DTC P0100/31 Mass or Volume Air Flow Circuit |

DTC P0102/31 Mass or Volume Air Flow Circuit Low Input |

DTC P0103/31 Mass or Volume Air Flow Circuit High Input |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0100/31 | When MAF meter circuit has open or short for more than 3 seconds under 2,000 rpm engine speed (1 trip detection logic) |

|

| P0102/31 | When MAF meter circuit has open for more than 3 seconds under 2,000 rpm engine speed (1 trip detection logic) |

|

| P0103/31 | When MAF meter circuit has short for more than 3 seconds under 2,000 rpm engine speed (1 trip detection logic) |

|

| Air Flow Rate (gm/s) | Malfunction |

| Approximately 0.0 |

|

| 174.0 or more | Open in EVG circuit |

| 1.READ DATA LIST (MASS AIR FLOW RATE) |

Connect the intelligent tester to the DLC3.

Start the engine and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / Data List / MAF.

Read the values.

| Air Flow Rate (gm/s) | Proceed to |

| 0.0 | A |

| 174.0 or more | B |

| Between 1 and 173.0* | C |

|

| ||||

|

| ||||

| A | |

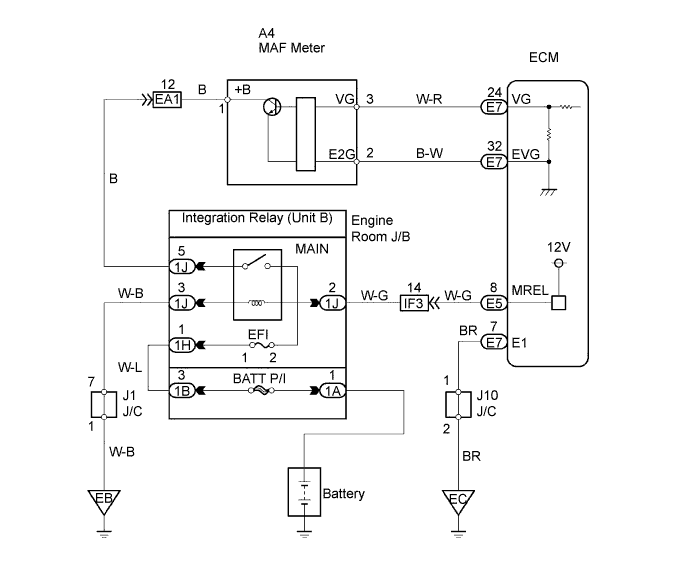

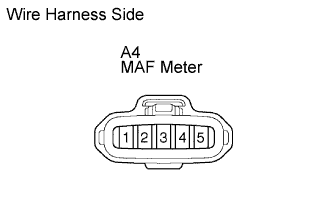

| 2.CHECK MASS AIR FLOW METER (POWER SOURCE) |

|

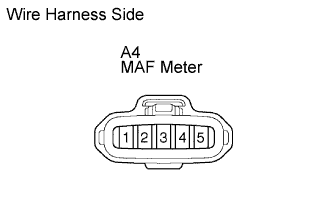

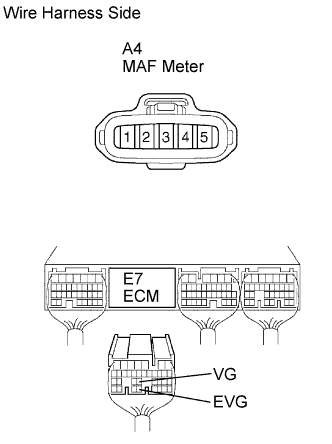

Disconnect the A4 MAF meter connector.

Turn the ignition switch ON.

