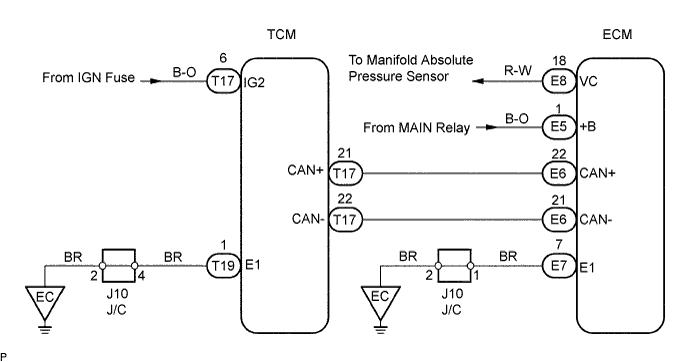

DTC U0001/A2 High Speed CAN Communication Bus |

| DTC No. | DTC Detection Condition | Trouble Area |

| U0001/A2 | No communication from TCM continues |

|

| 1.CHECK ECM (VC, +B VOLTAGE, E1 GROUND) |

|

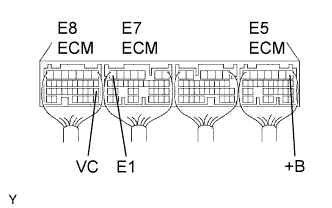

Measure the voltage and resistance of the ECM connectors.

| Tester Connection | Ignition Switch Position | Specified Condition |

| E5-1 (+B) - Body ground | ON | 9 to 14 V |

| E8-18 (VC) - Body ground | ON | 4.5 to 5.5 V |

| Tester Connection | Ignition Switch Position | Specified Condition |

| E7-7 (E1) - Body ground | - | 10 kΩ or higher |

|

| ||||

| OK | |

| 2.CHECK TCM (IG2 VOLTAGE, E1 GROUND) |

|

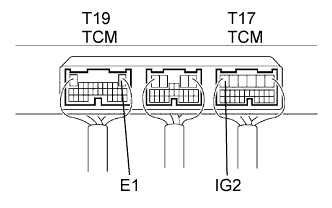

Measure the voltage and resistance of the TCM connectors.

| Tester Connection | Ignition Switch Position | Specified Condition |

| T17-6 (IG2) - Body ground | ON | 9 to 14 V |

| Tester Connection | Ignition Switch Position | Specified Condition |

| T19-1 (E1) - Body ground | - | 10 kΩ or higher |

|

| ||||

| OK | |

| 3.CHECK WIRE HARNESS (ECM - TCM) |

|

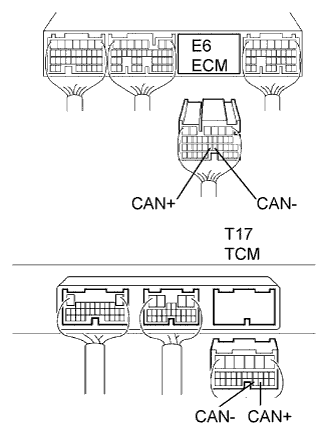

Disconnect the E6 ECM connector.

Disconnect the T17 TCM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| E6-22 (CAN+) - T17-21 (CAN+) | Below 1 Ω |

| E6-21 (CAN-) - T17-20 (CAN-) | Below 1 Ω |

| E6-22 (CAN+) or T17-21 (CAN+) - Body ground | 10 kΩ or higher |

| E6-21 (CAN-) or T17-20 (CAN-) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 4.CHECK IF DTC OUTPUT RECURS |

Clear the DTC (Click here).

Replace the TCM.

Start the engine.

Read the DTCs (Click here).

| Display (DTC Output) | Proceed to |

| U0001/A2 | A |

| No DTC | B |

|

| ||||

| A | ||

| ||