INTAKE MANIFOLD > INSPECTION |

| 1. INSPECT INTAKE MANIFOLD |

|

|

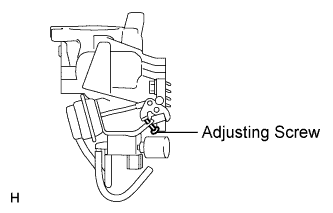

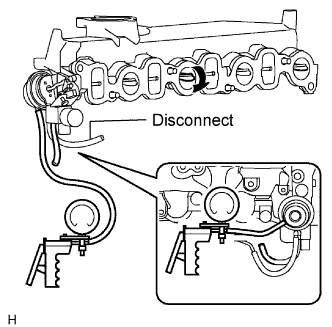

Disconnect the vacuum hose from the actuator.

Check the operation of the swirl control valve.

Check that the valve is fully opened under normal conditions.

Connect a vacuum pump to the control valve. Check that the valve is fully closed when a negative pressure of 35 kPa (270 mmHg, 10 in.Hg) is applied.

Leave it for 1 minute and check that the vacuum pump needle does not move.

If the result is not as specified, replace the intake manifold.

| 2. INSPECT VACUUM SWITCHING VALVE (for SWIRL CONTROL VALVE) |

|

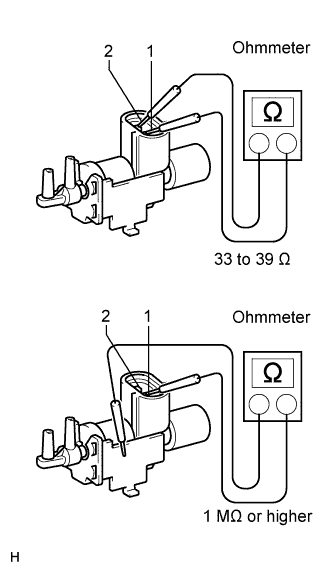

Measure the resistance of the VSV.

| Tester Connection | Specified Condition |

| 1 - 2 | 33 to 39 Ω at 20°C (68°F) |

| 1 - Body ground 2 - Body ground | 1 MΩ or higher |

|

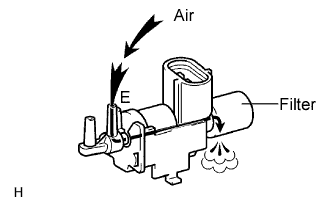

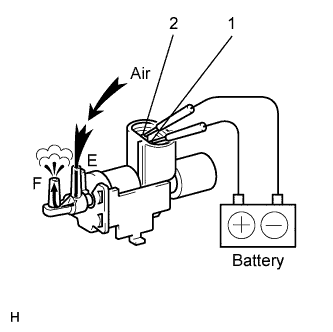

Check the operation of the VSV.

Check that air flows from port E to the filter.

If the result is not as specified, replace the VSV assembly.

|

Apply battery voltage across the terminals.

Check that air flows from port E to port F.

If the result is not as specified, replace the VSV assembly.