REAR PROPELLER SHAFT ASSEMBLY > DISASSEMBLY |

| 1. REMOVE NO. 1 CENTER SUPPORT BEARING ASSEMBLY |

|

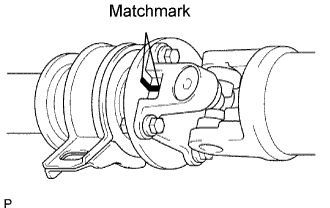

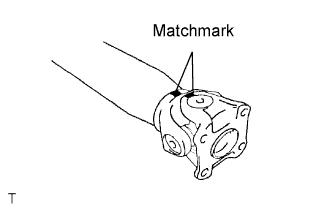

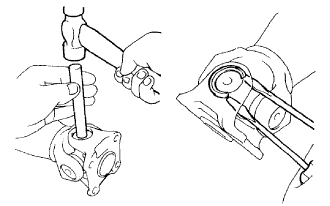

Place matchmarks on the flanges.

Remove the 4 nuts and 4 washers.

Separate the propeller shaft and intermediate shaft.

|

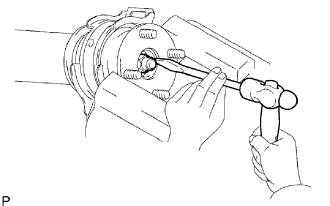

Fix the flange coupling at the center bearing section in a vise.

Using a chisel and hammer, loosen the staked part of the lock nut.

|

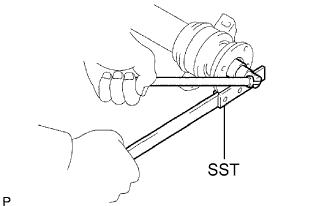

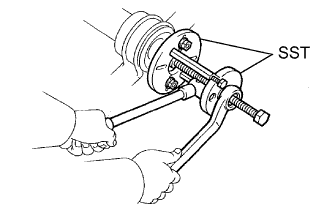

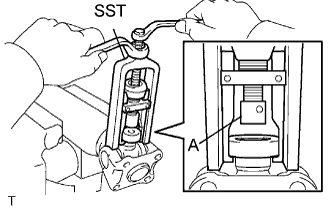

Using SST and a socket wrench, remove the nut and washer.

|

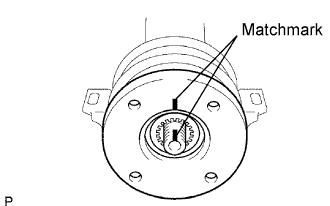

Place matchmarks on the intermediate shaft and flange coupling.

|

Using SST, remove the flange coupling from the intermediate shaft.

Remove the center support bearing.

| 2. INSPECT PROPELLER SHAFT AND INTERMEDIATE SHAFT |

|

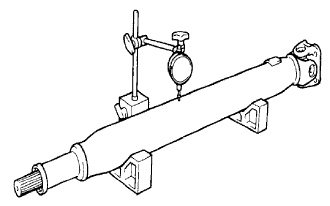

Using a dial indicator, measure the propeller shaft and intermediate shaft runout.

| Item | Specified Condition |

| Propeller shaft | 0.3 mm (0.012 in.) |

| Intermediate shaft | 0.5 mm (0.02 in.) |

| 3. INSPECT UNIVERSAL JOINT SPIDER ASSEMBLY |

Check the spider bearings for wear or damage.

Check each spider bearing's axial play by turning the yoke while holding the shaft tightly.

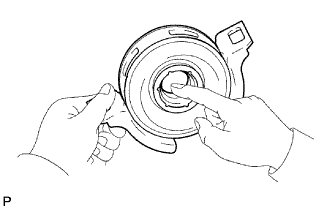

| 4. INSPECT NO. 1 CENTER SUPPORT BEARING ASSEMBLY |

|

When turning the center bearing with your hand, check that it turns smoothly without catching, and that there are no cracks or damage.

If there are any defects, replace it.

If there is any damage in the lip of the center bearing case, replace it.

| 5. REMOVE UNIVERSAL JOINT SPIDER ASSEMBLY |

|

Place matchmarks on the flange yoke and sleeve yoke.

|

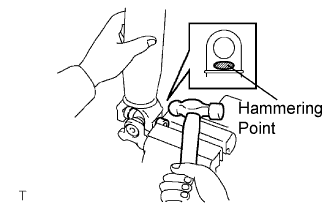

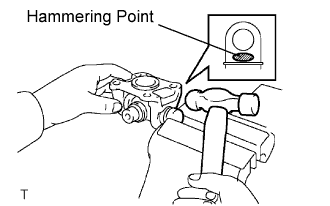

Using a brass bar and hammer, slightly tap in the spider bearing outer races.

Using 2 screwdrivers, remove the 4 snap rings from the grooves.

|

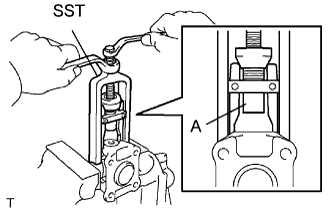

Clamp the propeller shaft in a vise between aluminum plates.

Using SST, push the sleeve yoke side spider bearing until: 1) the spider almost touches the sleeve yoke or propeller shaft, and 2) the spider bearing on the opposite side is partially pushed out.

|

Clamp the pushed out spider bearing outer race in a vise and tap the propeller shaft to remove the spider bearing.

Separate the flange yoke and spider from the propeller shaft.

|

Reinstall the 2 removed spider bearings to the spider and clamp the spider bearings in a vise.

Using SST, push the flange yoke side spider bearing until: 1) the spider almost touches the flange yoke, and 2) the spider bearing on the opposite side is partially pushed out.

|

Clamp the pushed out spider bearing outer race in a vise and tap the flange yoke to remove the spider bearing.

Separate the spider from the flange yoke.