Item

| Measurement Item/

Range (Display)

| Normal Condition

| Diagnostic Note

|

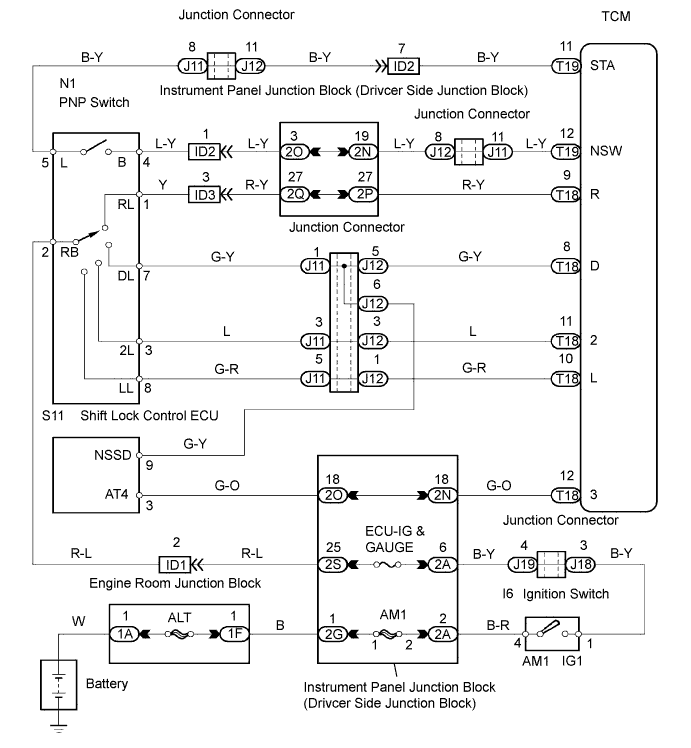

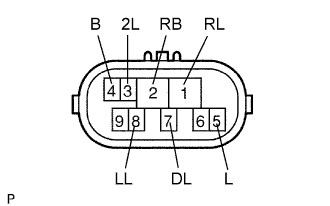

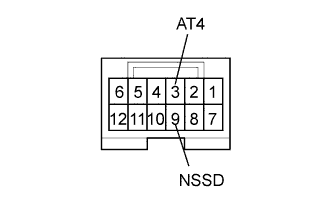

Neutral Position SW Signal

| PNP switch status/

ON or OFF

| Shift lever is:

On P or N: ON

Not on P or N: OFF

| When shift lever position displayed on Intelligent tester differs from actual position, adjustment of PNP switch or shift cable may be incorrect

- HINT:

- When failure still occurs even after adjusting these parts

|

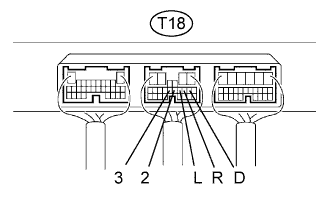

Shift SW Status (R Range)

| PNP switch status/

ON or OFF

| Shift lever is:

On R: ON

Not on R: OFF

| When shift lever position displayed on Intelligent tester differs from actual position, adjustment of PNP switch or shift cable may be incorrect

- HINT:

- When failure still occurs even after adjusting these parts

|

Shift SW Status (D or 3 Range)

| PNP switch status/

ON or OFF

| Shift lever is:

On D or 3: ON

Not on D or 3: OFF

| When shift lever position displayed on Intelligent tester differs from actual position, adjustment of PNP switch or shift cable may be incorrect

- HINT:

- When failure still occurs even after adjusting these parts

|

Shift SW Status (2 Range)

| PNP switch status/

ON or OFF

| Shift lever is:

On 2: ON

Not on 2: OFF

| When shift lever position displayed on Intelligent tester differs from actual position, adjustment of PNP switch or shift cable may be incorrect

- HINT:

- When failure still occurs even after adjusting these parts

|

Shift SW status (L Range)

| PNP switch status/

ON or OFF

| Shift lever is:

On L: ON

Not on L: OFF

| When shift lever position displayed on Intelligent tester differs from actual position, adjustment of PNP switch or shift cable may be incorrect

- HINT:

- When failure still occurs even after adjusting these parts

|