DTC B1800/51 Short in Driver Side Squib Circuit |

DTC B1801/51 Open in Driver Side Squib Circuit |

DTC B1802/51 Short to GND in Driver Side Squib Circuit |

DTC B1803/51 Short to B+ in Driver Side Squib Circuit |

| DTC No. | DTC Detection Condition | Trouble Area |

| B1800/51 | Center airbag sensor assembly receives line short circuit signal 5 times in driver squib circuit during primary check |

|

| B1801/51 | Center airbag sensor assembly receives open circuit signal in driver squib circuit for 2 seconds |

|

| B1802/51 | Center airbag sensor assembly receives short circuit to ground signal in driver squib circuit for 0.5 seconds |

|

| B1803/51 | Center airbag sensor assembly receives B+ short circuit signal in driver squib circuit for 0.5 seconds |

|

| 1.CHECK FOR DTC |

Proceed to each step according to DTC readings.

If using the intelligent tester (read the 5 digit DTC):

Check for DTCs (Click here).

| Result | Proceed to |

| DTC B1800 is output | A |

| DTC B1801 is output | B |

| DTC B1802 is output | C |

| DTC B1803 is output | D |

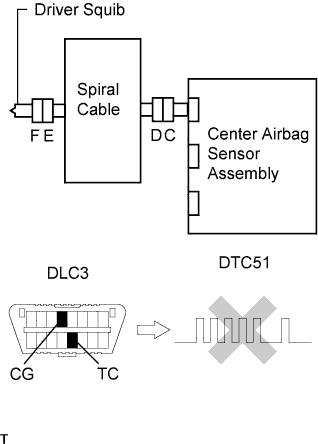

If not using the intelligent tester (read the 2 digit DTC):

Check for DTC (Click here).

| Result | Proceed to |

| DTC 51 is output | E |

|

| ||||

|

| ||||

|

| ||||

|

| ||||

| A | |

| 2.CHECK CONNECTOR |

Turn the ignition switch OFF.

Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

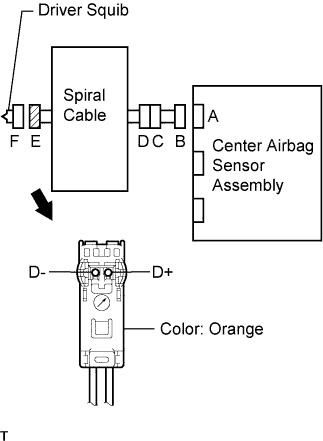

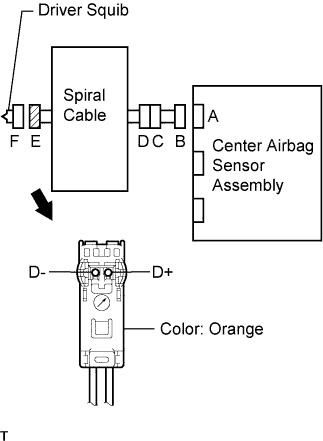

Check that the spiral cable connector (on the steering pad side) is not damaged.

