CLUTCH DRUM AND INPUT SHAFT ASSEMBLY > INSPECTION |

| 1. INSPECT REAR CLUTCH DISC |

|

Replace all discs if one of the following problems is present: 1) a disc, plate or flange is worn or burnt, 2) the lining of a disc is peeled off or discolored, or 3) grooves or printed numbers have even a little bit of damage.

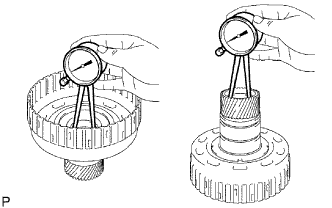

| 2. INSPECT REVERSE CLUTCH HUB SUB-ASSEMBLY |

|

Using a dial indicator, measure the inside diameter of the reverse clutch hub bushing.

| 3. INSPECT FORWARD CLUTCH HUB SUB-ASSEMBLY |

|

Using a dial indicator, measure the inside diameter of the forward clutch hub bushing.

| 4. INSPECT FORWARD MULTIPLE DISC CLUTCH DISC |

|

Replace all discs if one of the following problems is present: 1) a disc, plate or flange is worn or burnt, 2) the lining of a disc is peeled off or discolored, or 3) grooves or printed numbers have even a little bit of damage.

| 5. INSPECT FORWARD CLUTCH RETURN SPRING SUB-ASSEMBLY |

|

Using a vernier caliper, measure the free length of the spring together with the spring seat.

| 6. INSPECT DIRECT CLUTCH DISK |

|

Replace all discs if one of the following problems is present: 1) a disc, plate or flange is worn or burnt, 2) the lining of a disc is peeled off or discolored, or 3) grooves or printed numbers have even a little bit of damage.

| 7. INSPECT REVERSE CLUTCH RETURN SPRING SUB-ASSEMBLY |

|

Using a vernier caliper, measure the free length of the spring together with the spring seat.

| 8. INSPECT DIRECT CLUTCH RETURN SPRING SUB-ASSEMBLY |

|

Using a vernier caliper, measure the free length of the spring together with the spring seat.

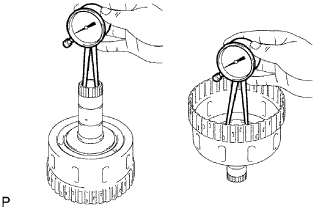

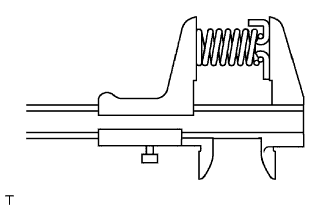

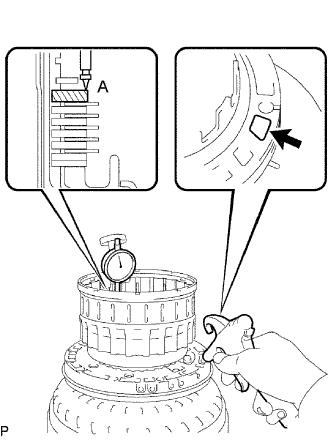

| 9. INSPECT PACK CLEARANCE OF DIRECT CLUTCH |

|

Using a dial gauge, measure the moving distance (distance A) of the clutch flange at both ends across a diameter while blowing air from the oil hole as shown in the illustration, and calculate the average.

If the pack clearance is outside the standard, select and install a clutch flange that makes the pack clearance within the standard.

