DTC P2120/19 Throttle / Pedal Position Sensor / Switch "D" Circuit |

DTC P2122/19 Throttle / Pedal Position Sensor / Switch "D" Circuit Low Input |

DTC P2123/19 Throttle / Pedal Position Sensor / Switch "D" Circuit High Input |

DTC P2125/19 Throttle / Pedal Position Sensor / Switch "E" Circuit |

DTC P2127/19 Throttle / Pedal Position Sensor / Switch "E" Circuit Low Input |

DTC P2128/19 Throttle / Pedal Position Sensor / Switch "E" Circuit High Input |

DTC P2138/19 Throttle / Pedal Position Sensor / Switch "D" / "E" Voltage Correlation |

| DTC No. | DTC Detection Condition (All of following are 1 trip detection logic) | Trouble Area |

| P2120/19 | Condition (a) continues for 0.5 sec. or more: (a) VPA is 0.2 V or less or VPA is 4.8 V or more |

|

| P2122/19 | VPA is 0.2 V or less for 0.5 sec. or more when VPA2 output indicates that accelerator pedal is opened |

|

| P2123/19 | Condition (a) continues for 2.0 sec. or more: (a) VPA is 4.8 V or more |

|

| P2125/19 | Condition (a) continues for 0.5 sec. or more: (a) (VPA2 is 0.5 V or less) or (VPA2 is 4.8 V or more) |

|

| P2127/19 | VPA2 is 0.5 V or less for 0.5 sec. or more when VPA output indicates that accelerator pedal is opened |

|

| P2128/19 | Conditions (a) and (b) continue for 2.0 sec. or more: (a) VPA2 is 4.8 V or more (b) VPA is 0.2 V or more and VPA is 3.45 V or less |

|

| P2138/19 | Condition (a) or (b) continues for 2.0 sec. or more: (a) Difference between VPA and VPA2 is 0.02 V or less (b) VPA is 0.2 V or less and VPA2 is 0.5 V or less |

|

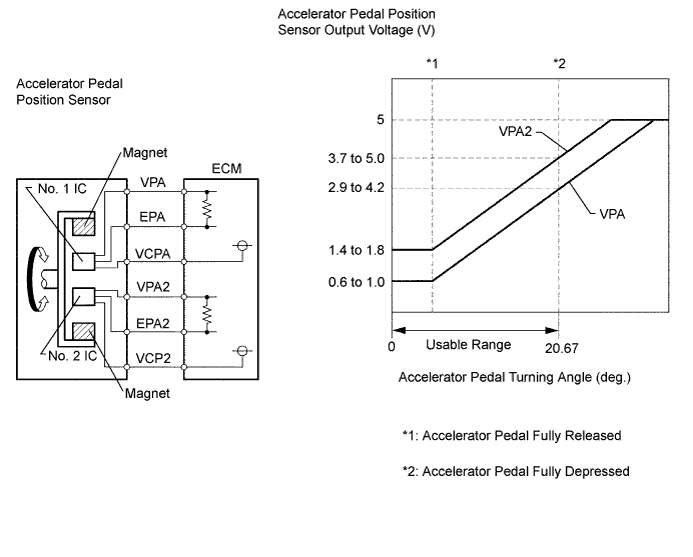

| - | Accelerator pedal position expressed as voltage output | |||

| - | Accelerator pedal released | Accelerator pedal depressed | ||

| Trouble Area | Accelerator Position No.1 | Accelerator Position No. 2 | Accelerator Position No. 1 | Accelerator Position No. 2 |

| VCP circuit open | 0 to 0.2 V | 0 to 0.2 V | 0 to 0.2 V | 0 to 0.2 V |

| VPA circuit open or ground short | 0 to 0.2 V | 1.4 to 1.8 V | 0 to 0.2 V | 3.7 to 5.0 V |

| VPA2 circuit open or ground short | 0.6 to 1.0 V | 0 to 0.2 V | 2.9 to 4.2 V | 0 to 0.2 V |

| EP circuit open | 4.5 to 5.0 V | 4.5 to 5.0 V | 4.5 to 5.0 V | 4.5 to 5.0 V |

| 1.READ DATA LIST (ACCEL POSITION 1, ACCEL POSITION 2) |

|

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / Data List / Accel Position 1 and Accel Position 2.

