FUEL INJECTOR > INSTALLATION |

| 1. INSTALL INJECTOR ASSEMBLY |

|

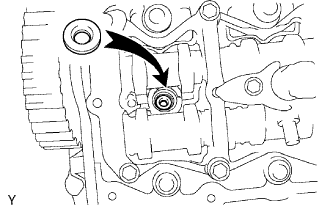

Install 4 new injection nozzle sheets to the cylinder head.

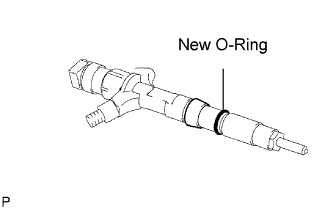

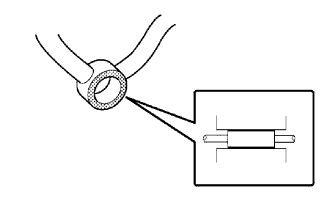

Apply a light amount of clean engine oil to 4 new O-rings.

|

Install the O-ring to each injector as shown in the illustration.

Insert the 4 injectors into the cylinder head.

Register injector compensation code (when replacing with a new injector).

|

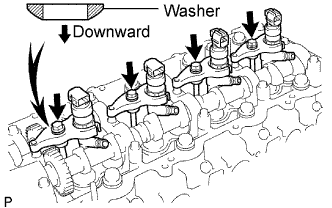

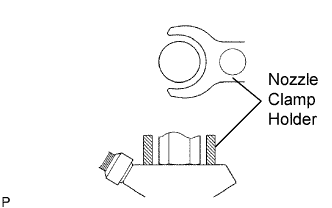

Temporarily install 4 new washers and the 4 nozzle clamps with the 4 clamp bolts.

Temporarily install the 4 injection pipes with the union nuts.

|

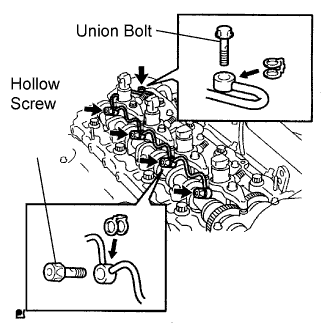

Check the nozzle leakage pipe. Check that there are no scratches or dents on the 5 union seal surfaces.

If scratches or dents are present, replace the nozzle leakage pipe.

|

Set the leakage pipe and 5 new gaskets in place.

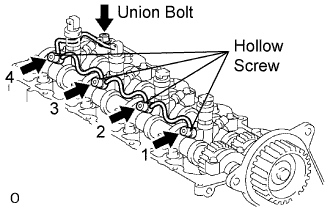

Apply a light amount of oil to the 4 hollow screws and union bolt.

|

Temporarily install the leakage pipe with the 4 hollow screws and union bolt.

Tighten the 4 holder clamp bolts.

|

Tighten the 4 hollow screws in order from 1 to 4.

Tighten the union bolt.

Remove the 4 injection pipes.

| 2. CHECK FOR FUEL LEAKS |

|

Check that there are no leaks from the nozzle leakage pipe connection.

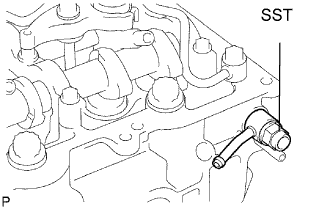

Install the gasket and No. 2 nozzle leakage pipe to the cylinder head with SST (check valve).

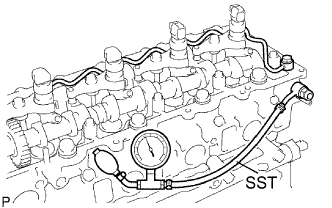

Apply a light amount of soapy water (or other fluid for detecting fuel leakage) on the nozzle leakage pipe connection.

|

Install SST (turbocharger pressure gauge) to the fuel return side of the leakage pipe, and maintain 250 kPa (2.5 kgf/cm2, 35.5 psi) of pressure for 60 seconds to check that no bubbles form.

After checking for fuel leaks, wipe off the soapy water from the leakage pipe connection.

Remove SST, No. 2 nozzle leakage pipe and gasket.

| 3. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

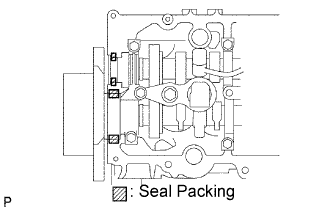

Remove any old seal packing (FIPG) material from the cylinder head.

|

Apply seal packing to the specific areas shown in the illustration.

|

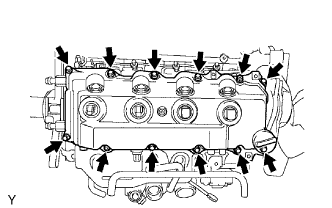

Install the gasket and cylinder head cover with the 10 bolts and 2 nuts.

