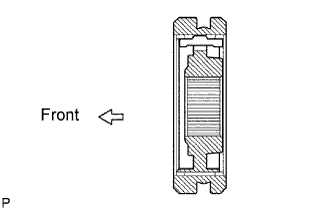

OUTPUT SHAFT > INSTALLATION |

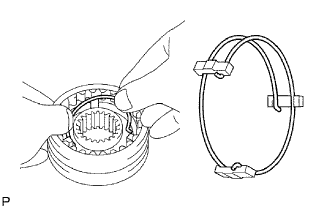

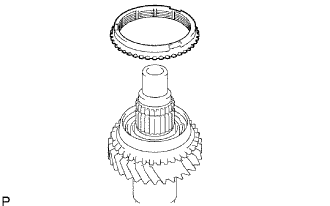

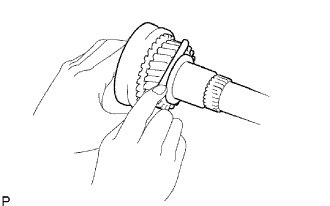

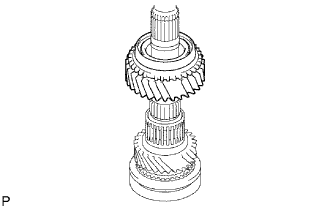

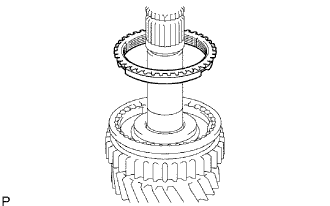

| 1. INSTALL NO. 2 TRANSMISSION CLUTCH HUB |

|

Coat the hub sleeve with gear oil, and install it to the clutch hub.

|

Install the 3 synchromesh shifting keys to the clutch hub with the 2 synchromesh shifting key springs.

| 2. INSTALL 3RD GEAR NEEDLE ROLLER BEARING |

|

Coat the needle roller bearing with gear oil, and install it to the output shaft.

| 3. INSTALL 3RD GEAR |

|

Coat the 3rd gear with gear oil, and install it to the output shaft.

| 4. INSTALL NO. 2 SYNCHRONIZER RING |

|

Coat the synchronizer ring with gear oil, and install it to the 3rd gear.

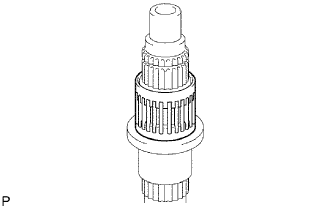

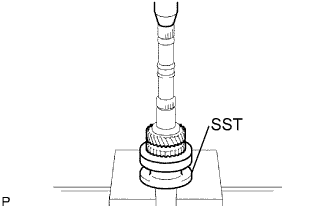

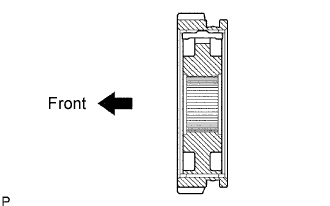

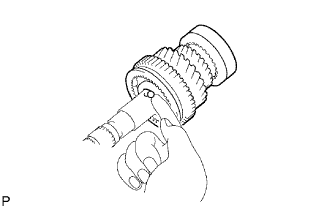

| 5. INSTALL NO. 2 TRANSMISSION CLUTCH HUB |

|

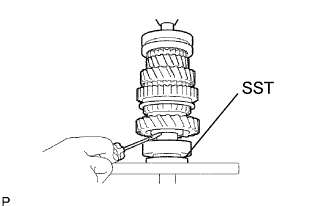

Using SST and a press, press in the No. 2 clutch hub to the output shaft.

|

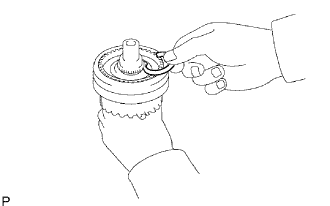

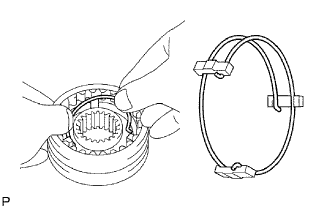

Select a clutch hub shaft snap ring that will allow minimal axial play.

