CYLINDER HEAD > INSPECTION |

| 1. CLEAN CYLINDER HEAD SUB-ASSEMBLY |

|

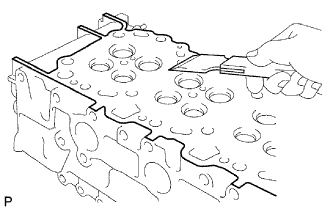

Clean the cylinder head.

Using a gasket scraper, remove all the gasket material from the cylinder block contact surface.

|

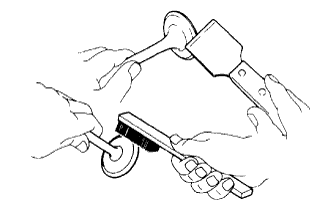

Using a wire brush, remove all the carbon from the combustion chambers.

|

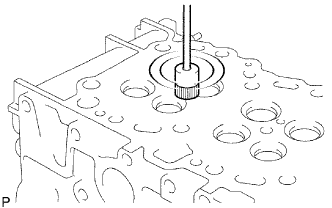

Using a valve guide bushing brush and solvent, clean all the guide bushes.

|

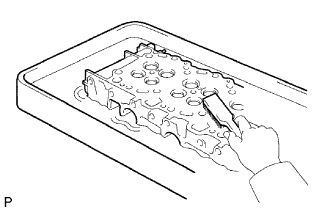

Using a soft brush and solvent, thoroughly clean the cylinder head.

| 2. INSPECT CYLINDER HEAD SUB-ASSEMBLY |

|

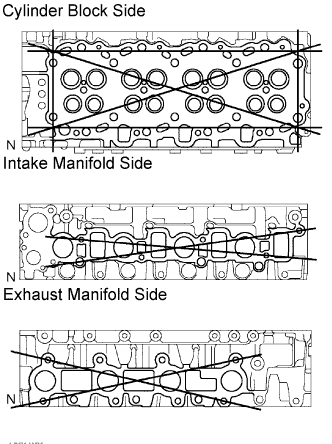

Inspect the cylinder head warpage.

Using a precision straightedge and feeler gauge, measure the surfaces contacting the cylinder block and the manifolds for warpage.

|

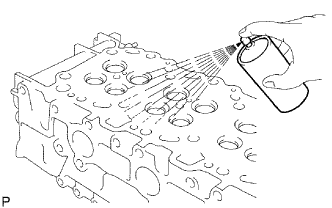

Inspect the cylinder head for cracks.

Using a dye penetrant, check the combustion chamber, intake ports, exhaust ports and cylinder block surface for cracks.

If cracked, replace the cylinder head.

| 3. CLEAN INTAKE VALVE |

|

Clean valves.

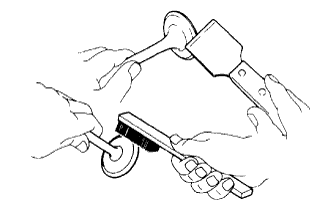

Using a gasket scraper, chip off any carbon from the valve head.

Using a wire brush, thoroughly clean the valve.

| 4. INSPECT INTAKE VALVE |

|

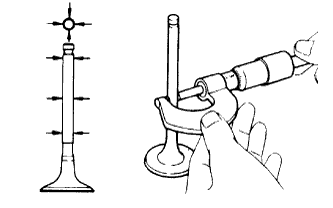

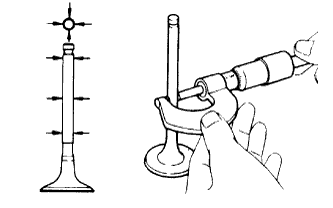

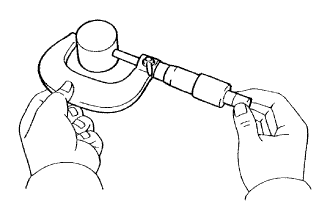

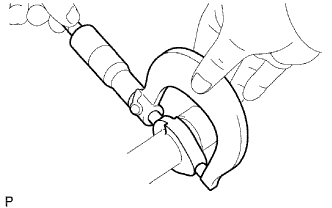

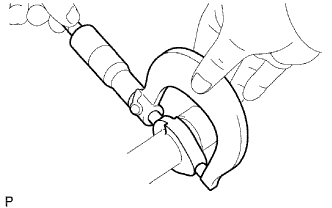

Using a micrometer, measure the diameter of the valve stem.

|

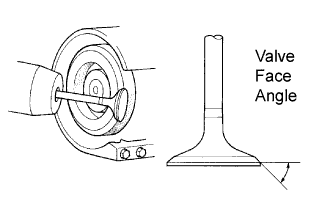

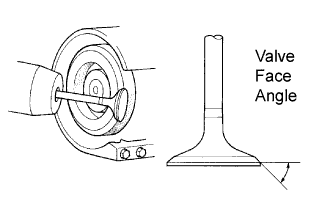

Check the valve face angle.

