REAR DIFFERENTIAL CARRIER ASSEMBLY > DISASSEMBLY |

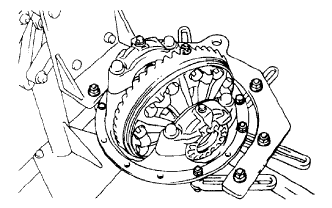

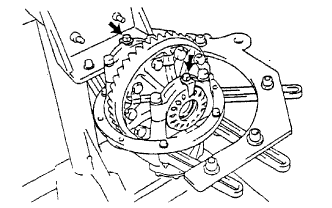

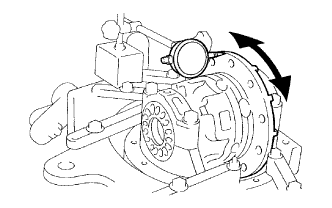

| 1. FIX REAR DIFFERENTIAL CARRIER ASSEMBLY |

|

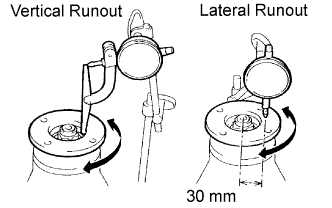

| 2. INSPECT RUNOUT OF REAR DRIVE PINION COMPANION FLANGE SUB-ASSEMBLY REAR |

|

Using a dial indicator, measure the runout of the companion flange vertically and laterally.

| Runout | Maximum |

| Vertical runout | 0.10 mm (0.0039 in.) |

| Lateral runout | 0.10 mm (0.0039 in.) |

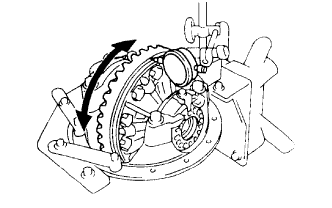

| 3. INSPECT RUNOUT OF DIFFERENTIAL RING GEAR |

|

Using a dial indicator, check the runout of the ring gear.

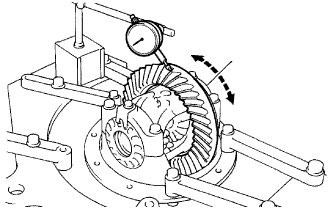

| 4. INSPECT DIFFERENTIAL RING GEAR BACKLASH |

|

Using a dial indicator, check the backlash of the ring gear.

| 5. INSPECT DIFFERENTIAL DRIVE PINION PRELOAD |

|

Using a torque wrench, measure the preload of backlash between the drive pinion and ring gear.

| 6. INSPECT TOTAL PRELOAD |

|

Using a torque wrench, measure the preload with the teeth of the drive pinion and ring gear in contact.

Using a torque wrench, measure the total preload.

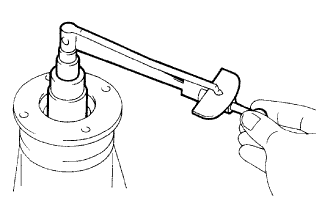

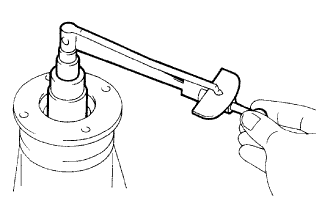

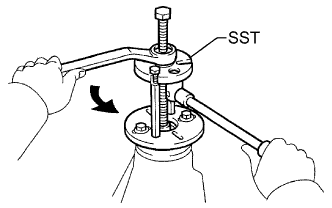

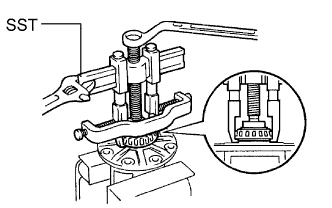

| 7. REMOVE REAR DRIVE PINION NUT |

|

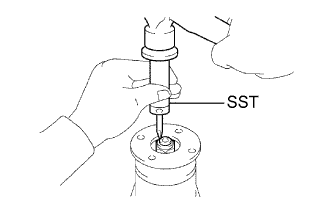

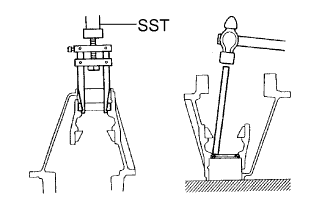

Using SST and a hammer, loosen the staked part of the nut.

|

Using SST to hold the companion flange in place, remove the nut.

