TIMING BELT > INSPECTION |

| 1. INSPECT TIMING BELT |

|

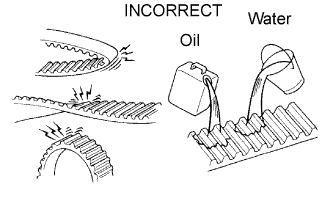

Visually inspect the timing belt.

If defects are present, perform the steps below.

Premature parting:

Check for proper installation.

Check the timing cover gasket for damage and proper installation.

If the belt teeth are cracked or damaged, check to see if either camshaft is locked.

If there is noticeable wear or cracks on the belt face, check if there are nicks on the side of the idler pulley lock and water pump.

If there is wear or damage on only one side of the belt, check the belt guide and the alignment of each pulley.

If there is noticeable wear on the belt teeth, check the timing cover for damage, check that the gasket has been installed correctly, and check for foreign material on the pulley teeth.

If necessary, replace the timing belt.

| 2. INSPECT NO. 1 TIMING BELT IDLER SUB-ASSEMBLY |

|

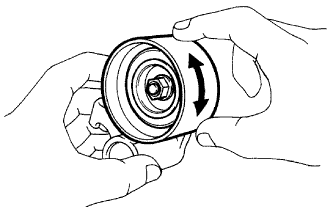

Check that the idler pulley turns smoothly by hand.

|

Visually check that the seal portion of the idler pulley has no grease on it.

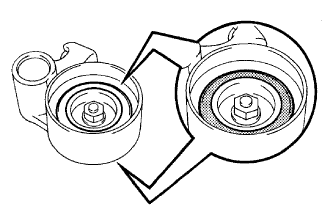

| 3. INSPECT NO. 1 TIMING BELT TENSIONER ASSEMBLY |

|

Visually check the seal portion of the tensioner for oil leakage.

If leakage is found, replace the tensioner.

|

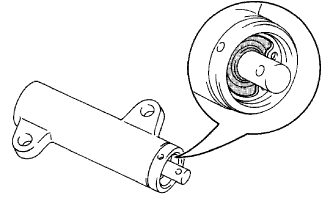

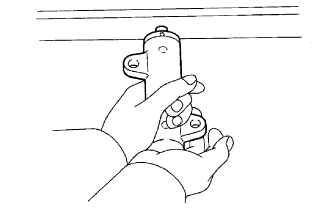

Hold the tensioner with both hands as shown in the illustration. Firmly push the push rod and check that it does not move.

If the push rod moves, replace the tensioner.

|

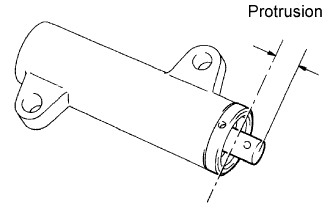

Measure the protrusion of the push rod from the housing end.