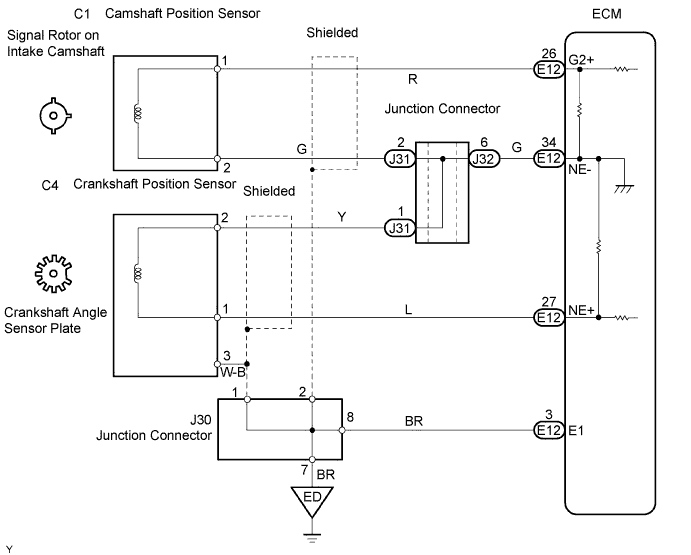

DTC P0335/13 Crankshaft Position Sensor "A" Circuit |

DTC P0339/13 Crankshaft Position Sensor "A" Circuit Intermittent |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0335/13 | No crankshaft position sensor signal to ECM at engine speed of 600 rpm or more (1 trip detection logic) |

|

| P0339/13 | In conditions (a), (b) and (c), when no crankshaft position sensor signal to ECM for 0.05 seconds or more.

|

|

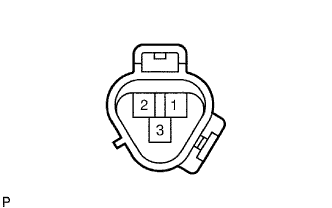

| 1.INSPECT CRANKSHAFT POSITION SENSOR (RESISTANCE) |

|

Disconnect the C4 sensor connector.

Measure the resistance of the sensor.

| Tester Connection | Sensor Condition | Specified Condition |

| 1 - 2 | Cold | 1,630 to 2,740 Ω |

| 1 - 2 | Hot | 2,065 to 3,225 Ω |

|

| ||||

| OK | |

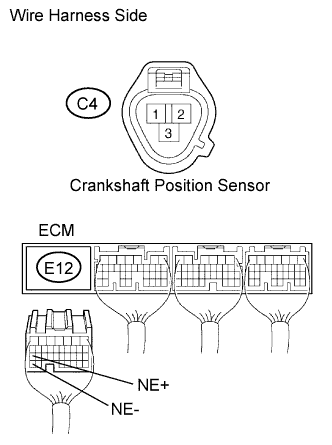

| 2.CHECK WIRE HARNESS (CRANKSHAFT POSITION SENSOR - ECM) |

|

Disconnect the C4 sensor connector.

Disconnect the E12 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| C4-1 - E12-27 (NE+) | Below 1 Ω |

| C4-2 - E12-34 (NE-) | Below 1 Ω |

| C4-1 or E12-27 (NE+) - Body ground | 10 kΩ or higher |

| C4-2 or E12-34 (NE-) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

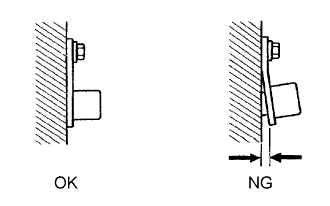

| 3.CHECK SENSOR INSTALLATION (CRANKSHAFT POSITION SENSOR) |

|

Check that the crankshaft position sensor is installed correctly.

|

| ||||

| OK | |

| 4.CHECK CRANKSHAFT POSITION SENSOR PLATE (TEETH OF SENSOR PLATE (CRANKSHAFT)) |

Check that the teeth of the sensor plate do not have any cracks or deformation.

|

| ||||

| OK | ||

| ||