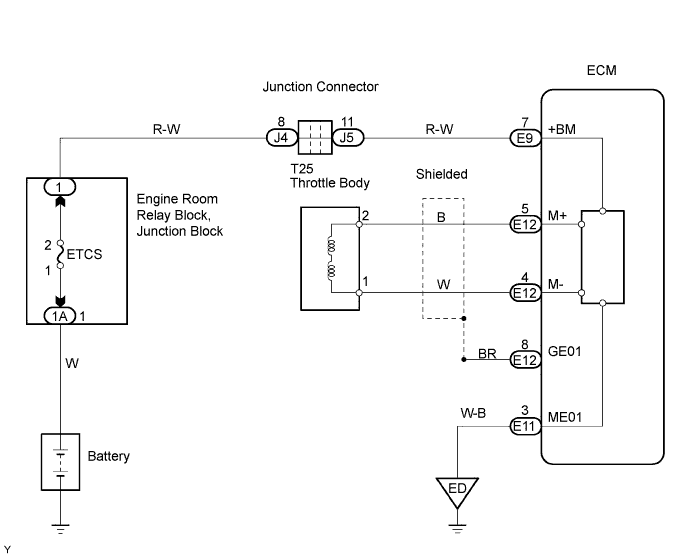

DTC P2102/41 Throttle Actuator Control Motor Circuit Low |

DTC P2103/41 Throttle Actuator Control Motor Circuit High |

| DTC No. | DTC Detection Condition | Suspected Area |

| P2102/41 | Conditions (a) and (b) continue for 2.0 seconds (1 trip detection logic):

|

|

| P2103/41 | Either of following conditions is met (1 trip detection logic):

|

|

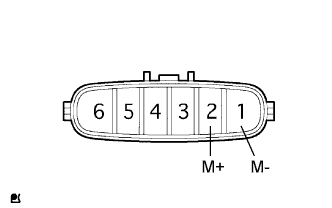

| 1.INSPECT THROTTLE BODY ASSEMBLY (RESISTANCE OF THROTTLE ACTUATOR) |

|

Disconnect the T25 throttle body connector.

Measure the resistance of the throttle actuator.

| Tester Connection | Specified Condition |

| 2 (M+) - 1 (M-) | 0.3 to 100 Ωat 20°C (68°F) |

|

| ||||

| OK | |

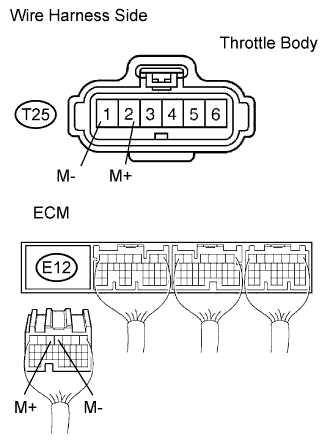

| 2.CHECK WIRE HARNESS (THROTTLE ACTUATOR - ECM) |

|

Disconnect the T25 throttle body connector.

Disconnect the E12 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| T25-2 (M+) - E12-5 (M+) | Below 1 Ω |

| T25-1 (M-) - E12-4 (M-) | Below 1 Ω |

| T25-2 (M+) or E12-5 (M+) - Body ground | 10 kΩ or higher |

| T25-1 (M-) or E12-4 (M-) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 3.INSPECT THROTTLE BODY ASSEMBLY |

Visually check for foreign objects between the throttle valve and housing.

Also, check that the valve can open and close smoothly.

|

| ||||

| OK | ||

| ||