AUTOMATIC TRANSMISSION UNIT > INSPECTION |

| 1. INSPECT AUTOMATIC TRANSMISSION OIL PAN SUB-ASSEMBLY |

|

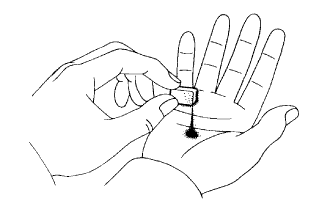

Remove the magnets and use them to collect steel particles.

Carefully look at the foreign matter and particles in the pan and on the magnets to anticipate the type of wear you will find in the transmission.

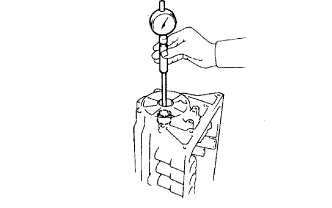

| 2. INSPECT OVERDRIVE BRAKE PISTON |

|

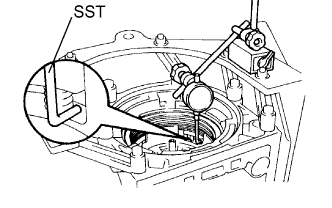

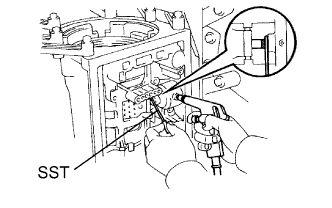

Place SST and a dial indicator onto the overdrive brake piston.

|

Measure the stroke while applying and releasing compressed air (392 kPa (4.0 kgf/cm2, 57 psi)).

| No. | Thickness | No. | Thickness |

| 77 | 3.3 mm (0.130 in.) | 81 | 3.8 mm (0.150 in.) |

| 78 | 3.5 mm (0.138 in.) | 82 | 3.9 mm (0.154 in.) |

| 79 | 3.6 mm (0.142 in.) | 83 | 4.0 mm (0.157 in.) |

| 80 | 3.7 mm (0.146 in.) |

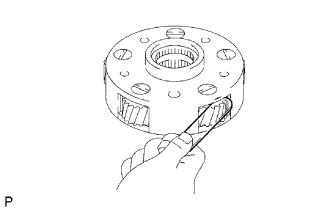

| 3. INSPECT FRONT PLANETARY RING GEAR |

|

Using a dial indicator, measure the inside diameter of the planetary ring gear bush.

| 4. INSPECT FRONT PLANETARY PINION GEAR THRUST CLEARANCE |

|

Using a feeler gauge, measure the pinion gear thrust clearance.

| 5. INSPECT PACK CLEARANCE OF 1ST AND REVERSE BRAKE |

|

Using a feeler gauge, measure the clearance between the plate and 2nd brake drum.

| No. | Thickness | No. | Thickness |

| 67 | 5.4mm (0.213 in.) | 52 | 4.6 mm (0.181 in.) |

| 66 | 5.2 mm (0.205 in.) | 53 | 4.4 mm (0.173 in.) |

| 50 | 5.0 mm (0.197 in.) | 54 | 4.2 mm (0.165 in.) |

| 51 | 4.8 mm (0.189 in.) | 55 | 4.0 mm (0.157 in.) |

| 6. INSPECT PACK CLEARANCE OF 2ND BRAKE |

|

Using a feeler gauge, measure the clearance between the snap ring and flange.

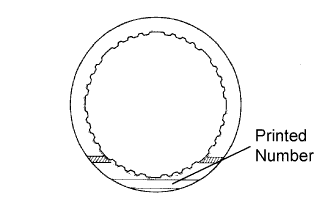

| 7. INSPECT 1ST AND REVERSE BRAKE CLUTCH DISC |

|

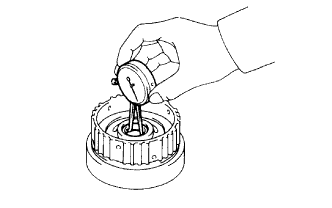

Replace all discs if one of the following problems is present: 1) a disc, plate or flange is worn or burnt, 2) the lining of a disc is peeled off or discolored, or 3) grooves or printed numbers have even a little bit of damage.

