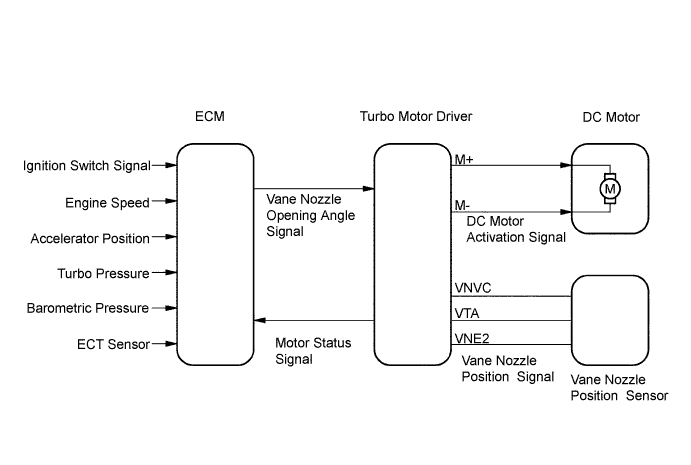

DTC P0045/34 Turbocharger / Supercharger Boost Control Solenoid Circuit / Open |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0045/34 |

|

|

| 1.INSPECT TURBOCHARGER SUB-ASSY (DC MOTOR) |

|

| ||||

| OK | |

| 2.INSPECT TURBO MOTOR DRIVER |

|

| ||||

| OK | |

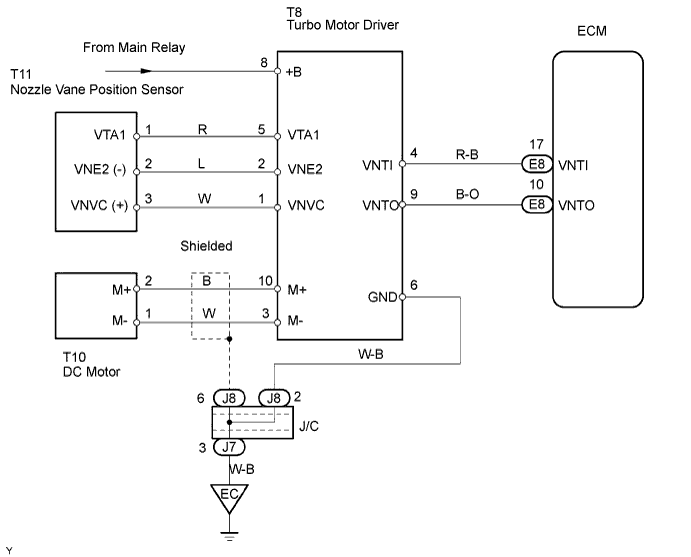

| 3.CHECK WIRE HARNESS (TURBO MOTOR DRIVER - ECM) |

|

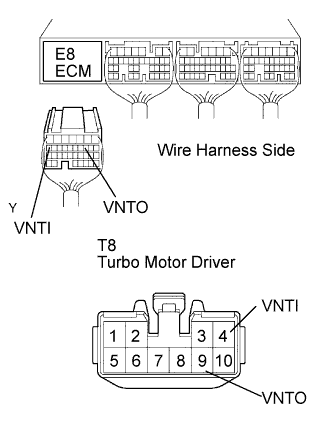

Disconnect the E8 ECM connector.

Disconnect the T8 turbo motor driver connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| E8-10 (VNTO) - T8-9 (VNTO) E8-17 (VNTI) - T8-4 (VNTI) | Below 1 Ω |

| E8-10 (VNTO) or T8-9 (VNTO) - Body ground E8-17 (VNTI) or T8-4 (VNTI) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 4.CHECK WIRE HARNESS (TURBO MOTOR DRIVE - NOZZLE VANE POSITION SENSOR, TURBO MOTOR DRIVE - DC MOTOR) |

|

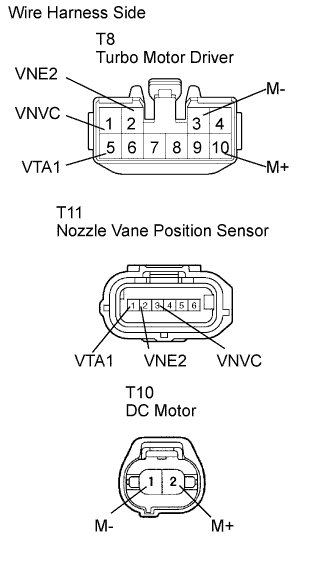

Disconnect the T8 turbo motor drive connector.

Disconnect the T11 nozzle vane position sensor connector.

Disconnect the T10 DC motor connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| T8-1 (VNVC) - T11-3 (VNVC) T8-5 (VTA1) - T11-1 (VTA1) T8-2 (VNE2) - T11-2 (VNE2) T8-10 (M+) - T10-2 (M+) T8-3 (M-) - T10-1 (M-) | Below 1 Ω |

| T8-1 (VNVC) or T11-3 (VNVC) - Body ground T8-5 (VTA1) or T11-1 (VTA1) - Body ground T8-2 (VNE2) or T11-2 (VNE2) - Body ground T8-10 (M+) or T10-2 (M+) - Body ground T8-3 (M-) or T10-1 (M-) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||