INPUT SHAFT > REMOVAL |

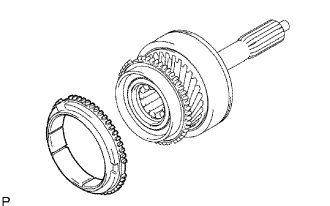

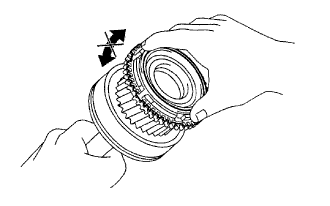

| 1. REMOVE NO. 2 SYNCHRONIZER RING |

|

Remove the synchronizer ring.

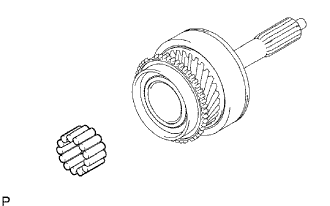

| 2. REMOVE INPUT SHAFT BEARING |

|

Remove the 13 input shaft bearings.

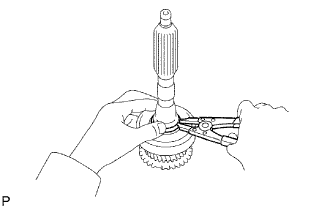

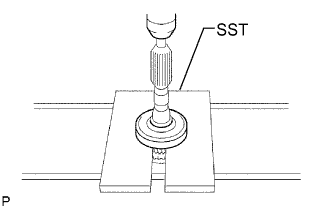

| 3. REMOVE INPUT SHAFT FRONT BEARING |

|

Using a snap ring expander, remove the snap ring.

|

Using SST and a press, press out the front bearing.

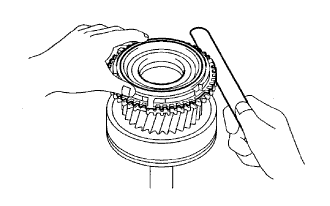

| 4. INSPECT NO. 2 SYNCHRONIZER RING |

|

Coat the input shaft cone with gear oil. Check the braking effect of the No. 2 synchronizer ring. Fit the ring to the shaft con. Apply pressure to the ring and attempt to turn it both directions. Check that the ring locks.

Check the braking effect of the No. 2 synchronizer ring again.

|

Using a feeler gauge, measure the clearance between the No. 2 synchronizer ring back and the input shaft spline end.