TURBOCHARGER > INSPECTION |

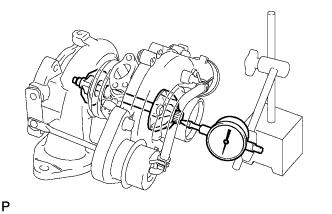

| 1. INSPECT AXIAL PLAY OF TURBINE SHAFT |

|

Using a dial indicator, insert the needle of the dial indicator into the exhaust side of the turbine shaft.

Move the turbine shaft in an axial direction and measure the axial play of the turbine shaft.

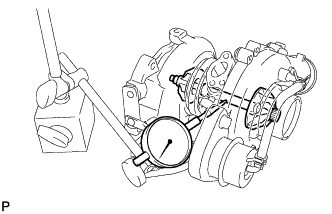

| 2. INSPECT RADIAL PLAY OF TURBINE SHAFT |

|

Using a dial indicator, insert the needle of the dial indicator into the oil outlet hole, and set it in the center of the turbine shaft.

Move the turbine shaft in a radial direction and measure the radial play of the turbine shaft.

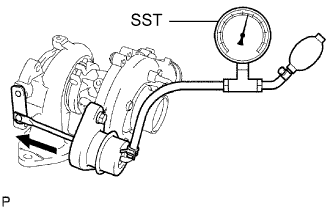

| 3. INSPECT ACTUATOR AND WASTE GATE VALVE OPERATION |

|

Disconnect the actuator hose from the compressor housing.

Using SST, apply pressure to the actuator.

Check that the actuator push rod moves and that the waste gate valve opens.

If the rod does not move, replace the actuator or turbocharger sub-assembly.

Connect the actuator hose to the compressor housing.