DTC P0234/34 Turbocharger / Supercharger Overboost Condition |

DTC P0299/34 Turbocharger / Supercharger Underboost |

DTC P1251/34 Step Motor for Turbocharger Control Circuit (Intermittent) |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0234/34 | When turbocharger boost pressure continues to be higher than ECM's target boost pressure. (1 trip detection logic) |

|

| P0299/34 | When turbocharger boost pressure continues to be lower than ECM's target boost pressure. (1 trip detection logic) |

|

| P1251/34 | When turbocharger boost pressure is higher than boost pressure for a short time in which there was possibility of engine damage. (1 trip detection logic) |

|

| 1.CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P0234/34, P0299/34 AND /OR P1251/34) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / DTC.

Read the DTCs.

| Display (DTC Output) | Proceed to |

| P0234/34, P0299/34 and/or P1251/34 | A |

| P0234/34, P0299/34 and/or P1251/34 and other DTCs | B |

|

| ||||

| A | |

| 2.READ DATA LIST (MAP) |

Connect the intelligent tester to the DLC3.

Start the engine and warm it up. Turn the intelligent tester ON.

Enter the following menu: Powertrain / Engine / Data List / MAP.

| Item | Engine Speed* | Reference Value |

| MAP | Ignition switch ON | Same as atmospheric pressure |

| MAP | Idling | 95 to 105 kPa (713 to 788 mmHg, 28.1 to 31 in.Hg) |

| MAP | 3,000 rpm (no engine load) | 110 to 135 kPa (825 to 1,012 mm Hg, 32.5 to 39.9 in.Hg) |

|

| ||||

| OK | |

| 3.CHECK EXHAUST SYSTEM |

Turn the ignition switch ON.

Check the exhaust pipe for leaks.

|

| ||||

| OK | |

| 4.CHECK AIR CLEANER FILTER |

Check that the air cleaner filter is not clogged.

|

| ||||

| OK | |

| 5.CHECK INTAKE SYSTEM |

Disconnect the air cleaner hose.

Use a mirror to visually check the turbocharger for any mechanical problems.

When the engine is cold, check that the impeller of the turbocharger rotates smoothly, and perform a contact check to confirm whether there is any damage on it.

|

| ||||

| OK | |

| 6.INSPECT TURBOCHARGER SUB-ASSEMBLY |

Disconnect the air cleaner hose.

Use a mirror to visually check the turbocharger for any mechanical problems.

When the engine is cold, check that the impeller of the turbocharger rotates smoothly, and perform a contact check to confirm whether there is any damage on it.

|

| ||||

| OK | |

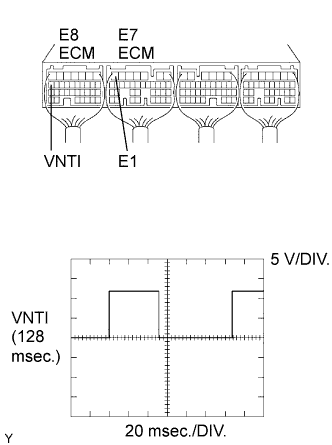

| 7.CHECK ECM (VNTI VOLTAGE) |

|

While idling the engine, check the waveform of the ECM connectors using an oscilloscope.

| Tester Connection | Specified Condition |

| E8-17 (VNTI) - E7-7 (E1) | Correct waveform is shown |

|

| ||||

| OK | |

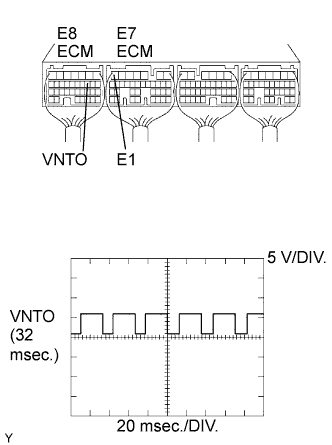

| 8.CHECK ECM (VNTO VOLTAGE) |

|

While idling the engine, check the waveform of the ECM connectors using an oscilloscope.

| Tester Connection | Specified Condition |

| E8-10 (VNTO) - E7-7 (E1) | Correct waveform is shown |

|

| ||||

| OK | |

| 9.CHECK EGR VALVE ASSEMBLY |

|

| ||||

| OK | |

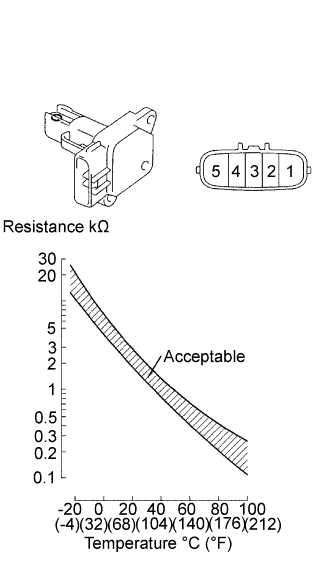

| 10.INSPECT INTAKE AIR TEMPERATURE SENSOR |

|

Check the IAT sensor.

Remove the MAF meter.

Measure the resistance of the sensor.

| Tester Connection | Condition | Specified Condition |

| 4 - 5 | -20°C (-4°F) | 13.6 to 18.4 kΩ |

| 4 - 5 | 20°C (68°F) | 2.21 to 2.69 kΩ |

| 4 - 5 | 60°C (140°F) | 0.49 to 0.67 kΩ |

|

| ||||

| OK | ||

| ||