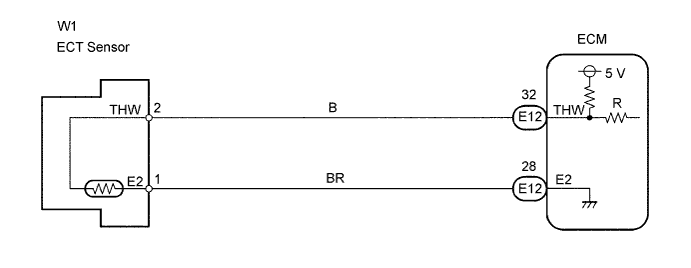

DTC P0115/22 Engine Coolant Temperature Circuit |

DTC P0117/22 Engine Coolant Temperature Circuit Low Input |

DTC P0118/22 Engine Coolant Temperature Circuit High Input |

| DTC No. | DTC Detection Condition | Suspected Area |

| P0115/22 | Open or short in ECT sensor circuit for 0.5 seconds |

|

| P0117/22 | Short in ECT sensor circuit for 0.5 seconds |

|

| P0118/22 | Open in ECT sensor circuit for 0.5 seconds |

|

| Temperature Displayed | Malfunction |

| -40°C (-40°F) | Open circuit |

| 140°C (284°F) or more | Short circuit |

| 1.READ OUTPUT DTC |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read DTCs.

| Display (DTC Output) | Proceed to |

| P0115/22 | A |

| P0117/22 | B |

| P0118/22 | C |

|

| ||||

|

| ||||

| A | |

| 2.READ DATA LIST (ENGINE COOLANT TEMPERATURE) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Coolant Temp.

Read the value.

| Temperature Displayed | Proceed to |

| -40°C (-40°F) | A |

| 140°C (284°F) or more | B |

| OK (same as the actual engine coolant temperature) | C |

|

| ||||

|

| ||||

| A | |

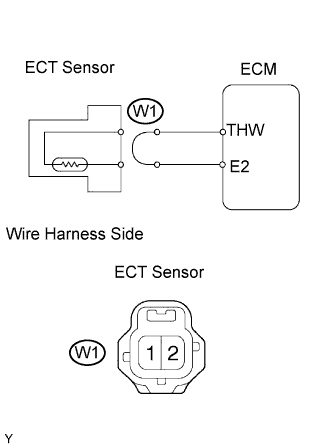

| 3.READ DATA LIST (CHECK FOR OPEN IN WIRE HARNESS) |

|

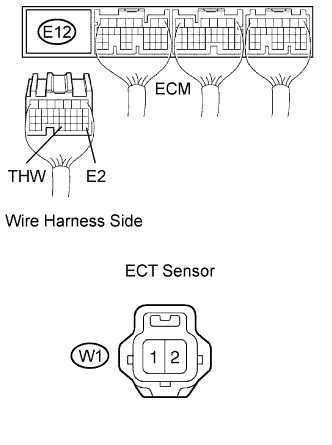

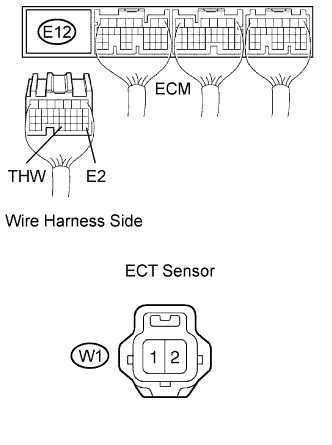

Disconnect the W1 ECT sensor connector.

Connect terminals 1 and 2 of the W1 ECT sensor wire harness side connector.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Coolant Temp.

Read the value.

|

| ||||

| NG | |

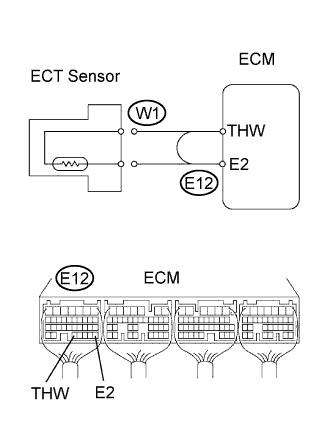

| 4.READ DATA LIST (CHECK FOR OPEN IN ECM) |

|

Disconnect the W1 ECT sensor connector.

Connect terminals THW and E2 of the E12 ECM connector.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Coolant Temp.

Read the value.

|

| ||||

| NG | ||

| ||

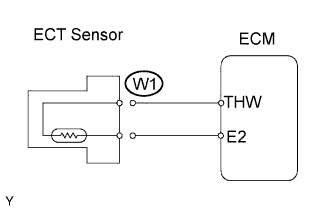

| 5.READ DATA LIST (CHECK FOR SHORT IN WIRE HARNESS) |

|

Disconnect the W1 ECT sensor connector.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Coolant Temp.

Read the value.

|

| ||||

| NG | |

| 6.CHECK WIRE HARNESS (ECM - ENGINE COOLANT TEMPERATURE SENSOR) |

|

Disconnect the E12 ECM connector.

Disconnect the W1 ECT sensor connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| E12-32 (THW) - W1-2 | Below 1 Ω |

| E12-28 (E2) - W1-1 | Below 1 Ω |

| E12-32 (THW) or W1-2 - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||

| 1.CHECK ECM (THW VOLTAGE) |

|

Turn the ignition switch ON.

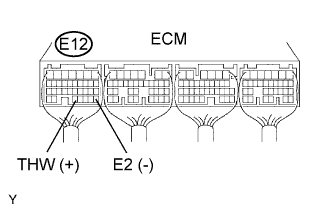

Measure the voltage between terminals THW and E2 of the ECM connector.

| Engine Coolant Temperature | Specified Condition |

| 20°C (68°F) | 0.5 to 3.4 V |

| 80°C (176°F) | 0.2 to 1.0 V |

|

| ||||

| NG | |

| 2.INSPECT ENGINE COOLANT TEMPERATURE SENSOR |

Inspect the ECT sensor (Click here).

|

| ||||

| OK | |

| 3.CHECK WIRE HARNESS (ECM - ENGINE COOLANT TEMPERATURE SENSOR) |

|

Disconnect the E12 ECM connector.

Disconnect the W1 ECT sensor connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| E12-32 (THW) - W1-2 | Below 1 Ω |

| E12-28 (E2) - W1-1 | Below 1 Ω |

| E12-32 (THW) or W1-2 - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||