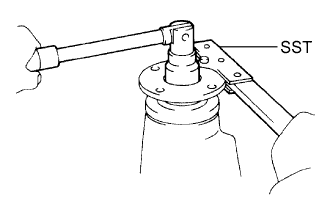

| 8. REMOVE REAR DRIVE PINION COMPANION FLANGE SUB-ASSEMBLY |

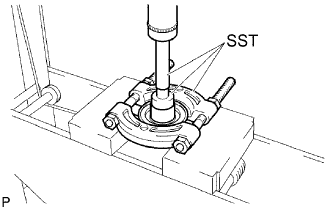

|

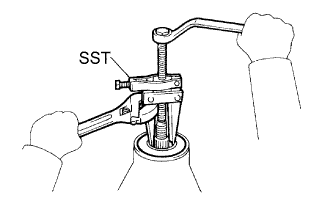

Using SST, remove the companion flange.

| 9. REMOVE REAR DIFFERENTIAL DUST DEFLECTOR |

|

Using SST and a press, press out the dust deflector.

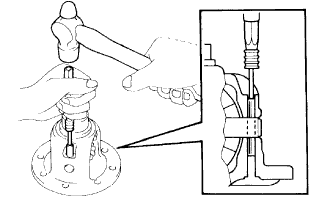

| 10. REMOVE REAR DIFFERENTIAL CARRIER OIL SEAL |

|

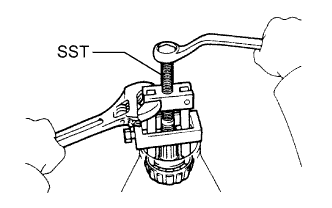

Using SST, remove the oil seal from the differential carrier.

| 11. REMOVE REAR DIFFERENTIAL DRIVE PINION OIL SLINGER |

| 12. REMOVE REAR DRIVE PINION FRONT TAPERED ROLLER BEARING |

|

Using SST, remove the roller bearing (inner) from the drive pinion.

| 13. REMOVE REAR DIFFERENTIAL BEARING ADJUSTING NUT LOCK |

|

Remove the 2 bolts and 2 adjusting locks.

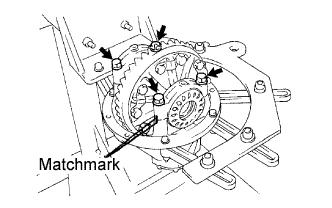

| 14. REMOVE DIFFERENTIAL CASE ASSEMBLY |

|

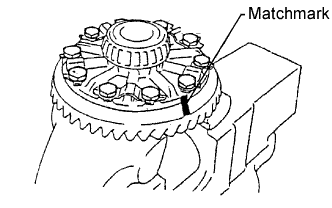

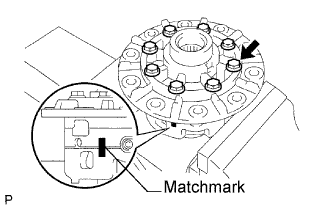

Place matchmarks on the bearing cap and differential carrier.

Remove the 4 bolts and 2 differential bearing caps.

Remove the 2 adjusting nuts.

|

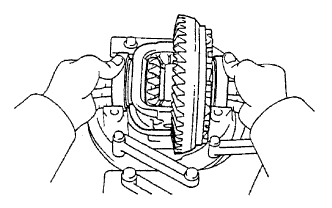

Remove the rear differential case bearings from the differential carrier.

| 15. REMOVE DIFFERENTIAL DRIVE PINION |

Remove the drive pinion and bearing spacer from the differential carrier.

| 16. REMOVE REAR DRIVE PINION REAR TAPERED ROLLER BEARING |

|

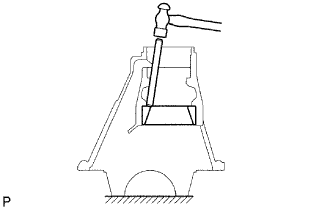

Using SST and a press, press out the roller bearing (inner) from the drive pinion.

| 17. REMOVE REAR DIFFERENTIAL DRIVE PINION PLATE WASHER |

| 18. REMOVE REAR DRIVE PINION FRONT TAPERED ROLLER BEARING |

|

Using SST, remove the roller bearing (outer) from the carrier.