| Mark | Thickness |

| C-1 | 1.75 to 1.80 mm (0.0689 to 0.0709 in.) |

| D | 1.80 to 1.85 mm (0.0709 to 0.0728 in.) |

| D-1 | 1.85 to 1.90 mm (0.0728 to 0.0748 in.) |

| E | 1.90 to 1.95 mm (0.0748 to 0.0768 in.) |

| E-1 | 1.95 to 2.00 mm (0.0768 to 0.0787 in.) |

| F | 2.00 to 2.05 mm (0.0787 to 0.0807 in.) |

| F-1 | 2.05 to 2.10 mm (0.0807 to 0.0827 in.) |

|

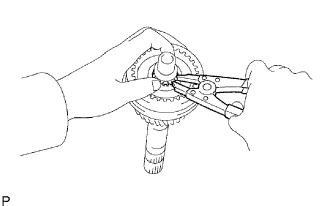

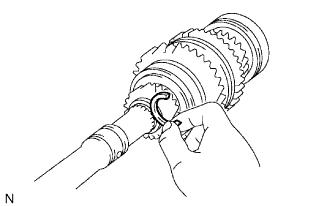

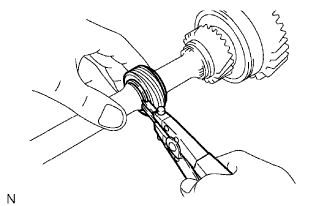

Using a snap ring expander, install the snap ring.

| 6. INSPECT 3RD GEAR THRUST CLEARANCE |

|

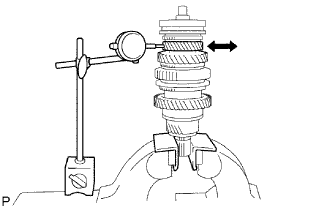

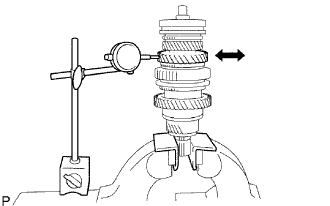

Using a feeler gauge, measure the thrust clearance.

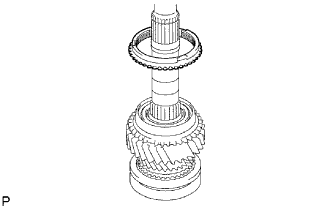

| 7. INSTALL NO. 1 TRANSMISSION CLUTCH HUB |

|

Coat the reverse gear with gear oil, and install it to the clutch hub.

|

Install 3 synchromesh shifting keys to the clutch hub with the 2 synchromesh shifting key springs.

| 8. INSTALL 2ND GEAR NEEDLE ROLLER BEARING |

|

Coat the needle roller bearing with gear oil, and install it to the output shaft.

| 9. INSTALL 2ND GEAR |

|

Coat the 2nd gear with gear oil, and install it to the output shaft.

| 10. INSTALL NO. 1 SYNCHRONIZER RING (FOR 2ND GEAR) |

|

Coat the No. 1 synchronizer ring with gear oil, and install it to the 2nd gear.

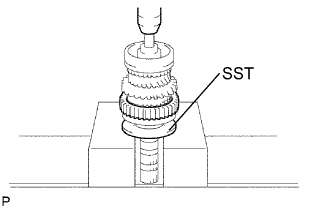

| 11. INSTALL NO. 1 TRANSMISSION CLUTCH HUB |

|

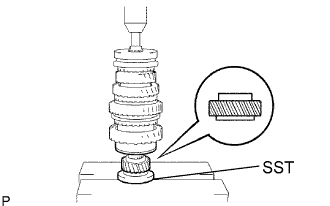

Using SST and a press, press in the clutch hub to the output shaft.

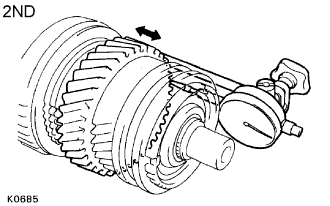

| 12. INSPECT 2ND GEAR THRUST CLEARANCE |

|

Using a dial indicator, measure the thrust clearance.

| 13. INSTALL NO. 1 SYNCHRONIZER RING (FOR 1ST GEAR) |

|

Coat the synchronizer ring with gear oil, and install it to the No. 1 clutch hub.

| 14. INSTALL 1ST GEAR BEARING INNER RACE LOCK BALL |

|

Coat the lock ball with gear oil, and install it to the output shaft.