|

| ||||

| OK | |

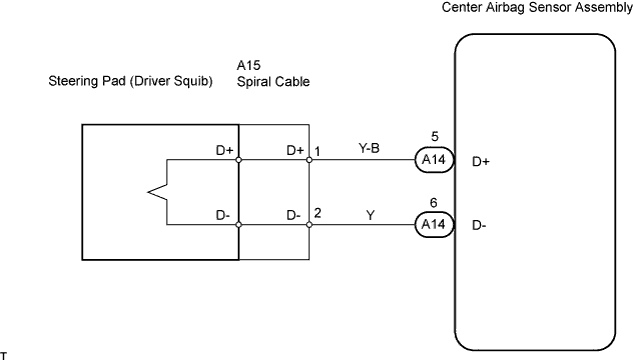

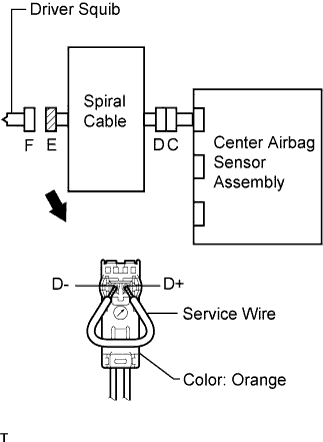

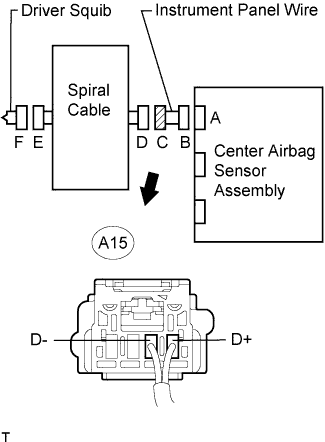

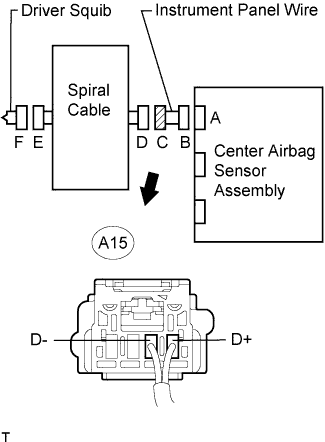

| 3.CHECK DRIVER SQUIB CIRCUIT (SHORT) |

|

Disconnect the connectors from the center airbag sensor and steering pad (Click here).

Release the activation prevention mechanism built into connector B.

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - D- | 1 MΩ or higher |

|

| ||||

|

| ||||

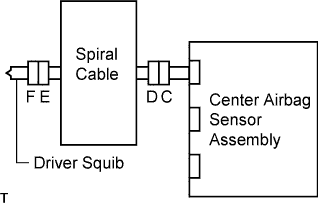

| 4.CHECK DRIVER SQUIB CIRCUIT (OPEN) |

|

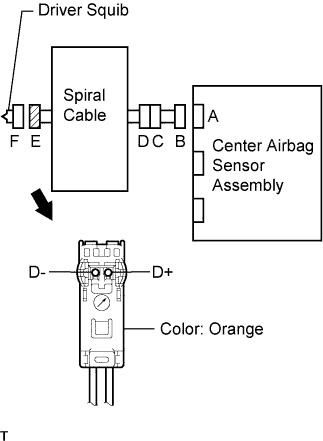

Disconnect the connectors from the center airbag sensor and steering pad.

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - D- | Below 1 Ω |

|

| ||||

|

| ||||

| 5.CHECK DRIVER SQUIB CIRCUIT (TO GROUND) |

|

Disconnect the connectors from the center airbag sensor and steering pad.

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - Body ground | 1 MΩ or higher |

| D- - Body ground | 1 MΩ or higher |

|

| ||||

|

| ||||

| 6.CHECK DRIVER SQUIB CIRCUIT (TO B+) |

|

Disconnect the connectors from the center airbag sensor and steering pad.

Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

Turn the ignition switch ON.

Measure the voltage of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - Body ground | Below 1 V |

| D- - Body ground | Below 1 V |

Turn the ignition switch OFF.

Disconnect the cable from the negative (-) battery terminal and wait for at least 90 seconds.

|

| ||||

|

| ||||

| 7.CHECK CONNECTOR |

Check that the spiral cable connector (on the steering pad side) is not damaged.

|

| ||||

| OK | |

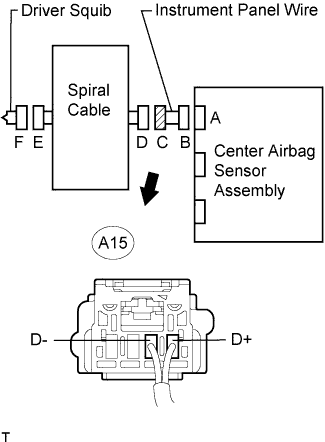

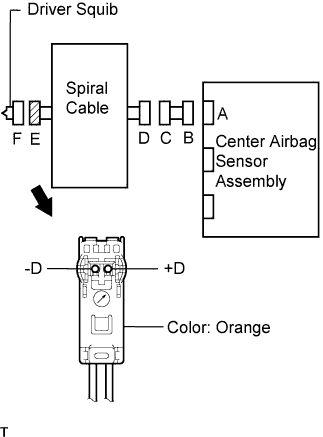

| 8.CHECK DRIVER SQUIB CIRCUIT |

|

Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

Turn the ignition switch ON.

Measure the voltage of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - Body ground | Below 1 V |

| D- - Body ground | Below 1 V |

Turn the ignition switch OFF.

Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - D- | Below 1 Ω |

| D+ - Body ground | 1 MΩ or higher |

| D- - Body ground | 1 MΩ or higher |

Release the activation prevention mechanism built into connector B (Click here).

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - D- | 1 MΩ or higher |

|

| ||||

| OK | |

| 9.REPLACE SPIRAL CABLE (DRIVER SQUIB) |

|

Replace the steering pad (Click here).

Connect the connector to the center airbag sensor.

Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

Turn the ignition switch ON, and wait for at least 60 seconds.

Clear the DTCs (Click here).

Turn the ignition switch OFF.

Turn the ignition switch ON, and wait for at least 60 seconds.

