OUTPUT SHAFT > INSTALLATION |

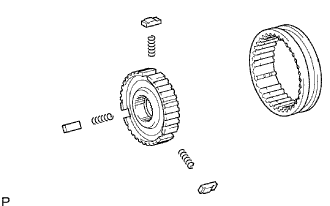

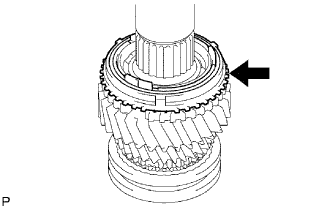

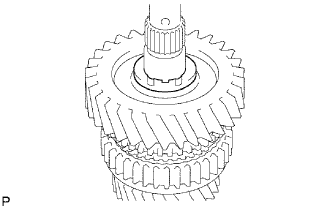

| 1. INSTALL NO. 2 TRANSMISSION HUB SLEEVE |

|

Install the 3 No. 2 synchromesh shifting key springs and 3 synchromesh shifting keys to the No. 2 clutch hub.

Apply gear oil to the sliding part of the No. 2 hub sleeve, and install it to the No. 2 clutch hub.

| 2. INSTALL 3RD GEAR NEEDLE ROLLER BEARING |

|

Apply gear oil to the needle roller bearing, and install it to the output shaft.

| 3. INSTALL 3RD GEAR |

|

Apply gear oil to the 3rd gear, and install it to the output shaft.

| 4. INSTALL NO. 2 SYNCHRONIZER RING (FOR 3RD GEAR) |

|

Apply gear oil to the No. 2 synchronizer ring, and install it to the 3rd gear.

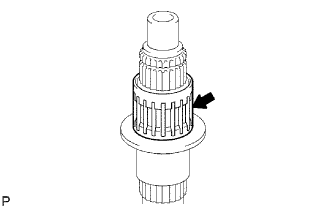

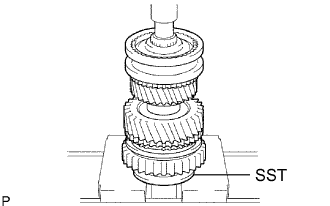

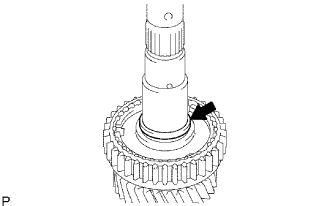

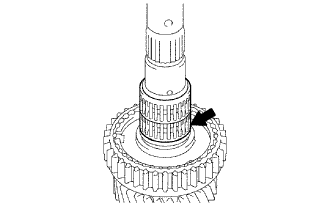

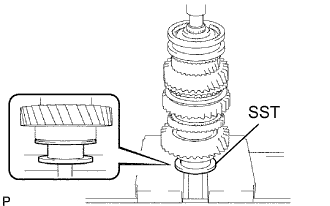

| 5. INSTALL NO. 2 TRANSMISSION CLUTCH HUB |

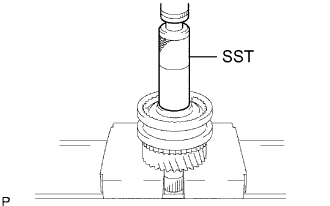

|

Using SST and a press, press in the No. 2 clutch hub to the output shaft.

Select a snap ring that makes the clearance between the No. 2 clutch hub and snap ring to be within the specification.

| Mark | Thickness |

| A | 1.80 to 1.85 mm (0.0709 to 0.0728 in.) |

| B | 1.85 to 1.90 mm (0.0728 to 0.0748 in.) |

| C | 1.90 to 1.95 mm (0.0748 to 0.0768 in.) |

| D | 1.95 to 2.00 mm (0.0768 to 0.0787 in.) |

| E | 2.00 to 2.05 mm (0.0787 to 0.0807 in.) |

| F | 2.05 to 2.10 mm (0.0807 to 0.0827 in.) |

| G | 2.10 to 2.15 mm (0.0827 to 0.0846 in.) |

|

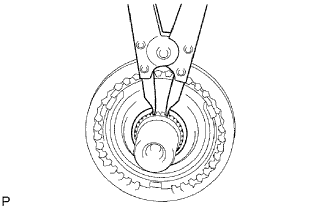

Using a snap ring expander, install the snap ring.

| 6. INSTALL 2ND GEAR NEEDLE ROLLER BEARING |

|

Apply gear oil to the needle roller bearing, and install it to the output shaft.