| No. | Thickness | No. | Thickness |

| 0 | 3.0 mm (0.118 in.) | 5 | 3.5 mm (0.138 in.) |

| 1 | 3.1 mm (0.122 in.) | 6 | 3.6 mm (0.142 in.) |

| 2 | 3.2 mm (0.126 in.) | 7 | 3.7 mm (0.146 in.) |

| 3 | 3.3 mm (0.130 in.) | 8 | 3.8 mm (0.150 in.) |

| 4 | 3.4 mm (0.134 in.) | - | - |

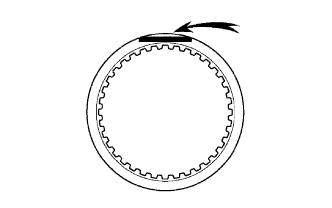

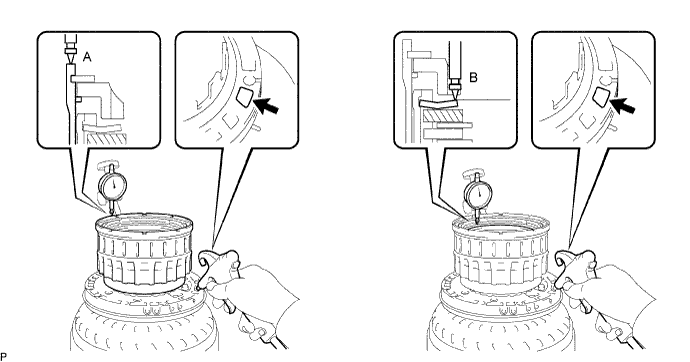

| 10. INSPECT PACK CLEARANCE OF REVERSE CLUTCH |

Using a dial gauge, measure the reverse clutch piston stroke (distance A) and the moving distance (distance B) of the reverse flange at the both ends across a diameter while blowing air (392 kPa, 4 kgf/cm2, 57 psi) from the oil hole as shown in the illustration, and calculate the average.

If the pack clearance is outside the standard, select and install a clutch flange that makes the pack clearance within the standard.

| No. | Thickness | No. | Thickness |

| 0 | 2.8 mm (0.110 in.) | 6 | 3.4 mm (0.134 in.) |

| 1 | 2.9 mm (0.114 in.) | 7 | 3.5 mm (0.138 in.) |

| 2 | 3.0 mm (0.118 in.) | 8 | 3.6 mm (0.142 in.) |

| 3 | 3.1 mm (0.122 in.) | 9 | 3.7 mm (0.146 in.) |

| 4 | 3.2 mm (0.126 in.) | A | 3.8 mm (0.150 in.) |

| 5 | 3.3 mm (0.130 in.) | - |

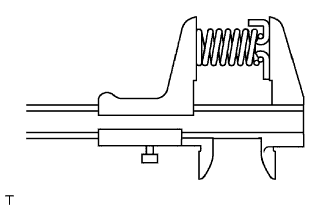

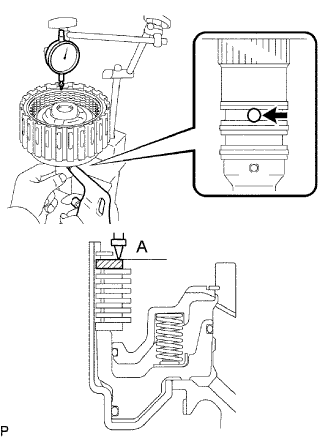

| 11. INSPECT PACK CLEARANCE OF FORWARD CLUTCH |

|

Using a dial gauge, measure the moving distance (distance A) of the clutch flange at boths end across a diameter while blowing air from the oil hole as shown in the illustration, and calculate the average.

If the pack clearance is outside the standard, select and install a clutch flange that makes the pack clearance within the standard.

| No. | Thickness | No. | Thickness |

| 0 | 3.0 mm (0.118 in.) | 6 | 3.6 mm (0.142 in.) |

| 1 | 3.1 mm (0.122 in.) | 7 | 3.7 mm (0.146 in.) |

| 2 | 3.2 mm (0.126 in.) | 8 | 3.8 mm (0.150 in.) |

| 3 | 3.3 mm (0.130 in.) | 9 | 3.9 mm (0.154 in.) |

| 4 | 3.4 mm (0.134 in.) | A | 4.0 mm (0.158 in.) |

| 5 | 3.5 mm (0.138 in.) | - |