Read the values.

| Accelerator Pedal | Accel Position 1 | Accel Position 2 |

| Released | 0.6 to 1.0 V | 1.4 to 1.8 V |

| Depressed | 2.9 to 4.2 V | 3.7 to 5.0 V |

|

| ||||

| NG | |

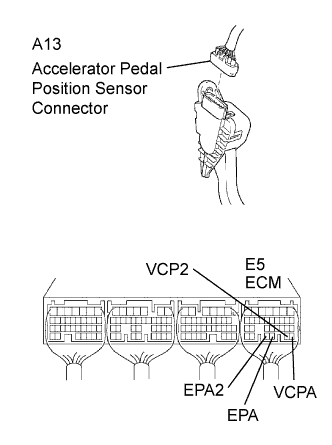

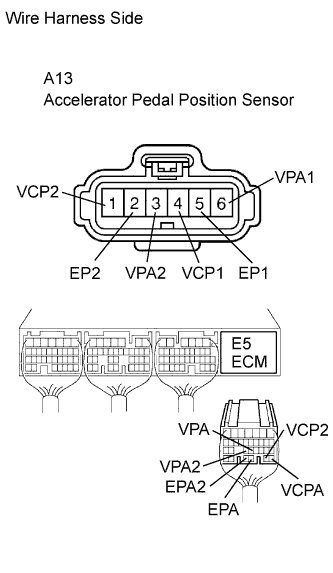

| 2.CHECK WIRE HARNESS (ECM - ACCELERATOR PEDAL POSITION SENSOR) |

|

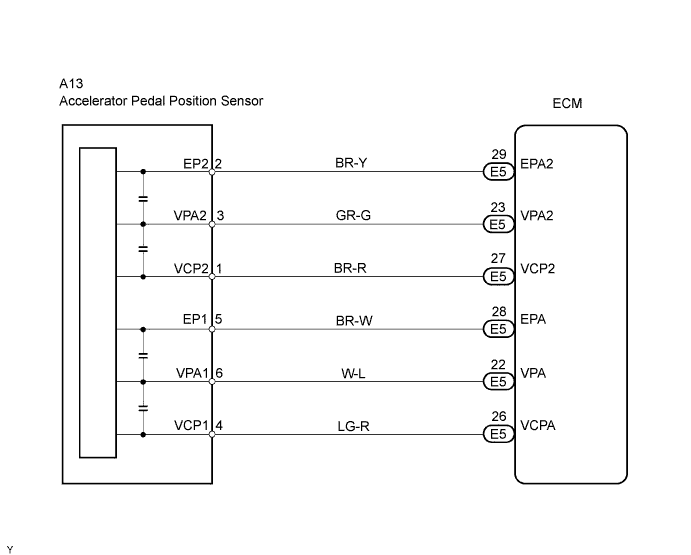

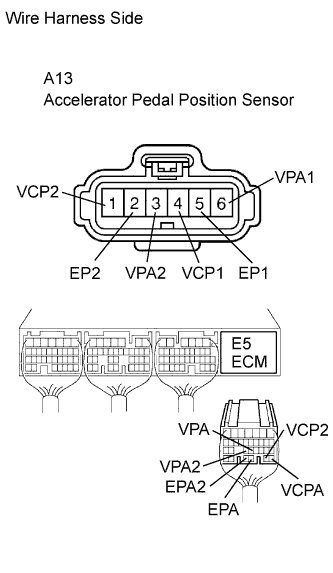

Disconnect the A13 sensor connector.

Disconnect the E5 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| A13-1 (VCP2) - E5-27 (VCP2) A13-2 (EP2) - E5-29 (EPA2) A13-3 (VPA2) - E5-23 (VPA2) A13-4 (VCP1) - E5-26 (VCPA) A13-5 (EP1) - E5-28 (EPA) A13-6 (VPA1) - E5-22 (VPA) | Below 1 Ω |

| A13-1 (VCP2) or E5-27 (VCP2) - Body ground A13-2 (EP2) or E5-29 (EPA2) - Body ground A13-3 (VPA2) or E5-23 (VPA2) - Body ground A13-4 (VCP1) or E5-26 (VCPA) - Body ground A13-5 (EP1) or E5-28 (EPA) - Body ground A13-6 (VPA1) or E5-22 (VPA) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

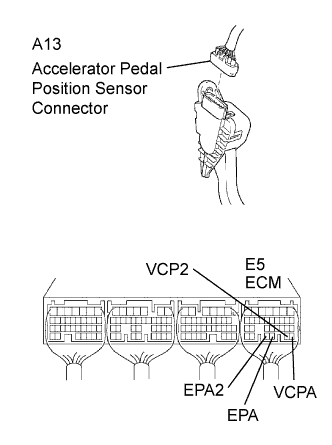

| 3.CHECK ECM (VCPA, VCP2 VOLTAGE) |

|

Disconnect the A13 sensor connector.