Grind the valve enough to remove pits and carbon.

Check that the valve is ground to the correct valve face angle.

|

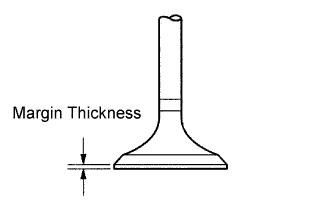

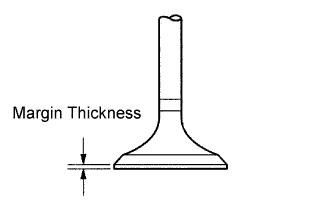

Check the valve head margin thickness.

|

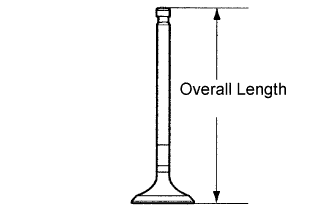

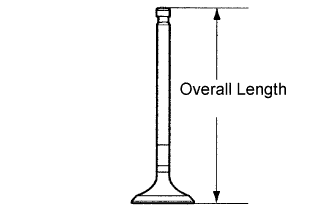

Check the valve overall length.

|

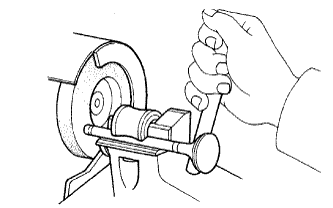

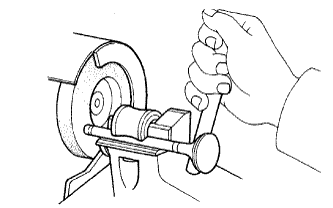

Check the surface of the valve stem tip for wear.

If the valve stem tip is worn, resurface the tip with a grinder or replace the valve.

| 5. CLEAN EXHAUST VALVE |

|

Clean the valves.

Using a gasket scraper, chip off any carbon from the valve head.

Using a wire brush, thoroughly clean the valve.

| 6. INSPECT EXHAUST VALVE |

|

Using a micrometer, measure the diameter of the valve stem.

|

Check the valve face angle.

Grind the valve enough to remove pits and carbon.

Check that the valve is ground to the correct valve face angle.

|

Check the valve head margin thickness.

|

Check the valve overall length.

|

Check the surface of the valve stem tip for wear.

If the valve stem tip is worn, resurface the tip with a grinder or replace the valve.

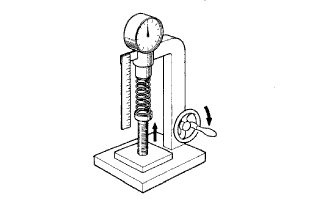

| 7. INSPECT COMPRESSION SPRING |

|

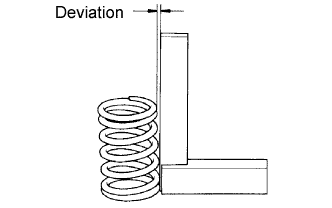

Using a steel square, measure the deviation of the spring.

|

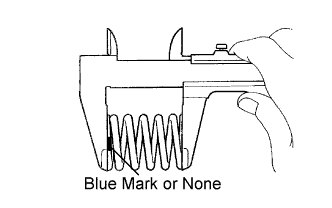

Using a vernier caliper, measure the free length of the spring.

| Blue Mark | None |

| 46.8 mm (1.843 in.) | 46.5 mm (1.831 in.) |

|

Using a spring tester, measure the tension of the valve spring at the specified installed length.

| Blue Mark | None |

| 149.9 to 166.1 N (15.3 to 16.9 kgf, 33.7 to 37.3 lbf) | 150.2 to 165.8 N (15.3 to 16.9 kgf, 33.7 to 37.3 lbf) |

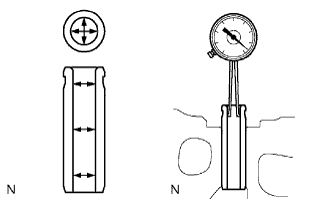

| 8. INSPECT INTAKE VALVE GUIDE BUSH |

|

Using a caliper gauge, measure the inside diameter of the guide bush.

Subtract the valve stem diameter measurement from the guide bush inside diameter measurement.