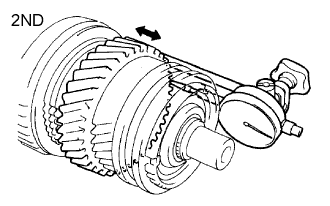

| 7. INSTALL 2ND GEAR |

|

Apply gear oil to the 2nd gear, and install it to the output shaft.

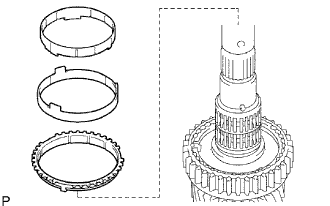

| 8. INSTALL NO. 1 SYNCHRONIZER RING SET (FOR 2ND GEAR) |

|

Apply gear oil to the No. 1 synchronizer ring set, and install it to the 2nd gear.

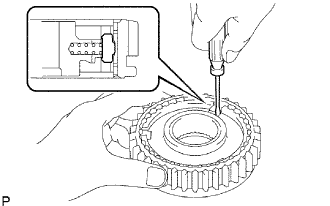

| 9. INSTALL REVERSE GEAR |

|

Using a screwdriver, install the 3 synchromesh shifting key springs and 3 No. 1 synchromesh shifting keys to the No. 1 clutch hub.

Apply gear oil to the reverse gear, and install it to the No. 1 clutch hub.

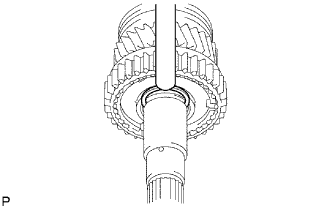

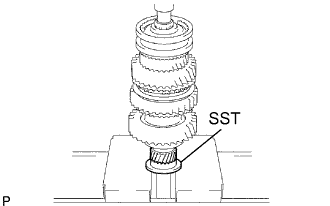

| 10. INSTALL NO. 1 TRANSMISSION CLUTCH HUB |

|

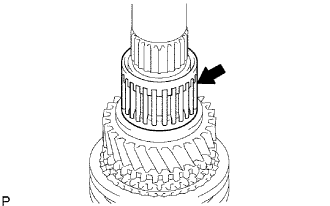

Using SST and a press, press in the No. 1 clutch hub to the output shaft.

Select a snap ring that makes the thrust clearance between the No. 1 clutch hub and snap ring to be within the specification.

| Mark | Thickness |

| A | 2.30 to 2.35 mm (0.0906 to 0.0925 in.) |

| B | 2.35 to 2.40 mm (0.0925 to 0.0945 in.) |

| C | 2.40 to 2.45 mm (0.0945 to 0.0965 in.) |

| D | 2.45 to 2.50 mm (0.0965 to 0.0984 in.) |

| E | 2.50 to 2.55 mm (0.0984 to 0.1004 in.) |

| F | 2.55 to 2.60 mm (0.1004 to 0.1024 in.) |

| G | 2.60 to 2.65 mm (0.1024 to 0.1043 in.) |

|

Using a brass bar and a hammer, tap in the snap ring.

| 11. INSTALL 1ST GEAR BEARING SPACER |

|

Apply gear oil to the bearing spacer, and install it to the output shaft.

| 12. INSTALL 1ST GEAR NEEDLE ROLLER BEARING |

|

Apply gear oil to the needle roller bearing, and install it to the output shaft.

| 13. INSTALL 1ST GEAR THRUST WASHER PIN |

Install the thrust washer pin to the output shaft.

| 14. INSTALL NO. 1 SYNCHRONIZER RING SET (FOR 1ST GEAR) |

|

Apply gear oil to the No. 1 synchronizer ring set, and install them to the output shaft.

