LUBRICATION SYSTEM > ON-VEHICLE INSPECTION |

| 1. CHECK ENGINE OIL LEVEL |

Warm up the engine, stop the engine and wait 5 minutes. The oil level should be between the dipsticks low and full level marks.

If low, check for leakage and add oil up to the full level mark.

| 2. CHECK ENGINE OIL QUALITY |

Check the oil for deterioration, water contamination, discoloring or thinning.

If the oil quality is visibly poor, replace the oil.

| 3. REMOVE OIL PRESSURE SWITCH |

Disconnect the oil pressure switch connector.

Using a 24 mm deep socket wrench, remove the oil pressure switch.

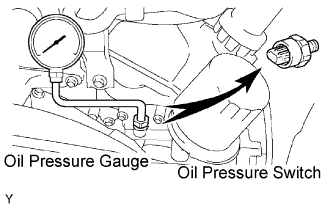

| 4. INSTALL OIL PRESSURE GAUGE |

|

Install the oil pressure gauge.

| 5. WARM UP ENGINE |

| 6. CHECK OIL PRESSURE |

| Condition | Specified Condition |

| Idle | 29 kPa (0.3 kgf/cm2, 4.2 psi) or more |

| 3,000 rpm | 294 to 588 kPa (3.0 to 6.0 kgf/cm2, 43 to 85 psi) |

| 7. INSTALL ENGINE OIL PRESSURE SWITCH |

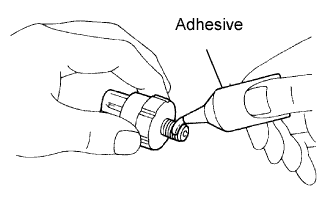

|

Remove the oil pressure gauge.

Apply adhesive to 2 or 3 threads of the oil pressure switch.

Using a 24 mm deep socket wrench, Install the oil pressure switch.

Connect the oil pressure switch connector.

| 8. START ENGINE AND CHECK FOR LEAKS |