ENGINE > INSPECTION |

| 1. INSPECT ENGINE COOLANT |

Remove radiator cap.

Check if there are excessive deposits of rust or scale around the radiator cap and radiator filler hole. Also, the coolant should be free of oil.

If excessively dirty, replace the coolant.

Install the radiator cap.

| 2. INSPECT ENGINE OIL |

Warm up the engine, stop the engine and wait 5 minutes. The oil level should be between the dipsticks low and full level marks.

If low, check for leakage and add oil up to the full level mark.

| 3. INSPECT BATTERY |

Check the battery for damage and deformation. If severe damage, deformation or leakage is found, replace the battery.

Check the electrolyte quantity of each cell.

For maintenance-free batteries:

| 4. CHECK AIR CLEANER FILTER |

Remove the air filter.

Visually check that the air filter is not excessively damaged or oily.

If necessary, replace the air filter.

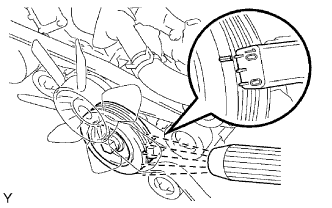

| 5. INSPECT DRIVE BELT |

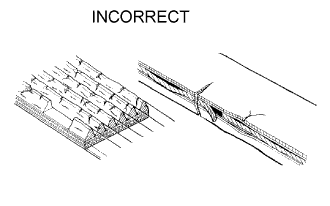

|

Visually check the drive belt for excessive wear, frayed cords, etc.

If any defect is found, replace the drive belt.

| 6. INSPECT V-RIBBED BELT TENSIONER |

Check that nothing gets caught in the tensioner by turning it clockwise and counterclockwise.

If a malfunction exists, replace the tensioner.

| 7. INSPECT IGNITION TIMING |

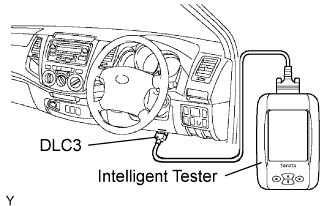

|

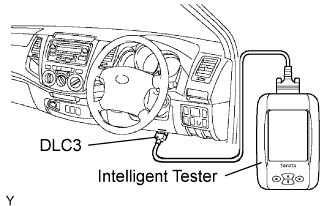

When using intelligent tester:

Check the ignition timing.

Connect the intelligent tester to the DLC3.

Disconnect the intelligent tester from the DLC3.

|

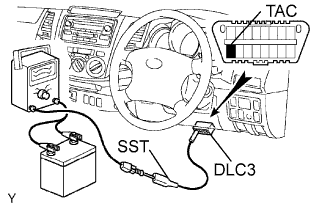

When not using intelligent tester.

Check the ignition timing.

Remove the air cleaner cap.

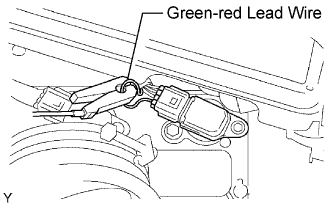

Connect the tester probe of a timing light to the green-red read wire of the ignition coil connector for the No.1 cylinder.

|

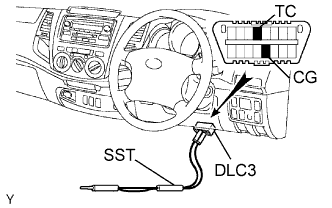

Using SST, connect terminals TC and CG of the DLC3.

|

Using the timing light, check the ignition timing.

Remove the SST from the DLC3.

Check the ignition timing.

Disconnect the timing light from the engine.

Install the air cleaner cap.

| 8. INSPECT IDLE SPEED |

|

When using intelligent tester:

Check the idle speed.

Connect the intelligent tester to the DLC3.

Switch the air conditioning OFF.

Race the engine at 2,500 rpm for approximately 90 seconds.

Check the idle speed.

Disconnect the intelligent tester from the DLC3.

|

When not using intelligent tester:

Check the idle speed.

Using SST, connect tachometer probe to terminal TAC of the DLC3.

Switch the air conditioning OFF.

Race the engine speed at 2,500 rpm for approximately 90 seconds.

Check the idle speed.

Disconnect the tachometer from the DLC3.

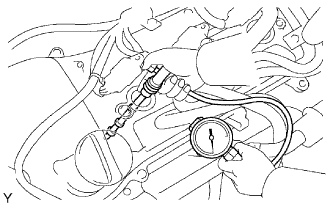

| 9. INSPECT COMPRESSION |

Remove the V-bank cover.

Remove the air cleaner assembly.

Remove the intake air surge tank.

Remove the 6 ignition coils.

Remove the 6 spark plugs.

Disconnect the 6 injector connectors.

|

Inspect the cylinder compression pressure.

Insert a compression gauge into the spark plug hole.

Fully open the throttle.

While cranking the engine, measure the compression pressure.

Repeat steps above procedure for each cylinder.

If the cylinder compression in one or more cylinders is low, pour a small amount of engine oil into the cylinder through the spark plug hole and repeat above steps for cylinders with low compression.

Connect the 6 injector connectors.

Install the 6 spark plugs.

Install the 6 ignition coils.

Install the intake air surge tank.

Install the air cleaner assembly.

Install the V-bank cover.

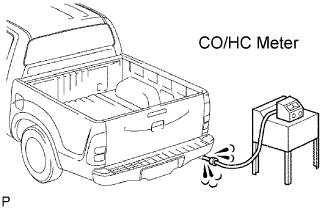

| 10. INSPECT CO/HC |

Start the engine.

Keep the engine speed at 2,500 rpm for approximately 180 seconds.

|

Insert CO/HC meter testing probe at least 40 cm (1.3 ft.) into the tailpipe during idling.

Immediately check CO/HC concentration at idle and/or 2,500 rpm.

Check the A/F sensor operation and heated oxygen sensor operation.

See the table below for possible causes, then inspect and correct the applicable causes if necessary.

| CO | HC | Symptom | Causes |

| Normal | High | Rough idle | 1. Faulty ignitions:

3. Leaky intake and exhaust valves 4. Leaky cylinder |

| Low | High | Rough idle (Fluctuating HC reading) | 1. Vacuum leaks:

|

| High | High | Rough idle (Black smoke from exhaust) | 1. Restricted air filter 2. Faulty SFI system:

|