Check for DTCs (Click here).

|

| ||||

| OK | ||

| ||

| 10.CHECK CENTER AIRBAG SENSOR ASSEMBLY |

|

Connect the connector to the center airbag sensor.

Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

Turn the ignition switch ON, and wait for at least 60 seconds.

Clear the DTCs (Click here).

Turn the ignition switch OFF.

Turn the ignition switch ON, and wait for at least 60 seconds.

Check for DTCs (Click here).

Turn the ignition switch OFF.

Disconnect the cable from the negative (-) battery terminal and wait for at least 90 seconds.

|

| ||||

| NG | ||

| ||

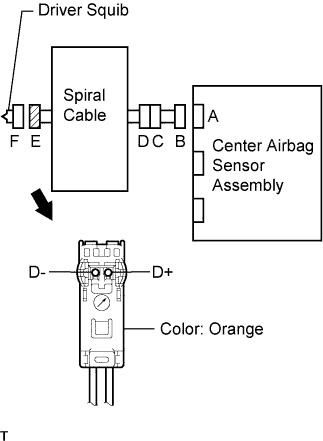

| 11.CHECK CENTER AIRBAG SENSOR ASSEMBLY |

|

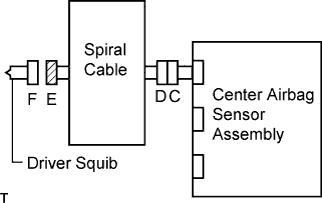

Connect the connector to the center airbag sensor.

Using a service wire, connect terminals D+ and D- of connector E.

Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

Turn the ignition switch ON, and wait for at least 60 seconds.

Clear the DTCs (Click here).

Turn the ignition switch OFF.

Turn the ignition switch ON, and wait for at least 60 seconds.

Check for DTCs (Click here).

|

| ||||

| OK | |

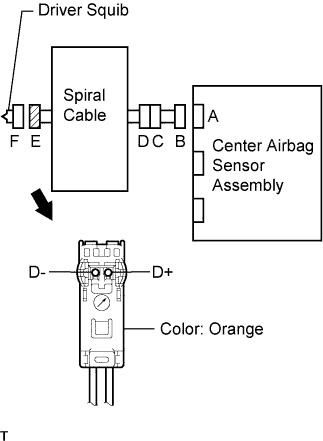

| 12.CHECK STEERING PAD (DRIVER SQUIB) |

|

Disconnect the service wire from connector E.

Connect the connector to the steering pad (driver squib).

Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

Turn the ignition switch ON, and wait for at least 60 seconds.

Clear the DTCs (Click here).

Turn the ignition switch OFF.

Turn the ignition switch ON, and wait for at least 60 seconds.

Check for DTCs (Click here).

|

| ||||

| OK | ||

| ||

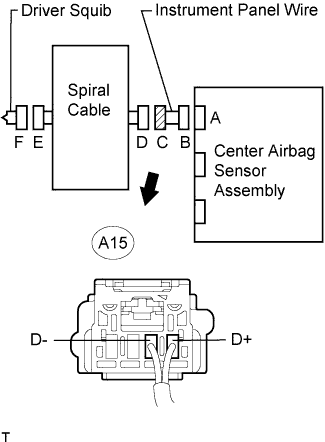

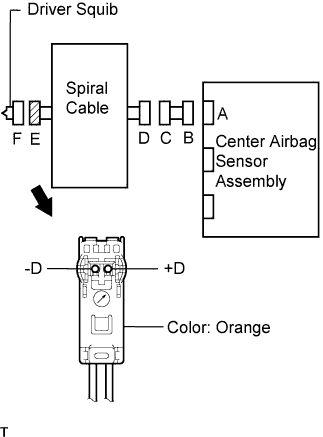

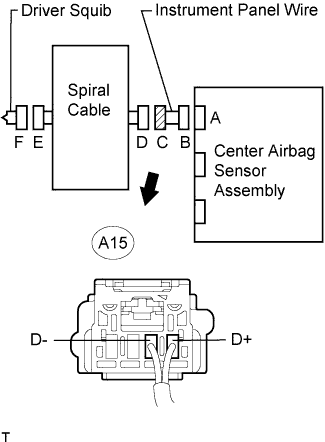

| 13.CHECK INSTRUMENT PANEL WIRE (SHORT) |

|

Disconnect the instrument panel wire connector from the spiral cable.

