FUEL PRESSURE REGULATOR > INSTALLATION |

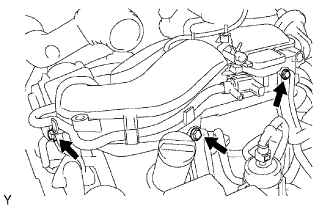

| 1. INSTALL FUEL PRESSURE REGULATOR ASSEMBLY |

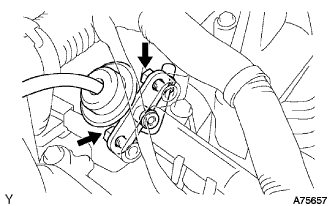

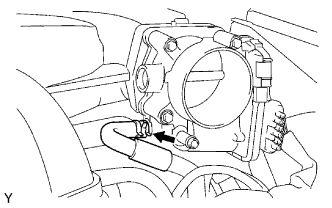

Install the vacuum hose.

Apply a light coat of spindle oil or gasoline to a new O-ring and install it to the fuel pressure regulator.

|

Install the fuel pressure regulator with the 2 bolts.

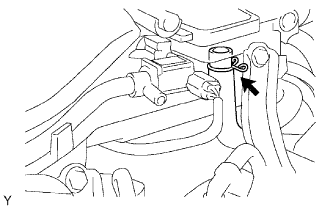

| 2. CONNECT NO. 2 FUEL PIPE SUB-ASSEMBLY |

Connect the fuel pipe.

|

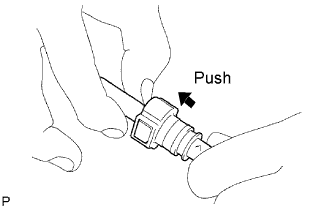

Check that there is no damage or contamination in the connected part of the pipe.

Align the axis of the connector with the axis of the pipe. Push the pipe into the connector until the connector makes a "click" sound. If the connection is tight, apply a little amount of fresh engine oil on the tip of the pipe.

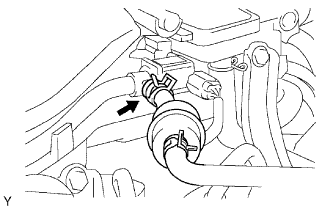

|

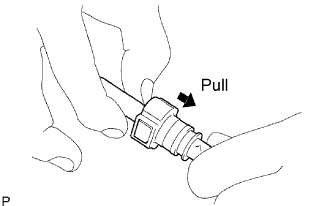

After having finished the connection, try to pull apart the pipe and the connector and confirm that they are securely connected.

Install the fuel pipe clamp.

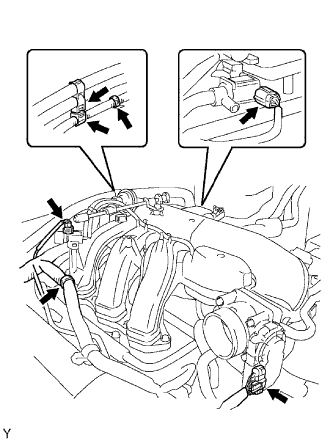

| 3. INSTALL INTAKE AIR SURGE TANK |

|

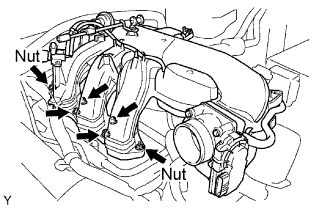

Install a new gasket and the surge tank with the 2 nuts.

Using an 8 hexagon wrench, install the 4 bolts.

|

Install the 3 upper bolts which are used to secure the 2 surge tank stays and throttle body bracket.

|

Install the 3 wire harness clamps and hose clamp.

Connect the throttle motor connector.

Connect the 2 VSV connectors.

|

Connect the ventilation hose.

|

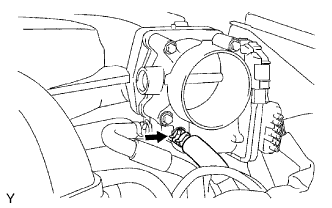

Connect the vapor feed hose assembly.

|

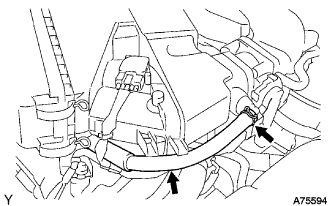

Connect the No. 4 water by-pass hose.

|

Connect the No. 5 water by-pass hose.

| 4. INSTALL AIR CLEANER ASSEMBLY |

| 5. CONNECT NO. 2 VENTILATION HOSE |

|

| 6. INSTALL V-BANK COVER |

Install the cover with the 2 nuts.

| 7. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 8. PERFORM INITIALIZATION |

Perform initialization (Click here).

| 9. CHECK FOR FUEL LEAKS |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON.

Push the intelligent tester main switch ON.

Select Active Test and enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

Check for fuel leaks.

Check that there are no fuel leaks after performing maintenance anywhere on the fuel system.