DIFFERENTIAL VACUUM ACTUATOR > REPLACEMENT |

| 1. REMOVE FRONT SIDE MEMBER TO FRONT SUSPENSION CROSSMEMBER BRACE |

| 2. REMOVE NO. 1 ENGINE UNDER COVER |

| 3. REMOVE NO. 2 ENGINE UNDER COVER |

| 4. DRAIN DIFFERENTIAL OIL |

| 5. REMOVE DIFFERENTIAL VACUUM ACTUATOR ASSEMBLY |

|

Remove the bolt and disconnect the differential breather tube bracket.

Support the differential with a jack.

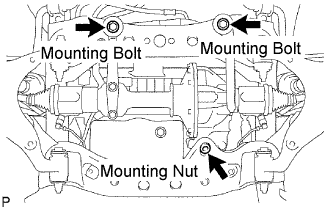

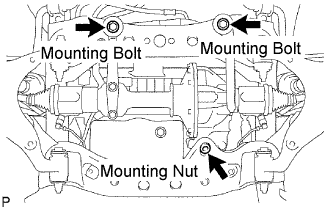

Remove the differential mounting nut No. 1.

Remove the 2 mounting bolts and 2 nuts.

Disconnect the actuator hose and connector.

Lower the jack.

|

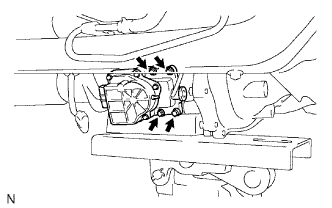

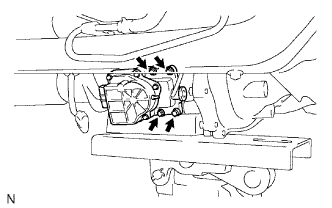

Remove the 4 bolts and vacuum actuator.

| 6. INSTALL DIFFERENTIAL VACUUM ACTUATOR ASSEMBLY |

|

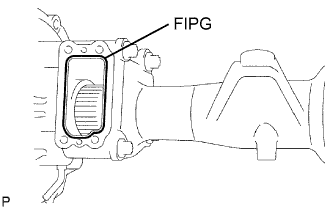

Remove any old FIPG material.

Using gasoline or alcohol, clean any residual FIPG material on the contact surfaces.

Apply FIPG to the differential tube, as shown in the illustration.

|

Clean the threads of the 4 bolts and retainer bolt holes with toluene or trichloroethylene.

Apply adhesive to 2 or 3 threads at the tip of the bolt.

Install the differential vacuum actuator to the differential tube with the 4 bolts.

|

Connect the actuator hose and connector.

Support the differential with a jack.

Install the 2 front mounting bolts and 2 nuts.

Install the differential mounting nuts No. 1.

Install the differential breather tube bracket with the bolt.

| 7. REFILL DIFFERENTIAL OIL |

Refill differential oil (Click here).

| 8. CHECK FOR DIFFERENTIAL OIL LEAKAGE |

|

Stop the vehicle on a level surface.

Remove the differential filler plug and gasket.

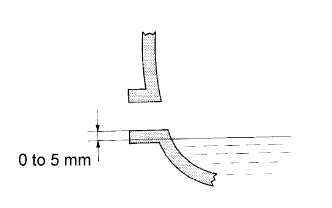

Check that the oil level is between 0 to 5 mm (0 to 0.20 in.) from the bottom lip of the differential filler plug hole.

| Temperature | Viscosity |

| Above -18°C (0°F) | SAE 90 |

| Below -18°C (0°F) | SAE 80W or 80W - 90 |

Check for oil leakage when the oil level is low.

Install the differential filler plug with a new gasket.

| 9. INSTALL NO. 2 ENGINE UNDER COVER |

| 10. INSTALL NO. 1 ENGINE UNDER COVER |

| 11. INSTALL FRONT SIDE MEMBER TO FRONT SUSPENSION CROSSMEMBER BRACE |