EMISSION CONTROL SYSTEM > ON-VEHICLE INSPECTION |

| 1. CHECK FUEL CUT RPM |

Increase the engine speed to at least 3,500 rpm.

Use a sound scope to check for injector operation noise.

Check that when the throttle lever is released, injector operation noise stops momentarily and then resumes.

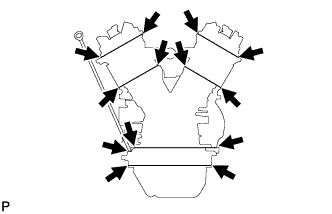

| 2. VISUALLY CHECK HOSES, CONNECTORS AND GASKETS |

|

Check that there are no cracks, leaks or damage.

| 3. CHECK HOSES AND CONNECTORS |

Visually check for loose connections, sharp bends or damage.

| 4. CHECK FUEL TANK ASSEMBLY |

Visually check for deformation, cracks or fuel leakage.