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| A15-1 (D+) - A15-2 (D-) | 1 MΩ or higher |

|

| ||||

| OK | |

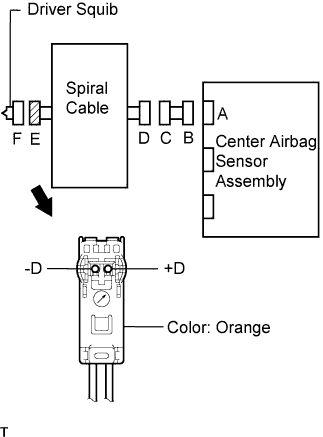

| 14.CHECK SPIRAL CABLE (SHORT) |

|

Release the activation prevention mechanism built into connector D (Click here).

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - D- | 1 MΩ or higher |

|

| ||||

| OK | ||

| ||

| 15.CHECK INSTRUMENT PANEL WIRE (OPEN) |

|

Disconnect the instrument panel wire connector from the spiral cable.

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| A15-1 (D+) - A15-2 (D-) | Below 1 Ω |

|

| ||||

| OK | |

| 16.CHECK SPIRAL CABLE (OPEN) |

|

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - D- | Below 1 Ω |

|

| ||||

| OK | ||

| ||

| 17.CHECK INSTRUMENT PANEL WIRE (TO GROUND) |

|

Disconnect the instrument panel wire connector from the spiral cable.

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| A15-1 (D+) - Body ground | 1 MΩ or higher |

| A15-2 (D-) - Body ground | 1 MΩ or higher |

|

| ||||

| OK | |

| 18.CHECK SPIRAL CABLE (TO GROUND) |

|

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - Body ground | 1 MΩ or higher |

| D- - Body ground | 1 MΩ or higher |

|

| ||||

| OK | ||

| ||

| 19.CHECK INSTRUMENT PANEL WIRE (TO B+) |

|

Disconnect the instrument panel wire connector from the spiral cable.

Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

Turn the ignition switch ON.

Measure the voltage of the wire harness side connector.

| Tester Connection | Specified Condition |

| A15-1 (D+) - Body ground | Below 1 V |

| A15-2 (D-) - Body ground | Below 1 V |

|

| ||||

| OK | |

| 20.CHECK SPIRAL CABLE (TO B+) |

|

Turn the ignition switch ON.

Measure the voltage of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - Body ground | Below 1 V |

| D- - Body ground | Below 1 V |

|

| ||||

| OK | ||

| ||

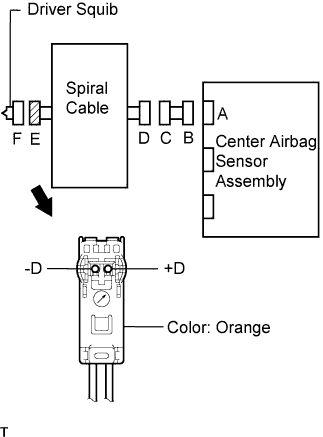

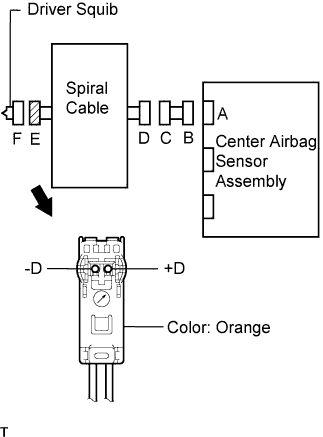

| 21.CHECK INSTRUMENT PANEL WIRE |

|

Restore the released activation prevention mechanism of connector B to its original position.

Disconnect the instrument panel wire connector from the spiral cable.

Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

Turn the ignition switch ON.

Measure the voltage of the wire harness side connector.

| Tester Connection | Specified Condition |

| A15-1 (D+) - Body ground | Below 1 V |

| A15-2 (D-) - Body ground | Below 1 V |

Turn the ignition switch OFF.

Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| A15-1 (D+) - A15-2 (D-) | Below 1 Ω |

| A15-1 (D+) - Body ground | 1 MΩ or higher |

| A15-2 (D-) - Body ground | 1 MΩ or higher |

Release the activation prevention mechanism built into connector B (Click here).

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| A15-1 (D+) - A15-2 (D-) | 1 MΩ or higher |

|

| ||||

| OK | |

| 22.CHECK SPIRAL CABLE |

|

Reconnect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

Turn the ignition switch ON.

Measure the voltage of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - Body ground | Below 1 V |

| D- - Body ground | Below 1 V |

Turn the ignition switch OFF.

Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - D- | Below 1 Ω |

| D+ - Body ground | 1 MΩ or higher |

| D- - Body ground | 1 MΩ or higher |

Release the activation prevention mechanism built into connector D (Click here).

Measure the resistance of the wire harness side connector.

| Tester Connection | Specified Condition |

| D+ - D- | 1 MΩ or higher |

|

| ||||

| OK | ||

| ||