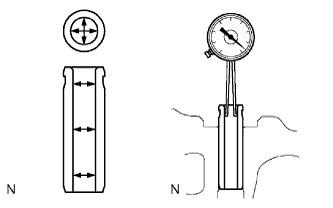

| 9. INSPECT EXHAUST VALVE GUIDE BUSH |

|

Using a caliper gauge, measure the inside diameter of the guide bush.

Subtract the valve stem diameter measurement from the guide bush inside diameter measurement.

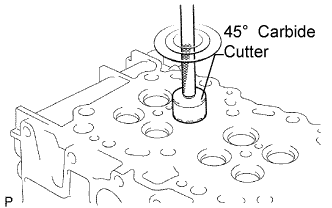

| 10. INSPECT INTAKE VALVE SEAT |

|

Using a 45° carbide cutter, resurface the valve seats. Remove only enough metal to clean the seats.

|

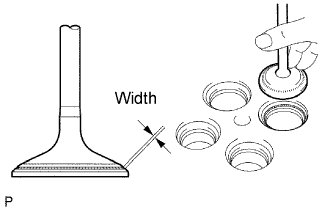

Check the valve seating position.

Apply a light coat of Prussian blue (or white lead) to the valve face.

Lightly press the valve against the seat. Do not rotate valve.

Check the valve face and seat for the following:

If blue appears 360° around the face, the valve is concentric. If not, replace the valve.

If blue appears 360° around the valve seat, the guide and face are concentric. If not, resurface the seat.

Check that the seat contact is in the middle of the valve face with the width below.

| 11. INSPECT EXHAUST VALVE SEAT |

|

Using a 45° carbide cutter, resurface the valve seats. Remove only enough metal to clean the seats.

|

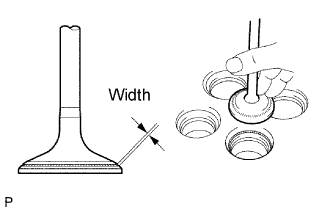

Check the valve seating position.

Apply a light coat of Prussian blue (or white lead) to the valve face.

Lightly press the valve against the seat. Do not rotate valve.

Check the valve face and seat for the following:

If blue appears 360° around the face, the valve is concentric. If not, replace the valve.

If blue appears 360° around the valve seat, the guide and face are concentric. If not, resurface the seat.

Check that the seat contact is in the middle of the valve face with the width below.

| 12. INSPECT VALVE LIFTER |

|

Using a micrometer, measure the lifter diameter.

|

Using a caliper gauge, measure the lifter bore diameter of the cylinder head.

Subtract the lifter diameter measurement from the lifter bore diameter measurement.

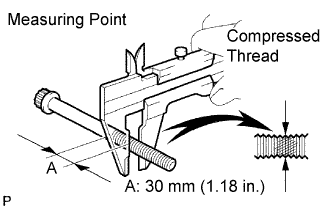

| 13. INSPECT CYLINDER HEAD SET BOLT |

|

Using a vernier caliper, measure the minimum outside diameter of the compressed thread at the measuring point A.

| 14. INSPECT CAMSHAFT |

|

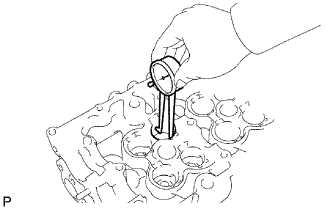

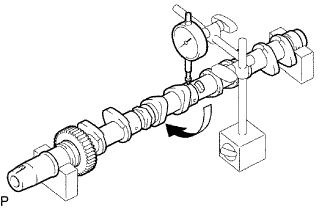

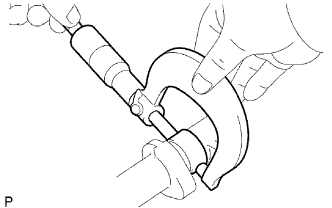

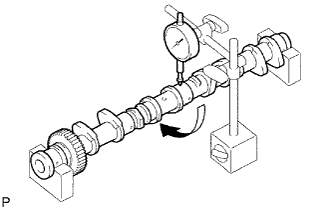

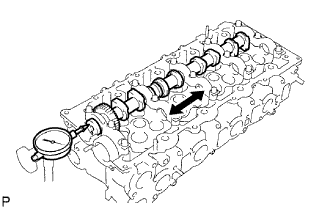

Inspect the circle runout.

Place the camshaft on V-blocks.

Using a dial indicator, measure the circle runout at the center journal.

|

Using a micrometer, measure the cam lobe height.

|

Inspect the journal diameter of the camshaft.