Using a brass bar and hammer, tap out the oil storage ring from the carrier.

| 19. REMOVE REAR DRIVE PINION REAR TAPERED ROLLER BEARING |

|

Using a brass bar and hammer, tap out the rear tapered roller bearing (outer) from the carrier.

| 20. REMOVE DIFFERENTIAL RING GEAR |

|

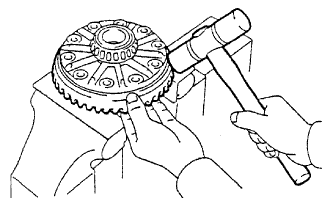

Place matchmarks on the ring gear and differential case.

Using a screwdriver and hammer, pry out the lock plates.

Remove the 10 ring gear set bolts and 5 lock plates.

|

Using a plastic-faced hammer, tap on the ring gear to separate it from the differential case.

| 21. INSPECT DIFFERENTIAL CASE ASSEMBLY RUNOUT |

|

Install the rear differential case bearing to the differential case.

Install the differential case to the differential carrier.

Install the 2 bearing caps to the differential carrier with the 4 bolts.

Inspect the differential case runout.

Remove the differential case.

Remove the rear differential case bearing.

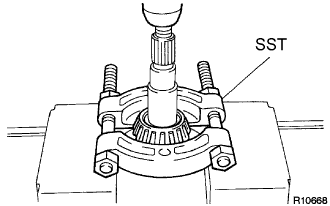

| 22. REMOVE REAR DIFFERENTIAL CASE BEARING |

|

Using SST, remove the 2 bearings from the differential case.

| 23. DISASSEMBLE DIFFERENTIAL CASE (for 2 Pinion Gear Type) |

|

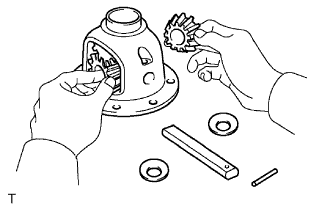

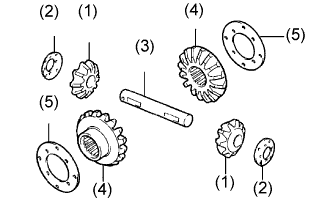

Using a pin punch and hammer, tap out the straight pin.

|

Remove the following parts from the differential case.

Using a chisel and hammer, unstake the differential case.

| 24. DISASSEMBLE DIFFERENTIAL CASE (for LSD) |

|

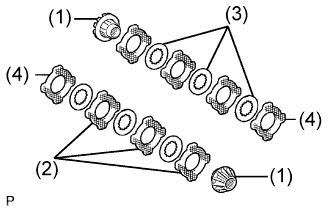

Place matchmarks on the LH and RH cases.

Remove the 8 bolts.

|

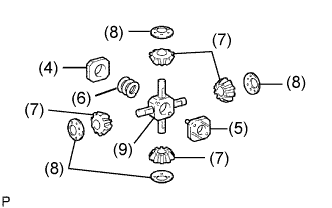

Remove the following parts from the differential cases.

|

| 25. INSPECT REAR NO. 1 DIFFERENTIAL SIDE GEAR THRUST WASHER (for LSD) |

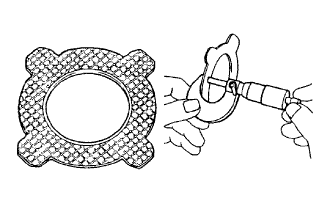

|

Using a micrometer, measure the thickness of the thrust washer. Also, check that there is no bare metal.

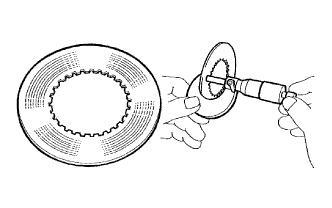

| 26. INSPECT CLUTCH PLATE (for LSD) |

|

Using a micrometer, measure the thickness of the clutch plate. Also, check that there is no abnormal wear.

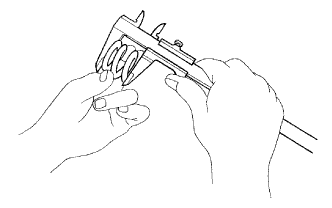

| 27. INSPECT COMPRESSION SPRING (for LSD) |

|

Using a vernier caliper, measure the free length of the spring.

| 28. INSPECT DIFFERENTIAL PINION AND SIDE GEAR |

Check that the differential pinion and differential side gear are not damaged.

| 29. INSPECT DIFFERENTIAL CASE |

Check that the differential case is not damaged.