EMISSION CONTROL SYSTEM (for Unleaded Gasoline Specification Vehicle) > ON-VEHICLE INSPECTION |

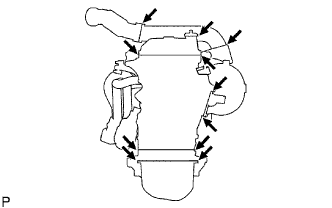

| 1. VISUALLY CHECK HOSES, CONNECTIONS AND GASKETS |

|

Check that there are no cracks, leaks or damage.

| 2. CHECK VACUUM SWITCHING VALVE (for EVAP) |

|

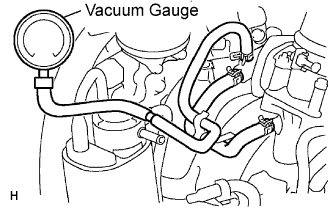

Check that the vacuum hose is connected correctly.

Disconnect the vacuum hose from the canister, and connect a vacuum gauge.

Using the flowchart below, perform a VSV operation inspection when the engine coolant temperature is 55°C (131°F) or less (while the engine is cold (VSV is closed)).

VSV operation flowchart.

1. When engine is idling or running and at 2,500 rpm, the vacuum gauge indicates 1 kPa (25 mmHg, 0.3 in.Hg) or less.

| Result | Procedure |

| Yes | VSV operation normal |

| No | Go to next step |

| Result | Procedure |

| OK | Check wire harness and ECM |

| NG | Replace VSV |

Using the flowchart below, perform a VSV operation inspection when the engine coolant temperature is 80°C (146°F) or more (while the engine is hot (VSV is opened)).

VSV operation flowchart.

1. When engine is idling, the vacuum gauge indicates 40 kPa (300 mmHg, 11.8 in.Hg) or more.

| Result | Procedure |

| Yes | VSV operation normal |

| No | Go to next step |

| Result | Procedure |

| OK | Check wire harness and ECM |

| NG | Replace VSV |