Turn the ignition switch ON.

Measure the voltage of the ECM connector.

| Tester Connection | Specified Condition |

| E5-26 (VCPA) - E5-28 (EPA) E5-27 (VCP2) - E5-29 (EPA2) | 4.5 to 5.0 V |

|

| ||||

| OK | |

| 4.REPLACE ACCELERATOR PEDAL ROD ASSEMBLY |

| NEXT | |

| 5.READ OUTPUT DTC (ACCELERATOR PEDAL POSITION SENSOR DTC IS OUTPUT AGAIN) |

Clear the DTC (Click here).

Start the engine.

Drive the engine at idle for 15 seconds or more.

Read the DTC (Click here).

| Display (DTC output) | Proceed to |

| P2120/19, P2122/19, P2123/19, P2125/19, P2127/19, P2128/19 or P2138/19 is output again | A |

| P2120/19, P2122/19, P2123/19, P2125/19, P2127/19, P2128/19 or P2138/19 is not output | B |

|

| ||||

| A | ||

| ||

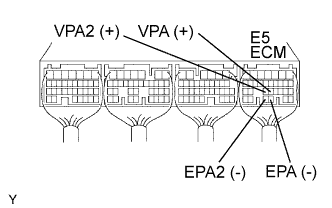

| 1.CHECK ECM (VPA, VPA2 VOLTAGE) |

|

Turn the ignition switch ON.

Measure the voltage of the ECM connector.

| Tester Condition | Accelerator Pedal Condition | Specified Condition |

| E5-22 (VPA) - E5-28 (EPA) | Released | 0.6 to 1.0 V |

| E5-22 (VPA) - E5-28 (EPA) | Depressed | 2.9 to 4.2 V |

| E5-23 (VPA2) - E5-29 (EPA2) | Released | 1.4 to 1.8 V |

| E5-23 (VPA2) - E5-29 (EPA2) | Depressed | 3.7 to 5.0 V |

|

| ||||

| NG | |

| 2.CHECK WIRE HARNESS (ECM - ACCELERATOR PEDAL POSITION SENSOR) |

|

Disconnect the A13 sensor connector.

Disconnect the E5 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| A13-1 (VCP2) - E5-27 (VCP2) A13-2 (EP2) - E5-29 (EPA2) A13-3 (VPA2) - E5-23 (VPA2) A13-4 (VCP1) - E5-26 (VCPA) A13-5 (EP1) - E5-28 (EPA) A13-6 (VPA1) - E5-22 (VPA) | Below 1 Ω |

| A13-1 (VCP2) or E5-27 (VCP2) - Body ground A13-2 (EP2) or E5-29 (EPA2) - Body ground A13-3 (VPA2) or E5-23 (VPA2) - Body ground A13-4 (VCP1) or E5-26 (VCPA) - Body ground A13-5 (EP1) or E5-28 (EPA) - Body ground A13-6 (VPA1) or E5-22 (VPA) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 3.CHECK ECM (VCPA, VCP2 VOLTAGE) |

|

Disconnect the A13 sensor connector.

Turn the ignition switch ON.

Measure the voltage of the ECM connector.

| Tester Connection | Specified Condition |

| E5-26 (VCPA) - E5-28 (EPA) E5-27 (VCP2) - E5-29 (EPA2) | 4.5 to 5.0 V |

|

| ||||

| OK | |

| 4.REPLACE ACCELERATOR PEDAL ROD ASSEMBLY |

| NEXT | |

| 5.READ OUTPUT DTC (ACCELERATOR PEDAL POSITION SENSOR DTC IS OUTPUT AGAIN) |

Clear the DTC (Click here).

Start the engine.

Drive the engine at idle for 15 seconds or more.

Read the DTC (Click here).

| Display (DTC output) | Proceed to |

| P2120/19, P2122/19, P2123/19, P2125/19, P2127/19, P2128/19 or P2138/19 is output again | A |

| P2120/19, P2122/19, P2123/19, P2125/19, P2127/19, P2128/19 or P2138/19 is not output | B |

|

| ||||

| A | ||

| ||