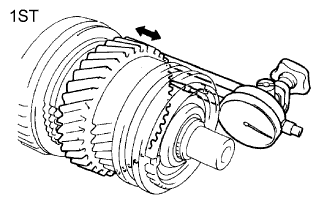

| 15. INSTALL 1ST GEAR |

|

Apply gear oil to the 1st gear, and install it to the output shaft.

| 16. INSTALL 1ST GEAR THRUST WASHER |

|

Apply gear oil to the thrust washer, and install it to the output shaft.

| 17. INSTALL OUTPUT SHAFT CENTER BEARING |

|

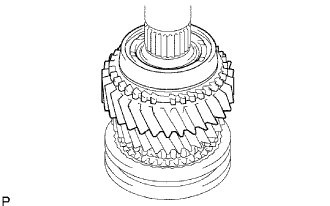

Using SST and a press, press in a new center bearing to the output shaft.

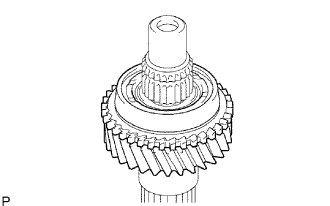

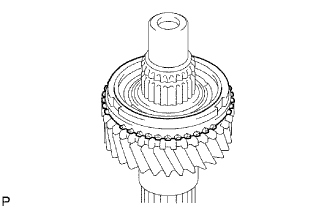

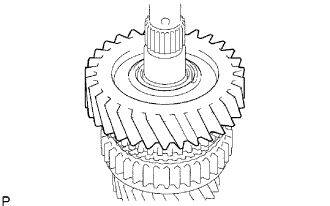

| 18. INSTALL 5TH GEAR |

|

Using SST and a press, press in the 5th gear to the output shaft.

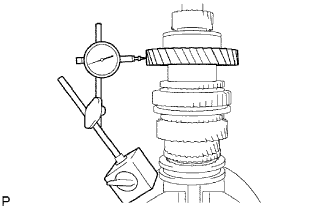

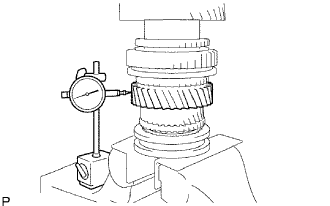

| 19. INSPECT 1ST GEAR THRUST CLEARANCE |

|

Using a dial indicator, measure the thrust clearance.

| 20. INSPECT 2ND GEAR THRUST CLEARANCE |

|

Using a dial indicator, measure the thrust clearance.

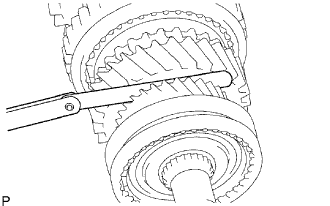

| 21. INSPECT 3RD GEAR THRUST CLEARANCE |

|

Using a feeler gauge, measure the thrust clearance.

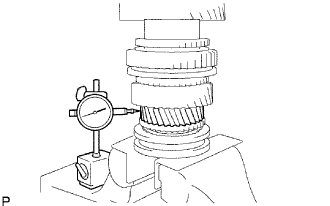

| 22. INSPECT 1ST GEAR RADIAL CLEARANCE |

|

Using a dial indicator, measure the radial clearance.

| 23. INSPECT 2ND GEAR RADIAL CLEARANCE |

|

Using a dial indicator, measure the radial clearance.

| 24. INSPECT 3RD GEAR RADIAL CLEARANCE |

|

Using a dial indicator, measure the radial clearance.