COMPRESSOR AND PULLEY (for 2KD-FTV) > INSTALLATION |

| 1. ADJUST COMPRESSOR OIL |

When replacing the compressor with a new one after gradually releasing the refrigerant gas from the service valve, drain the following amount of oil from the new compressor before installation.

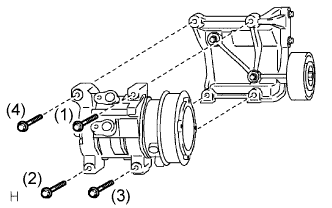

| 2. INSTALL COOLER COMPRESSOR ASSEMBLY |

|

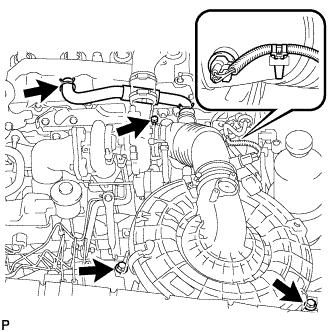

Install the compressor with the 4 bolts and tighten the bolts in the order shown in the illustration.

Connect the connector.

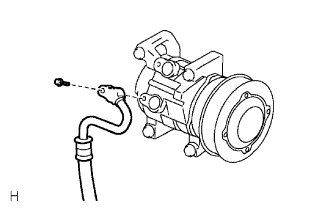

| 3. INSTALL NO. 1 COOLER REFRIGERANT DISCHARGE HOSE |

|

Remove the vinyl tape attached to the hose.

Sufficiently apply compressor oil to a new O-ring and the fitting surface of the compressor.

Install the O-ring on the discharge hose.

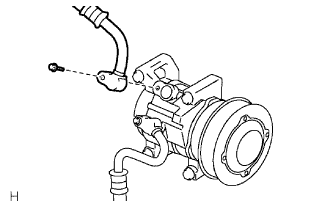

| 4. INSTALL SUCTION HOSE SUB-ASSEMBLY |

|

Remove the vinyl tape attached to the hose.

Sufficiently apply compressor oil to a new O-ring and the fitting surface of the compressor.

Install the O-ring on the suction hose.

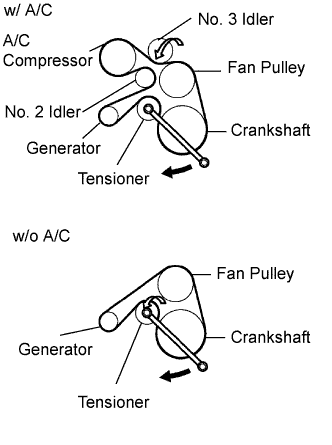

| 5. INSTALL DRIVE BELT |

|

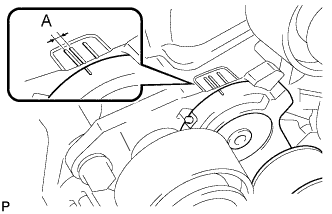

Use the pulley set bolt of the tensioner to rotate the tensioner pulley clockwise, and then install the V belt.

|

Make sure that the indicator mark of the tensioner is within range A, as shown in the illustration.

| 6. INSTALL AIR CLEANER ASSEMBLY |

|

Connect the air cleaner hose.

Install the air cleaner with the 2 bolts.

Tighten the clamp.

Install the clamp and connect the IAT connector.

Connect the ventilation hose.

Slide the clamp to the connection of the hose.

| 7. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 8. PERFORM INITIALIZATION |

Perform initialization (Click here).

| 9. CHARGE REFRIGERANT |

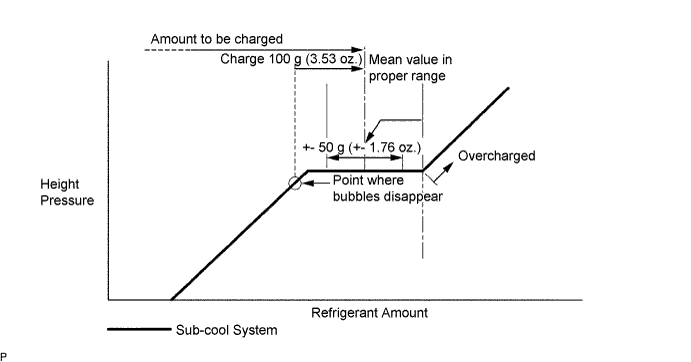

Perform vacuum purging using a vacuum pump.

Charge refrigerant HFC-134a (R134a).

| 10. WARM UP ENGINE |

Warm up the engine at less than 1,850 rpm for 2 minutes or more after charging refrigerant.

| 11. CHECK FOR LEAKAGE OF REFRIGERANT |

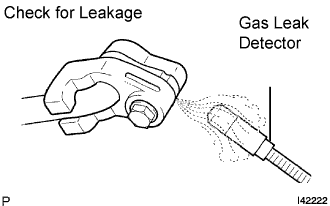

After recharging the refrigerant gas, check for refrigerant gas leakage using a halogen leak detector.

Perform the operation under these conditions:

|

Using a gas leak detector, check the refrigerant line for leakage.

If a gas leak is not detected on the drain hose, remove the blower motor control (blower resistor) from the cooling unit. Insert the gas leak detector sensor into the unit and perform the test.

Disconnect the connector and leave the pressure switch on for approximately 20 minutes. Bring the gas leak detector close to the pressure switch and perform the test.