TURBOCHARGER > INSTALLATION |

| 1. CLEAN TURBOCHARGER SUB-ASSEMBLY |

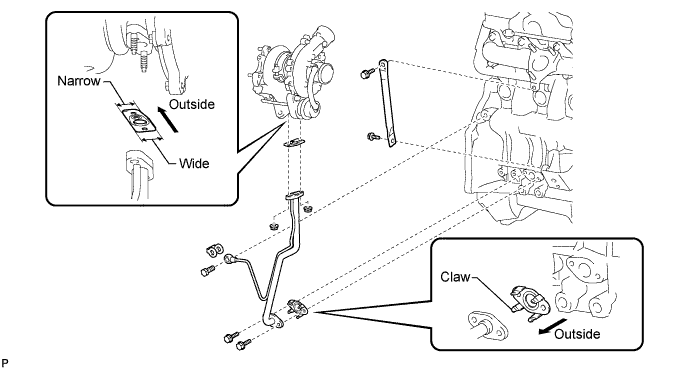

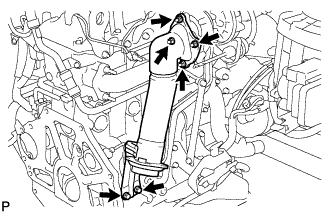

| 2. INSTALL TURBOCHARGER SUB-ASSEMBLY |

|

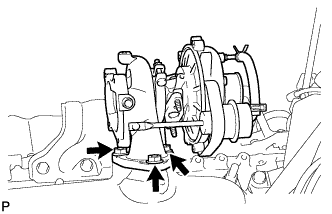

Temporarily install a new gasket and the turbocharger with 3 new nuts.

Temporarily install the turbo oil pipe and manifold stay.

|

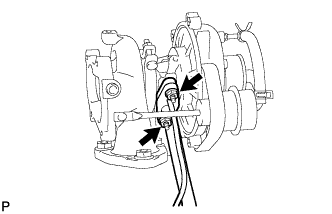

Temporarily install a new gasket and the oil pipe with the 2 nuts, but only loosely install the nuts.

|

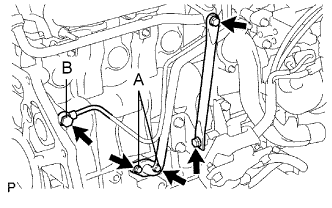

Temporarily install a new gasket and the oil pipe with the 2 bolts (labeled: A), but only loosely install the bolts.

Temporarily install a new gasket and the oil pipe with the union bolt (labeled: B), but only loosely install the union bolt.

Temporarily install the stay with the 2 bolts.

Tighten the bolts and nuts.

Tighten the 3 nuts of the turbocharger.

Tighten the 2 nuts of the oil pipe.

Tighten the 2 bolts of the oil pipe.

Tighten the union bolt.

Tighten the 2 bolts of the stay.

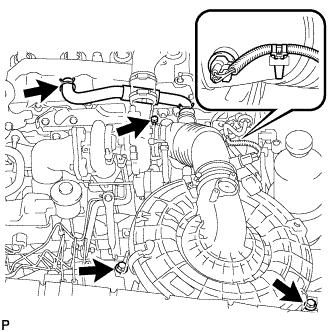

| 3. INSTALL TURBINE OUTLET ELBOW |

|

Temporarily install a new gasket and the outlet elbow (with turbocharger stay) to the turbocharger with the 4 nuts.

Temporarily install the stay with the 2 bolts.

Tighten the 4 nuts of the turbocharger.

Tighten the 2 bolts of the stay.

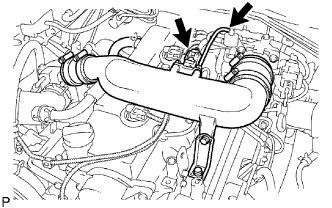

| 4. INSTALL AIR CLEANER PIPE SUB-ASSEMBLY |

|

Connect the pipe (with the 2 air hoses) and install the bolt.

Tighten the 2 clamps of the No. 1 and No. 2 air hoses.

Connect the vacuum hose to the gas filter.

Connect the manifold absolute pressure sensor connector.

| 5. INSTALL VENTILATION HOSE HEAT INSULATOR |

Install the insulator with the 2 bolts.

| 6. INSTALL AIR CLEANER ASSEMBLY |

|

Connect the air cleaner hose.

Install the air cleaner with the 2 bolts.

Tighten the clamp.

Install the clamp and connect the IAT connector.

Connect the ventilation hose.

Slide the clamp to the connection of the hose.

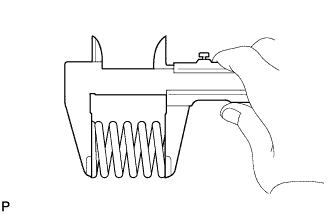

| 7. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

|

Using a vernier caliper, measure the free length of the compression spring.

Install the front pipe to the pipe support.

|

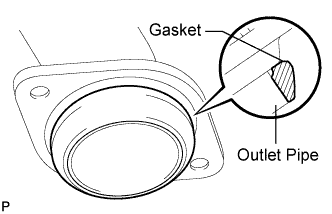

Install a new gasket to the outlet pipe.

Install the front pipe with the 2 compression springs and 2 bolts. Alternately tighten the bolts in several passes.

| 8. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 9. CHECK FOR ENGINE OIL LEAKS |

| 10. CHECK FOR EXHAUST LEAKS |

| 11. INSTALL FRONT FENDER APRON SEAL UPPER |

Install the apron seal with the 5 clips.

| 12. INSTALL FRONT FENDER SEAL |

Install the fender seal with the 5 clips.

| 13. INSTALL FRONT WHEEL RH |

| 14. INSTALL NO. 1 ENGINE UNDER COVER |

Install the cover with the 4 bolts.

| 15. PERFORM INITIALIZATION |

Perform initialization (Click here).