DTC P0327/52 Knock Sensor 1 Circuit Low Input (Bank 1 or Single Sensor) |

DTC P0328/52 Knock Sensor 1 Circuit High Input (Bank 1 or Single Sensor) |

| DTC No. | DTC Detection Condition | Suspected Area |

| P0327/52 | Output voltage of the knock sensor is 0.5 V or less |

|

| P0328/52 | Output voltage of the knock sensor is 4.5 V or more |

|

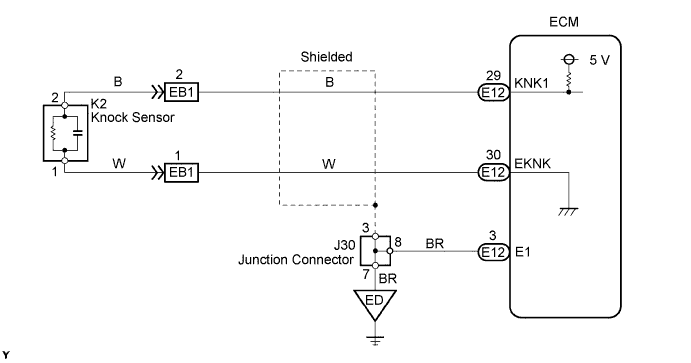

| 1.CHECK WIRE HARNESS (ECM - KNOCK SENSOR) |

|

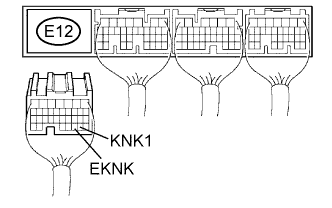

Disconnect the E12 ECM connector.

Measure the resistance of the wire harness side connector.

| Tester Connection | Condition | Specified Condition |

| E12-29 (KNK1) - E12-30 (EKNK) | 20°C (68°F) | 120 to 280 kΩ |

|

| ||||

| OK | |

| 2.CHECK ECM (KNK1 VOLTAGE) |

|

Turn the ignition switch ON.

Measure the voltage of the ECM connector.

| Tester Connection | Specified Condition |

| E12-29 (KNK1) - E12-30 (EKNK) | 4.5 to 5.5 V |

| Tester Connection | Specified Condition |

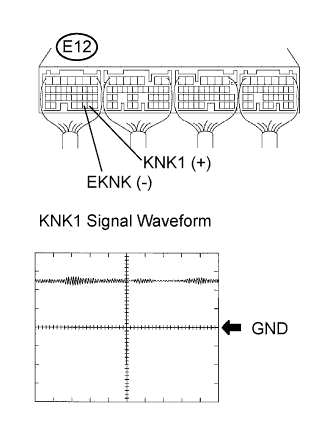

| E12-29 (KNK1) - E12-30 (EKNK) | Correct waveform is as shown |

| Tool Setting | Condition |

| 0.01 to 10 V/DIV., 0.01 to 10 msec./DIV. | After warming up engine, keep engine speed at 4,000 rpm |

|

| ||||

| OK | ||

| ||

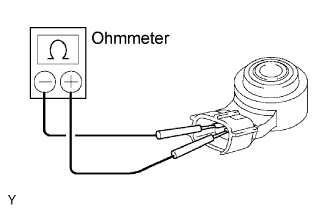

| 3.INSPECT KNOCK SENSOR |

|

Remove the sensor.

Measure the resistance of the sensor.

| Tester Connection | Condition | Specified Condition |

| 1 - 2 | 20°C (68°F) | 120 to 280 kΩ |

|

| ||||

| OK | ||

| ||