ENGINE > ON-VEHICLE INSPECTION |

| 1. CHECK ENGINE IDLE SPEED AND MAXIMUM SPEED |

|

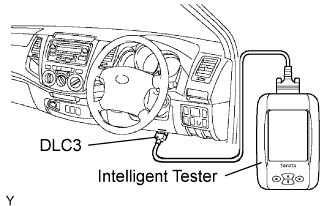

Connect the intelligent tester to the DLC3.

|

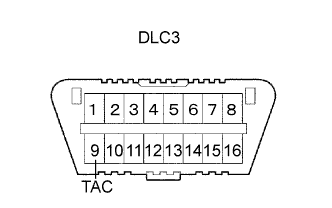

If a tester is not available, connect a tester probe of a tachometer to terminal 9 (TAC) of the DLC3 with SST.

Inspect the idle speed.

Start the engine and measure the idle speed.

Inspect the maximum speed.

Start the engine.

Fully depress the accelerator pedal.

Measure the maximum speed.

If the tester probe of the tachometer is connected to the DLC3, disconnect the tester probe with SST from terminal 9 of the DLC3.

Disconnect the intelligent tester from the DLC3.

| 2. INSPECT CYLINDER COMPRESSION PRESSURE |

Remove the 4 glow plugs.

Disconnect the 4 injector connectors.

Turn the ignition switch to START to expel soot and other foreign matter from the inside of the cylinder.

|

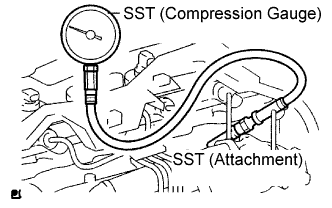

Measure the compression pressure.

Set SST (attachment) into the glow plug hole.

Connect SST (compression gauge) to SST (attachment).

Measure the compression pressure while cranking the engine.

Perform the step above for each cylinder.

Remove SST (attachment and compression gauge).

Connect the 4 injector connectors.

Install the 4 glow plugs.