ENGINE UNIT > REPAIR |

| 1. REPAIR INTAKE VALVE SEAT |

|

Apply a light coat of Prussian blue (or white lead) to the valve face.

Lightly press the valve face against the valve seat.

Check the valve seat according to the following procedure.

If blue appears 360° around the valve face, the valve face is concentric. If not, replace the valve.

If blue appears 360° around the valve seat, the guide and valve face are concentric. If not, resurface the valve seat.

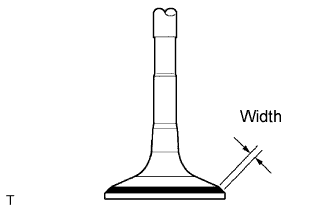

Check that the valve seat contact is in the middle of the valve face with the width between 1.0 to 1.4 mm (0.039 to 0.055 in.).

|

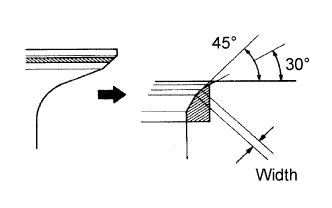

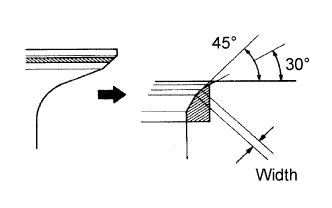

If the seating is too high on the valve face, use 30° and 45° cutters to correct the seat.

|

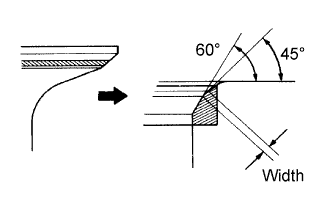

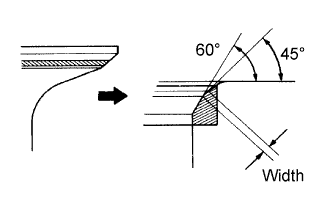

If the seating is too low on the valve face, use 60° and 45° cutters to correct the seat.

Hand rub the valve and valve seat with an abrasive compound.

Check the valve seating position.

| 2. REPAIR EXHAUST VALVE SEAT |

|

Apply a light coat of Prussian blue (or white lead) to the valve face.

Lightly press the valve face against the valve seat.

Check the valve seat according to the following procedures.

If blue appears 360° around the valve face, the valve face is concentric. If not, replace the valve.

If blue appears 360° around the valve seat, the guide and valve face are concentric. If not, resurface the valve seat.

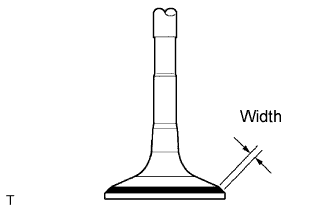

Check that the valve seat contact is in the middle of the valve face with the width between 1.0 to 1.4 mm (0.039 to 0.055 in.).

|

If the seating is too high on the valve face, use 30° and 45° cutters to correct the seat.

|

If the seating is too low on the valve face, use 60° and 45° cutters to correct the seat.

Hand rub the valve and valve seat with an abrasive compound.

Check the valve seating position.

| 3. BORE CYLINDER |

|

Keep 4 new O/S pistons.

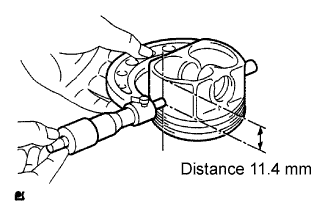

Using a micrometer, measure the piston diameter at right angles to the piston center line, the indicated distance from the piston end.

Calculate how much each cylinder needs to be rebored:

Bore and hone the cylinders to calculated dimensions.