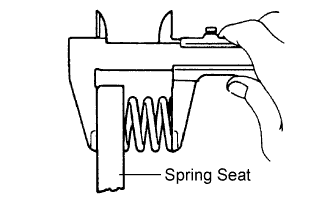

| 8. INSPECT 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY |

|

Using a vernier caliper, measure the free length of the spring together with the spring seat.

| 9. INSPECT TRANSMISSION CASE BUSHING |

|

Using a cylinder gauge, measure the inside diameter of the transmission case rear bush.

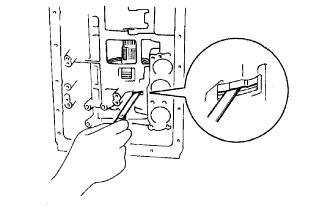

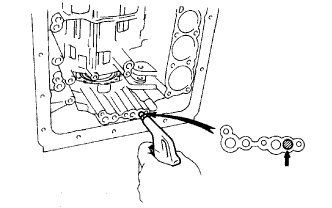

| 10. INSPECT PISTON STROKE OF 1ST AND REVERSE BRAKE |

|

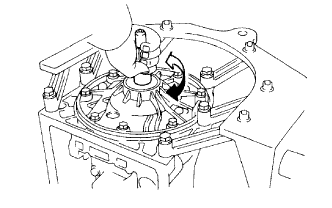

Make sure the 1st and reverse brake pistons move smoothly when compressed air is applied into the transmission case.

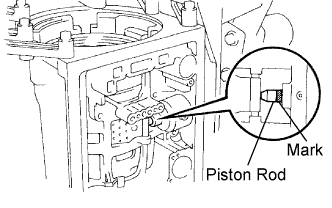

| 11. INSPECT PISTON STROKE OF 2ND COAST BRAKE |

|

Place a mark on the 2nd coast brake piston rod.

|

Using SST, measure the stroke while applying and releasing compressed air (392 kPa (4.0 kgf/cm2, 57 psi)).

| 12. INSPECT OUTPUT SHAFT |

|

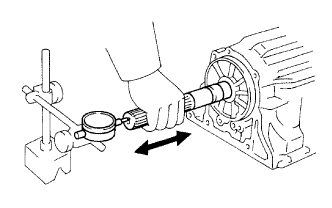

Using a dial indicator, measure the end play of the output shaft with hand.

Check that the output shaft rotates smoothly.

| 13. INSPECT INPUT SHAFT SUB-ASSEMBLY |

|

Make sure the input shaft rotates smoothly.

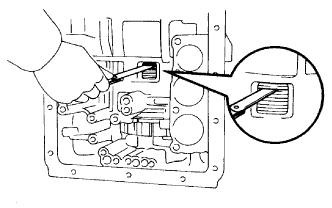

| 14. CHECK INDIVIDUAL PISTON OPERATION |

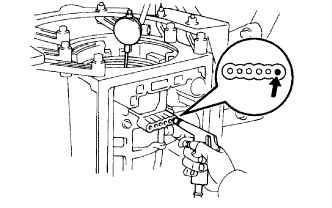

|

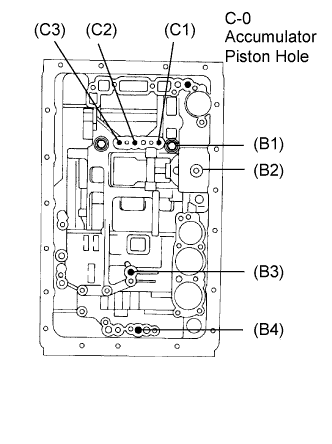

Check the operating sound while applying compressed air into the oil hole indicated in the illustration.

Overdrive direct clutch (C1)

Direct clutch (C2)

Forward clutch (C3)

Overdrive brake (B1)

2nd coast brake (B2)

2nd brake (B3)

1st and reverse brake (B4)