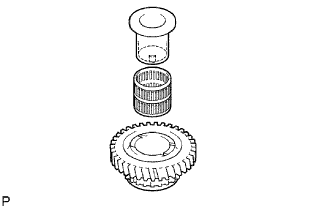

| 15. INSTALL 1ST GEAR BEARING INNER RACE |

|

Coat the needle roller bearing with gear oil.

Install the inner race and the needle roller bearing to 1st gear.

| 16. INSTALL 1ST GEAR |

|

Coat the 1st gear with gear oil, and install it to the output shaft.

| 17. INSTALL OUTPUT SHAFT CENTER BEARING |

|

Using SST and a press, press in the center bearing to the output shaft.

| 18. INSPECT 1ST GEAR THRUST CLEARANCE |

|

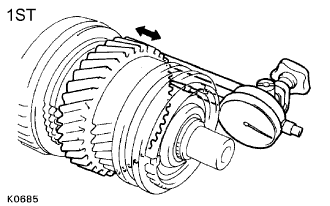

Using a dial indicator, measure the thrust clearance.

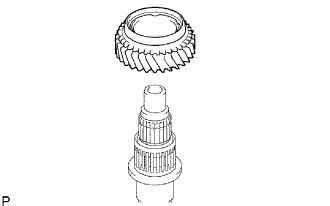

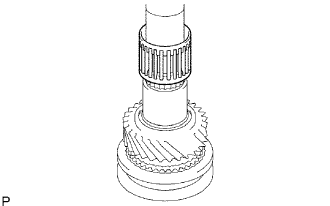

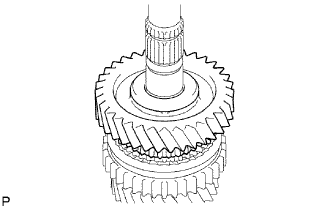

| 19. INSTALL 5TH GEAR |

|

Using SST and a press, press in the 5th gear to the output shaft.

|

Select a snap ting that will allow minimal axial play.

| Mark | Thickness |

| A | 2.67 to 2.72 mm (0.1051 to 0.1071 in.) |

| B | 2.73 to 2.78 mm (0.1075 to 0.1094 in.) |

| C | 2.79 to 2.84 mm (0.1098 to 0.1118 in.) |

| D | 2.85 to 2.90 mm (0.1122 to 0.1141 in.) |

| E | 2.91 to 2.96 mm (0.1146 to 0.1165 in.) |

| F | 2.97 to 3.02 mm (0.1169 to 0.1189 in.) |

| G | 3.03 to 3.08 mm (0.1193 to 0.1213 in.) |

| H | 3.09 to 3.14 mm (0.1217 to 0.1236 in.) |

| J | 3.15 to 3.20 mm (0.1240 to 0.1260 in.) |

| K | 3.21 to 3.26 mm (0.1264 to 0.1283 in.) |

| L | 3.27 to 3.32 mm (0.1287 to 0.1307 in.) |

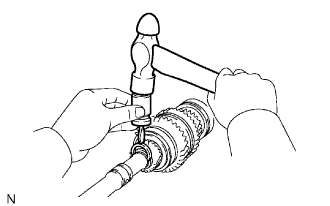

|

Using a screwdriver and hammer, tap in the snap ring.

| 20. INSTALL SPEEDOMETER DRIVE GEAR |

|

Using a snap ring expander, install the snap ring.

Install the ball.

Install the drive gear.

Using a snap ring expander, install the snap ring.

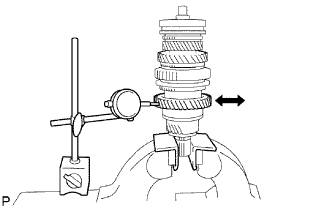

| 21. INSPECT 3RD GEAR RADIAL CLEARANCE |

|

Using a dial indicator, measure the radial clearance.

| 22. INSPECT 2ND GEAR RADIAL CLEARANCE |

|

Using a dial indicator, measure the radial clearance.

| 23. INSPECT 1ST GEAR RADIAL CLEARANCE |

|

Using a dial indicator, measure the radial clearance.