OVERDRIVE BRAKE > DISASSEMBLY |

| 1. INSPECT PISTON OPERATION OF OVERDRIVE BRAKE |

|

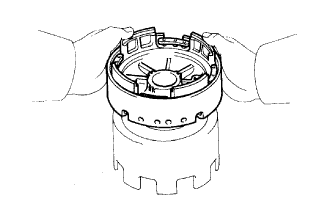

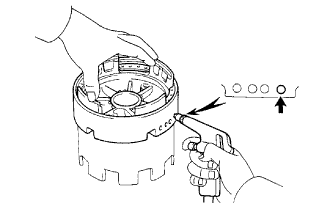

Place the overdrive support assembly onto the direct clutch assembly.

|

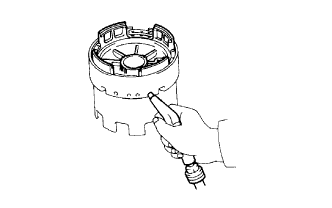

Apply compressed air (392 kPa (4 kgf/cm2, 57 psi)) into the oil passage, and check that the overdrive brake piston moves smoothly.

| 2. REMOVE OVERDRIVE BRAKE RETURN SPRING |

|

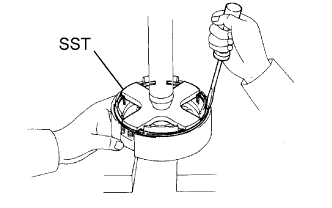

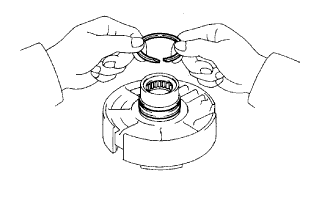

Place SST on the retainer spring, and compress the return spring with a press.

Using a screwdriver, pry out the snap ring.

Remove the brake return spring.

| 3. INSPECT OVERDRIVE BRAKE RETURN SPRING |

|

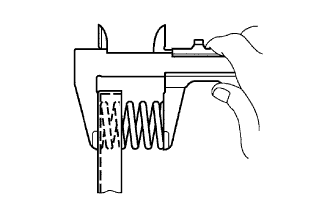

Using a vernier caliper, measure the free length of the spring together with the spring seat.

| 4. REMOVE OVERDRIVE BRAKE PISTON |

|

Place the overdrive support onto the direct clutch assembly.

Hold the overdrive brake piston so that it does not slant, and apply compressed air (392 kPa (4 kgf/cm2, 57 psi)) into the passage to remove the overdrive brake piston.

Remove the overdrive brake piston.

|

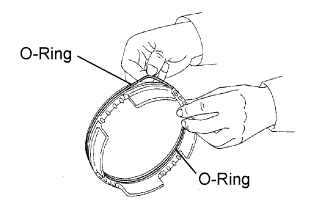

Remove the 2 O-rings.

| 5. REMOVE OVERDRIVE CLUTCH DRUM OIL SEAL RING |

|

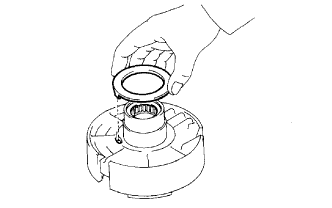

Remove the 2 oil seal rings.

|

Remove clutch drum thrust washer from overdrive support.

| 6. INSPECT OVERDRIVE BRAKE CLUTCH DISC |

|

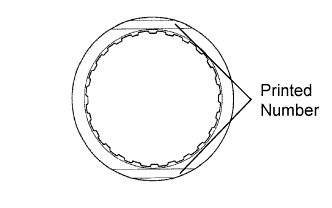

Replace all discs if one of the following problems is present: 1) a disc, plate or flange is worn or burnt, 2) the lining of a disc is peeled off or discolored, or 3) grooves or printed numbers have even a little bit of damage.