPECT OVERDRIVE DIRECT CLUTCH PISTON |

|

Check that the check ball is free by shaking the piston.

Check that the valve does not have leaks by applying low-pressure compressed air.

| 7. INSPECT OVERDRIVE PLANETARY GEAR |

|

Using a dial indicator, measure the inside diameter of the planetary gear bush.

|

Using a feeler gauge, measure the planetary pinion gear thrust clearance.