VANE PUMP (for TR Series Engine) > INSTALLATION |

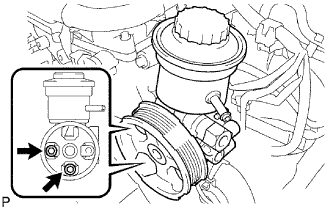

| 1. INSTALL VANE PUMP ASSEMBLY |

|

Install the vane pump with the 2 bolts.

|

Connect the connector to the oil pressure switch.

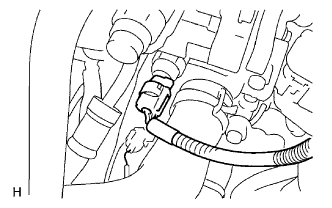

| 2. CONNECT PRESSURE FEED TUBE ASSEMBLY |

|

Install a new gasket and the pressure feed tube to the vane pump with the union bolt.

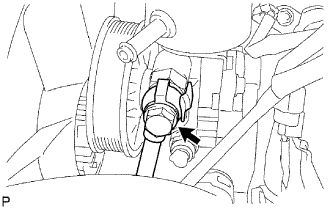

| 3. CONNECT RETURN HOSE |

|

Connect the hose with the clip.

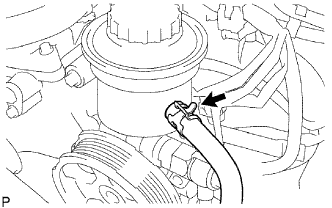

| 4. INSTALL FAN AND GENERATOR V BELT |

|

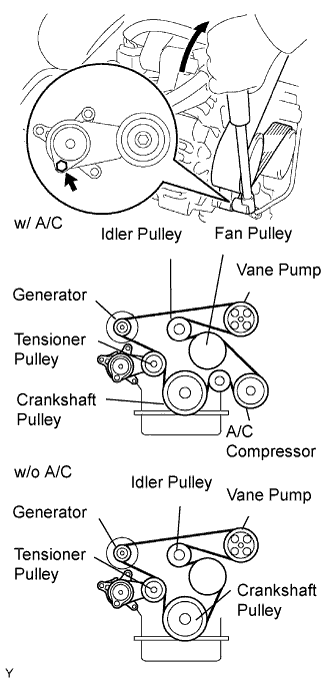

Install the drive belt to the pulleys except the drive belt tensioner pulley.

Use the hexagon-shaped part indicated by the arrow in the illustration to move the tensioner pulley downward and then install the drive belt to the tensioner pulley.

|

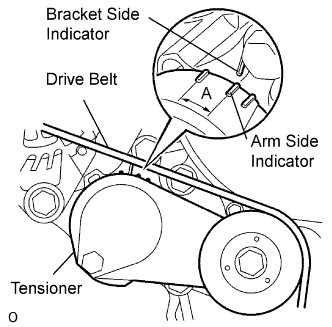

After a new belt has been installed, check that the tensioner indicator mark is within range A shown in the illustration.

| 5. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 6. ADD POWER STEERING FLUID |

| 7. BLEED AIR FROM POWER STEERING SYSTEM |

Check the fluid level.

Jack up the front of the vehicle and support it with stands.

Turn the steering wheel.

With the engine stopped, turn the steering wheel slowly from lock to lock several times.

Lower the vehicle.

Start the engine. Run the engine at idle for a few minutes.

Turn the steering wheel.

With the engine idling, turn the steering wheel to the left or right full lock position and hold it there for 2 to 3 seconds. Then turn the steering wheel to the opposite full lock position and hold it there for 2 to 3 seconds.

Repeat the step above several times.

Stop the engine.

|

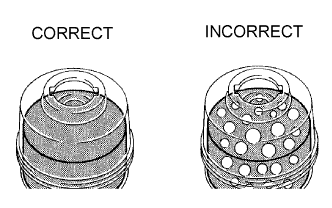

Check for foaming or emulsification. If the system has to be bled twice because of forming or emulsification, check for fluid leaks in the system.

Check the fluid level.

| 8. CHECK POWER STEERING FLUID LEVEL IN RESERVOIR |

| 9. CHECK FOR FLUID LEAKS |