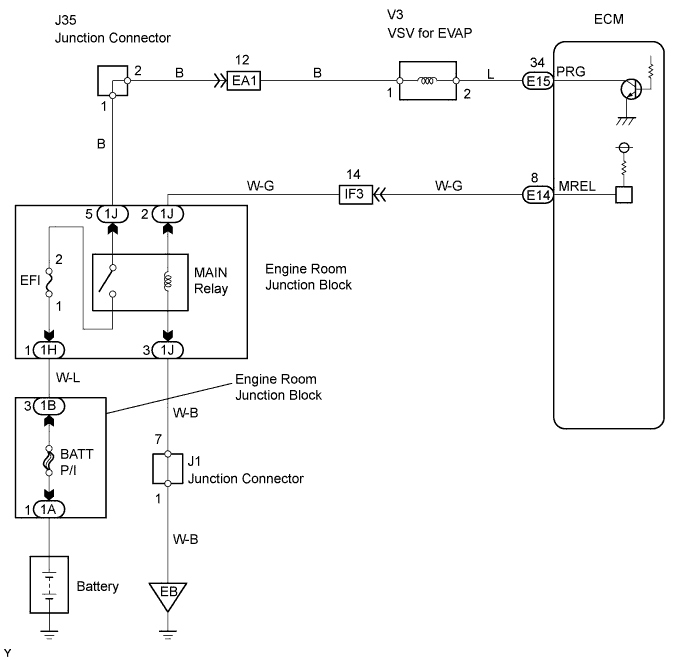

DTC P0443 Evaporative Emission Control System Purge Control Valve Circuit |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0443 | Proper response to ECM command does not occur (1 trip detection logic) |

|

| 1.PERFORM ACTIVE TEST (VSV for EVAP) |

|

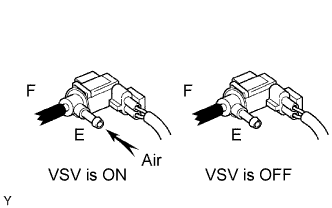

Disconnect the vacuum hose from the VSV for EVAP.

Connect the intelligent tester to the DLC3.

Enter the engine and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the VSV for EVAP Control. Press the right or left button.

Place a finger on port E. Check if the disconnected port applies suction to your finger when operating the VSV for EVAP using the intelligent tester.

| Tester Operation | Specified Condition |

| VSV is ON | Applies suction to your finger |

| VSV is OFF | Applies no suction to your finger |

|

| ||||

| NG | |

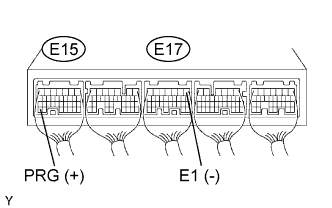

| 2.INSPECT ECM (PRG VOLTAGE) |

|

Turn the ignition switch ON.

Measure the voltage of the E15 and E17 ECM connectors.

| Tester Connection | Specified Condition |

| E15-34 (PRG) - E17-1 (E1) | 9 to 14 V |

|

| ||||

| NG | |

| 3.INSPECT VSV for EVAP |

|

| ||||

| OK | |

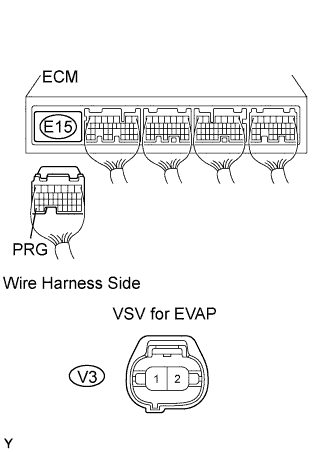

| 4.CHECK WIRE HARNESS (ECM - VSV for EVAP) |

|

Disconnect the E15 connector.

Disconnect the V3 VSV connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| V3-2 - E15-34 (PRG) | Below 1 Ω |

| V3-2 or E15-34 (PRG) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

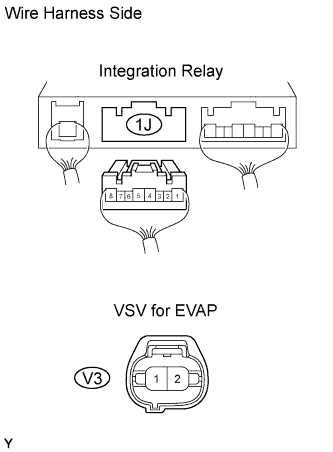

| 5.CHECK WIRE HARNESS (INTEGRATION RELAY - VSV for EVAP) |

|

Disconnect the 1J integration relay connector from the engine room junction block.

Disconnect the V3 VSV connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| V3-1 - 1J-5 | Below 1 Ω |

| V3-1 or 1J-5 - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||