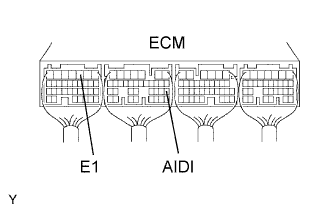

AID Diagnostic Signal Waveform

| ECM Command

| DTC

(ECM Output)

| Suspected Trouble Area

|

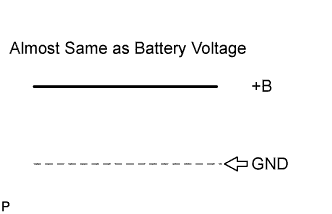

100% Duty Ratio

See waveform 1

| Any Air Injection (AI) System operation

| P1613

| - Open in diagnostic signal circuit

- Air Injection Control Driver (AID)

- Open in AID +B circuit (AID power source)

- Short between +B circuit and diagnostic signal circuit

|

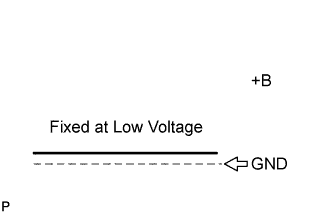

0% Duty Ratio

See waveform 2

| AI System: ON

(Air pump ON, ASV ON)

| P1613

| - Open or short in air pump or Air Switching Valve (ASV) command signal circuit (ECM - AID)

- Open in AID ground circuit

- Short between diagnostic signal circuit and body ground

- AID

- ECM

|

AI System: OFF

(Air pump OFF, ASV OFF)

| -

| - Normal

|

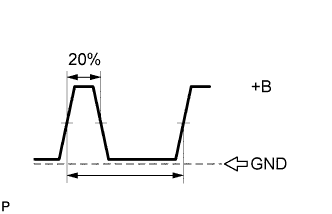

20% Duty Ratio

See waveform 3

| Air Pump: ON

| P0418

| - Short between air pump drive circuit and body ground

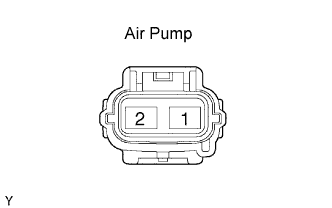

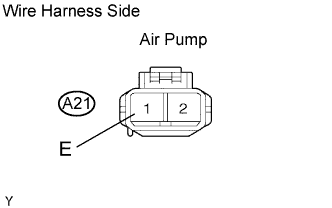

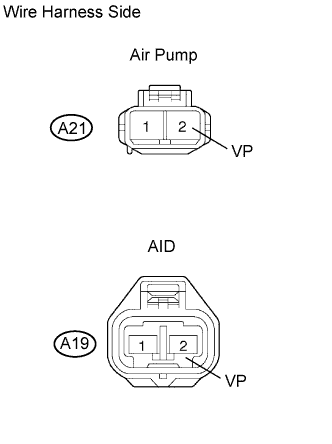

- Harness & connector (AID - Pump)

- Air Pump

- AID

- ECM

|

Air Pump: OFF

| P0418

| - Open in air pump drive circuit (AID - Pump), or short between air pump drive circuit and +B

- Harness & connector (AID - Pump)

- Air Pump

- AID

- ECM

|

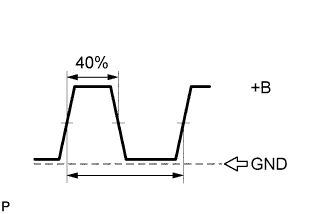

40% Duty Ratio

See waveform 4

| ASV: ON

| P0412

| - Short between ASV drive circuit and body ground

- Harness & connector (AID - ASV)

- ASV

- AID

- ECM

|

ASV: OFF

| P0412

| - Open in ASV drive circuit (AID - ASV), or short between ASV drive circuit and +B

- Harness & connector (AID - ASV)

- AID

- ASV

- ECM

|

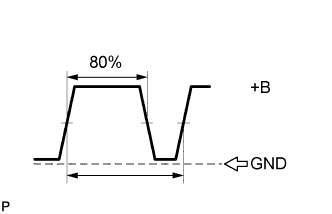

80% Duty Ratio

See waveform 5

| AI System: OFF

(Air pump OFF, ASV OFF)

| P1613

| - AID

- ECM

|

AI System: ON

(Air pump ON, ASV ON)

| -

| - Normal

|

Excluding Above

(excluding 0, 20, 40, 80, 100% duty)

| -

| P1613

| - AID

- Open in AID ground circuit

|