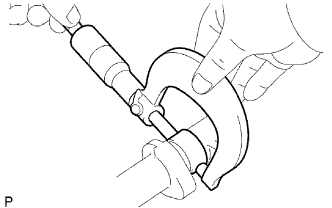

Using a micrometer, measure the journal diameter of the camshaft for the camshaft bearing.

|

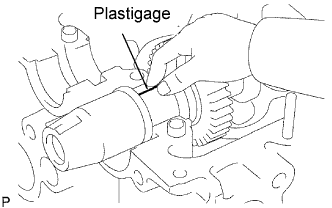

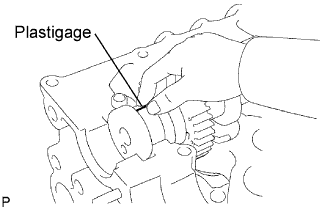

Check the oil clearance.

Clean the bearing caps and journals.

Check the bearings for flaking and scoring.

If the bearings are damaged, replace the bearing caps and cylinder head as a set.

Install the bearings to the bearing caps and cylinder head.

Place the camshaft on the cylinder head.

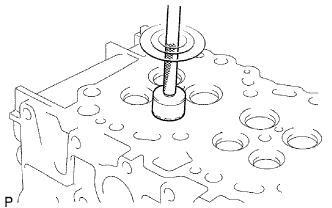

Lay a strip of Plastigage across each of the journals.

|

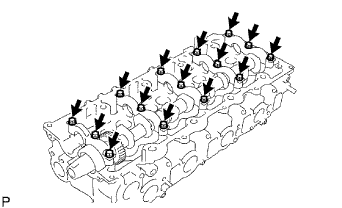

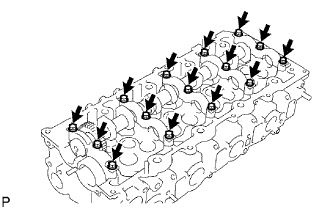

Install the bearing caps.

Remove the bearing caps.

|

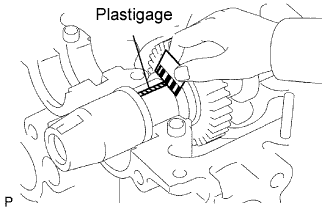

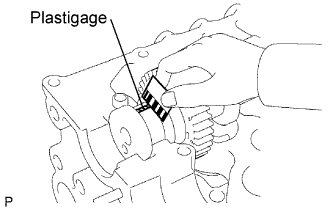

Measure the Plastigage at its widest point.

Completely remove the Plastigage.

Remove the camshaft.

|

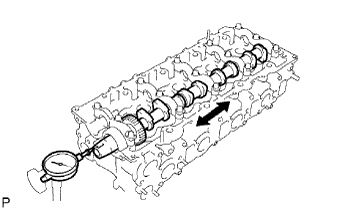

Check the thrust clearance.

Install the camshaft.

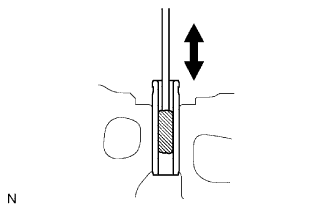

Using a dial indicator, measure the thrust clearance while moving the camshaft back and forth.

|

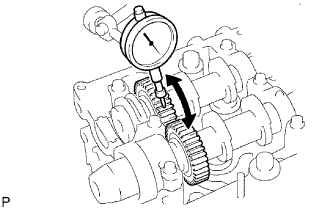

Using a dial indicator, measure the backlash.

Install the 2 camshafts.

Using a dial indicator, measure the backlash.

Remove the 2 camshafts.

| 15. INSPECT NO. 2 CAMSHAFT |

|

Inspect the circle runout.

Place the camshaft on V-blocks.

Using a dial indicator, measure the circle runout at the center journal.

|

Using a micrometer, measure the cam lobe height.

|

Inspect the journal diameter of the camshaft.

Using a micrometer, measure the journal diameter of the camshaft for the camshaft bearing.

|

Check the oil clearance.

Clean the bearing caps and journals.

Check the bearings for flaking and scoring.

If the bearings are damaged, replace the bearing caps and cylinder head.

Install the bearings to the bearing caps and cylinder head.

Place the camshaft on the cylinder head.

Lay a strip of Plastigage across each of the journals.

|

Install the bearing caps.

Remove the bearing caps.

|

Measure the Plastigage at its widest point.

Completely remove the Plastigage.

Remove the camshaft.

|

Check the thrust clearance.

Install the camshaft.

Using a dial indicator, measure the thrust clearance while moving the camshaft back and forth.