Install 4 new nozzle holder seals.

| 4. INSTALL INJECTION PIPE |

|

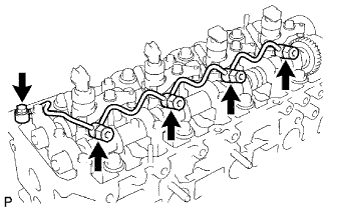

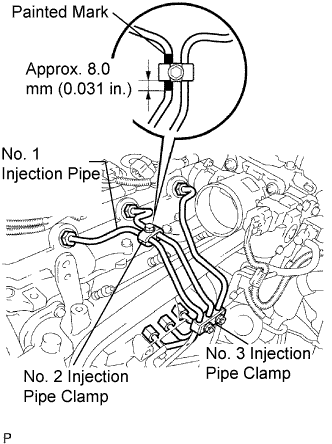

Temporarily install the No. 1, No. 2 and No. 3 injection pipes with the union nuts.

Install the No. 2 and No. 3 injection pipe clamps with the bolt and 2 nuts, as shown in the illustration.

|

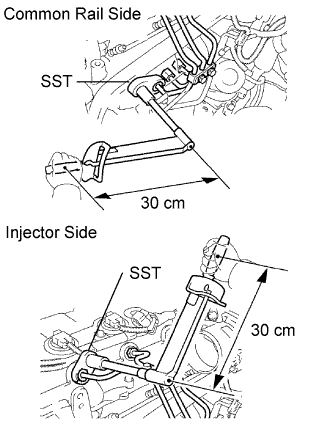

Using SST, tighten the injection pipe union nuts on the common rail side.

Using SST, tighten the injection pipe union nuts on the injector side.

|

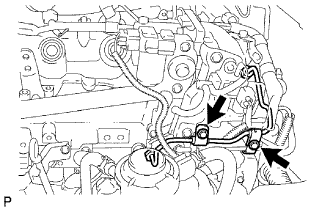

Temporarily install the No. 4 injection pipe with the union nuts.

Install 2 new injection pipe clamps with the 2 bolts.

|

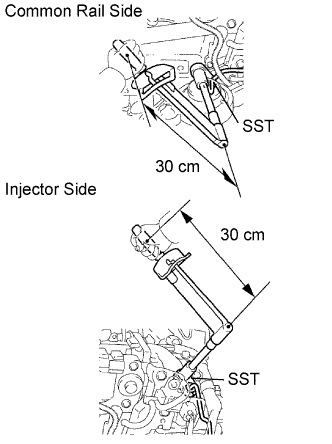

Using SST, tighten the injection pipe union nuts on the common rail side.

Using SST, tighten the injection pipe union nuts on the injector side.

| 5. INSTALL CHARGE AIR COOLER ASSEMBLY WITH INTAKE AIR CONNECTOR |

|

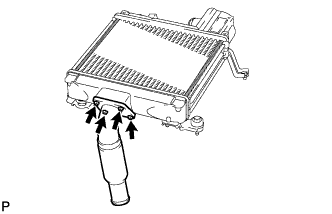

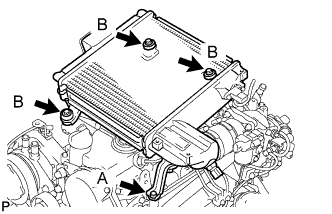

Install a new gasket and the intake air connector with the 4 bolts.

|

Using a 22 mm deep socket wrench, install a new gasket and the IAT sensor.

|

Install the CAC with the 4 bolts.

Tighten the 4 hose clamps of the No. 1 and No. 2 air hose.

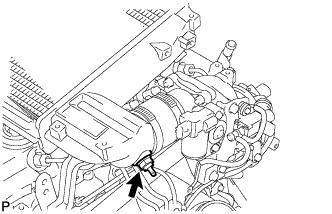

Connect the diesel turbo IAT sensor connector.

| 6. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY |

|

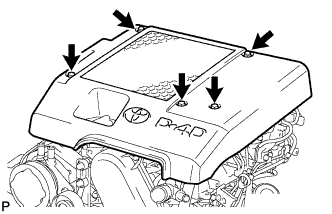

Install the cover with the 3 bolts and 2 nuts.

| 7. ADD FUEL |

| 8. TIGHTEN FUEL TANK CAP ASSEMBLY |

| 9. BLEED AIR FROM FUEL SYSTEM |

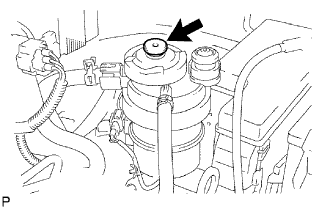

|

Using the hand pump, bleed air from the fuel system until pumping becomes difficult.

| 10. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 11. PERFORM INITIALIZATION |

Perform initialization (Click here).

| 12. REGISTER INJECTOR COMPENSATION CODE |

Register the injector compensation code (Click here).

| 13. CHECK FOR FUEL LEAKS |

| 14. CHECK FOR OIL LEAKS |