HOOD > ADJUSTMENT |

| 1. ADJUST HOOD SUB-ASSEMBLY |

|

Adjust the hood's position.

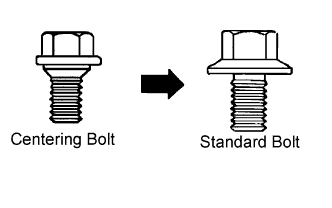

Loosen the hood's 4 hinge bolts.

Move the hood and adjust the clearance between the hood and front fender. Make sure that the clearance is within the standard range.

Tighten the hood's 4 hinge bolts after the adjustment.

|

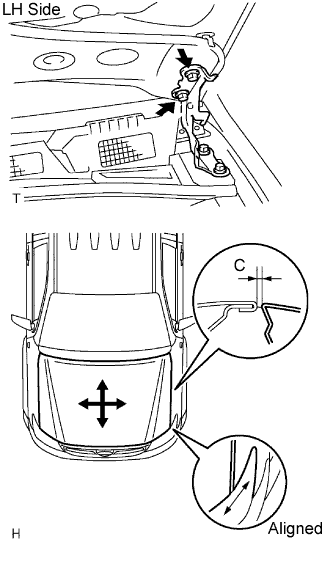

Adjust the cushion rubber so that the height of the hood and fender are aligned.

Raise or lower the hood's front end by turning the cushion rubber. Make sure that the clearance is within the standard range.

|

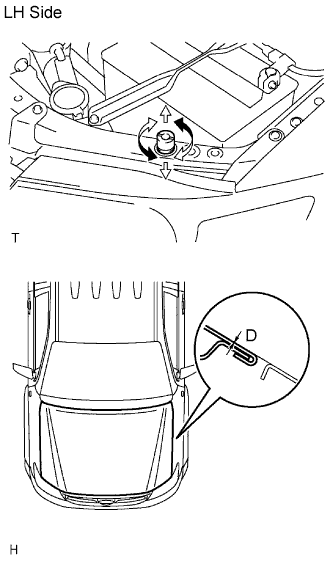

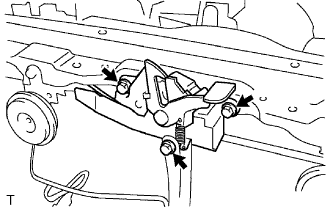

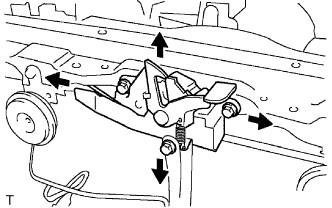

Adjust the hood lock.

Loosen the 3 bolts.

|

Adjust the hood lock position so that the striker can enter it smoothly.

Tighten the 3 bolts after the adjustment.