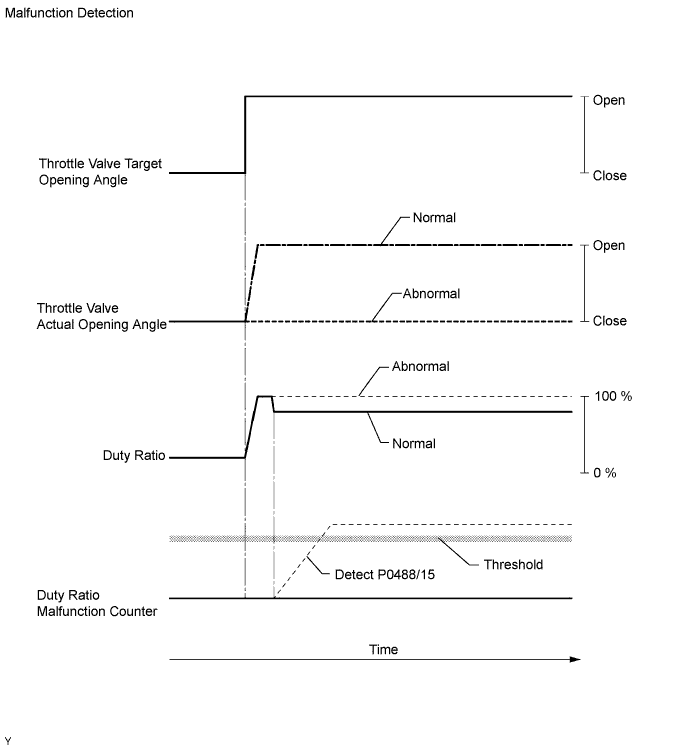

DTC P0488/15 Exhaust Gas Recirculation Throttle Position Control Range / Performance |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0488/15 |

|

|

| Condition | Throttle Valve Position |

| Moment when accelerator pedal is further depressed or released at 2,500 rpm | Opening angle varies smoothly |

| 1.CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P0448/15) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / DTC.

Read the DTCs (Click here).

| Display (DTC Output) | Proceed to |

| P0488/15 | A |

| P0488/15 and P0120/41, P0122/41 and/or P0123/41 | B |

|

| ||||

| A | |

| 2.CHECK IF DTC OUTPUT RECURS (DTC P0448/15 OUTPUT) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / DTC / Clear.

Clear the DTCs (Click here).

Start the engine and perform a quick engine acceleration from idling to 3,000 rpm 3 times.

Enter the following menus: Powertrain / Engine / DTC.

Read the DTCs (Click here).

| Display (DTC output) | Proceed to |

| P0488/15 | A |

| No output | B |

| Condition | Throttle Position |

| Moment when accelerator pedal is further depressed or released at 3,000 rpm | Opening angle varies smoothly |

|

| ||||

| A | |

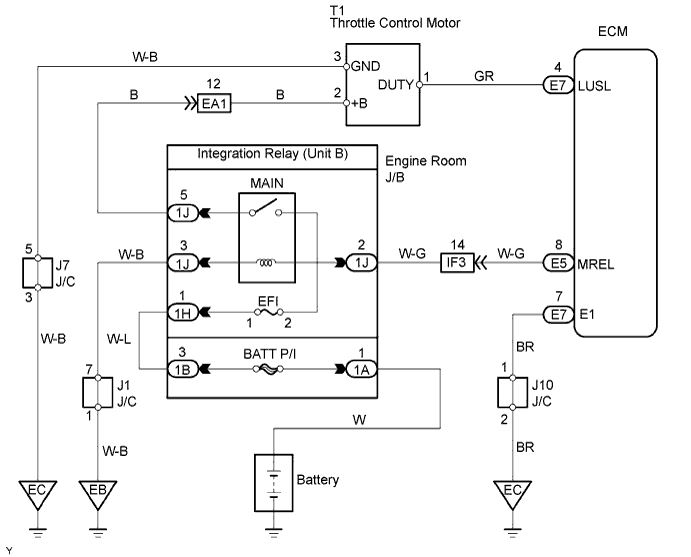

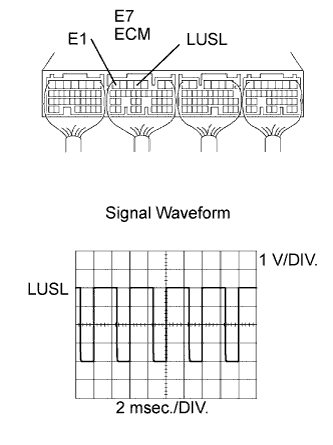

| 3.CHECK ECM (LUSL SIGNAL) |

|

While revving the engine, check the waveform of the ECM connector using an oscilloscope.

| Tester Connection | Specified Condition |

| E7-4 (LUSL) - E7-7 (E1) | Correct waveform is as shown |

| Tool Setting | 1 V/DIV., 2 msec./DIV. |

| Condition | Racing engine with warm engine |

|

| ||||

| OK | |

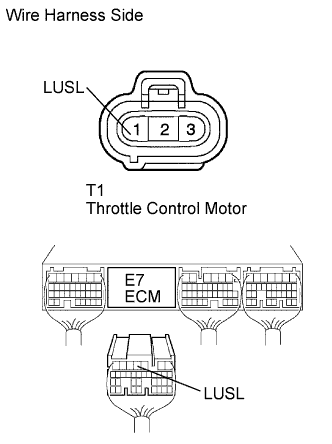

| 4.CHECK WIRE HARNESS (THROTTLE CONTROL MOTOR - ECM) |

|

Disconnect the T1 motor connector.

Disconnect the E7 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| T1-1 (DUTY) - E7-4 (LUSL) | Below 1 Ω |

| T1-1 (DUTY) or E7-4 (LUSL) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||