VALVE BODY ASSEMBLY > INSTALLATION |

| 1. INSTALL TRANSMISSION VALVE BODY ASSEMBLY |

|

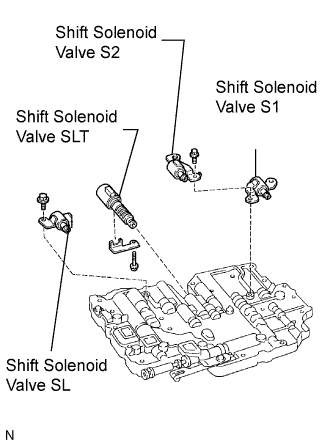

Install the shift solenoid valve SL with the bolt.

Install the shift solenoid valve S1 and S2 with the bolt.

Install the shift solenoid valve SLT with the plate and bolt.

|

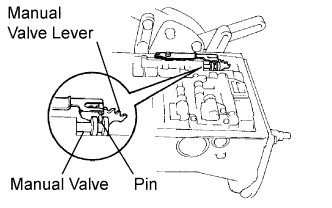

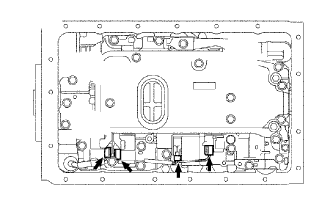

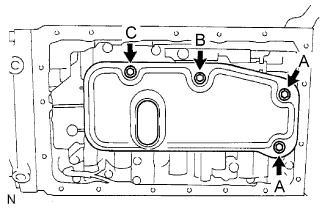

Align the groove of the manual valve with the pin of the lever.

|

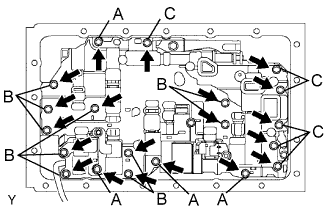

Install the 20 bolts.

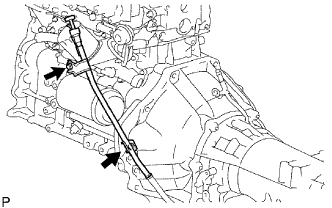

| 2. INSTALL TRANSMISSION WIRE |

|

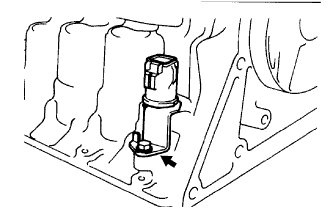

Coat a new O-ring with ATF and install it to the transmission wire.

Install the transmission wire to the case, and install the stopper plate with the bolt.

|

Connect the 4 connectors to the 4 shift solenoid valves.

| 3. INSTALL VALVE BODY OIL STRAINER ASSEMBLY |

|

Install 5 new gaskets.

Install the oil strainer with the 4 bolts.

| 4. INSTALL AUTOMATIC TRANSMISSION OIL PAN SUB-ASSEMBLY |

|

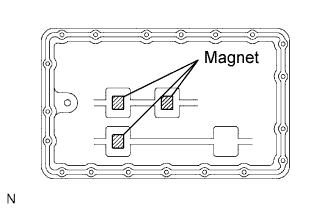

Install the 3 magnets to the locations indicated in the illustration.

|

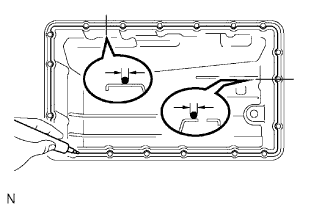

Apply FIPG to the oil pan as shown in the illustration.

Install the oil pan with the 19 bolts.

| 5. INSTALL TRANSMISSION OIL FILLER TUBE SUB-ASSEMBLY |

|

Coat a new O-ring with ATF, and install it to the oil filler tube.

Install the oil filler tube to the transmission with the 2 bolts.

Install the oil level gauge.

| 6. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 7. PERFORM INITIALIZATION |

Perform initialization (Click here).

| 8. ADD AUTOMATIC TRANSMISSION FLUID |

Add automatic transmission fluid (Click here).

| 9. INSPECT AUTOMATIC TRANSMISSION FLUID |

Inspect the automatic transmission fluid (Click here).