Measure the voltage of the wire harness side connector.

| Tester Connection | Specified Condition |

| A4-1 - Body ground | 9 to 14 V |

|

| ||||

| OK | |

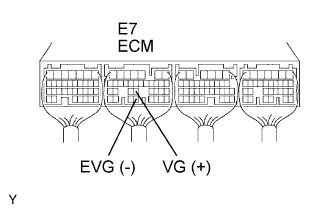

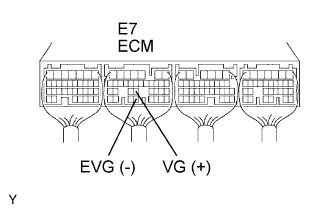

| 3.CHECK ECM (VG VOLTAGE) |

|

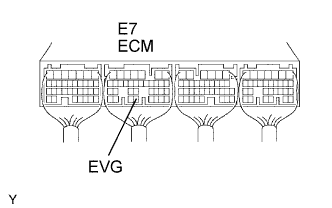

Start the engine.

Measure the voltage of the ECM connector.

| Tester Connection | Condition | Specified Condition |

| E7-24 (VG) - E7-32 (EVG) | Engine idling | 0.5 to 3.4 V |

|

| ||||

| NG | |

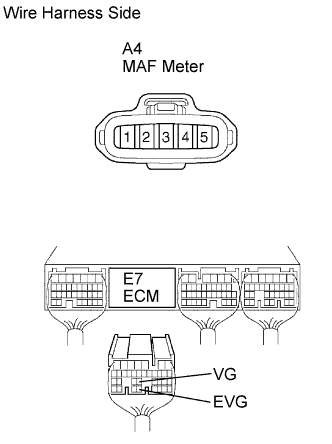

| 4.CHECK WIRE HARNESS (MASS AIR FLOW METER - ECM) |

|

Disconnect the A4 MAF meter connector.

Disconnect the E7 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| A4-3 - E7-24 (VG) | Below 1 Ω |

| A4-2 - E7-32 (EVG) | Below 1 Ω |

| A4-3 or E7-24 (VG) - Body ground | 10 kΩ or higher |

| A4-2 or E7-32 (EVG) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||

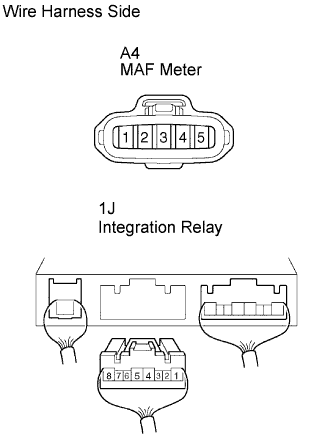

| 5.CHECK WIRE HARNESS (MASS AIR FLOW METER - MAIN RELAY) |

|

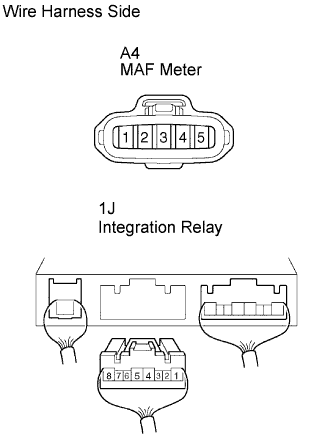

Disconnect the A4 MAF meter connector.

Remove the integration relay from the engine room J/B (Click here).

Disconnect the 1J integration relay connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| A4-1 - 1J-5 | Below 1 Ω |

| A4-1 or 1J-5 - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||

| 6.CHECK ECM (SENSOR GROUND) |

|

Measure the resistance of the ECM connector.

| Tester Connection | Specified Condition |

| E7-32 (EVG) - Body ground | Below 1 Ω |

|

| ||||

| OK | |

| 7.CHECK WIRE HARNESS (MASS AIR FLOW METER- ECM) |

|

Disconnect the A4 MAF meter connector.

Disconnect the E7 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| A4-3 - E7-24 (VG) | Below 1 Ω |

| A4-2 - E7-32 (EVG) | Below 1 Ω |

| A4-3 or E7-24 (VG) - Body ground | 10 kΩ or higher |

| A4-2 or E7-32 (EVG) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||

| 1.CHECK ECM (VG VOLTAGE) |

|

Start the engine.

Measure the voltage of the ECM connector.

| Tester Connection | Condition | Specified Condition |

| E7-24 (VG) - E7-32 (EVG) | Engine idling | 0.5 to 3.4 V |

|

| ||||

| NG | |

| 2.CHECK MASS AIR FLOW METER (POWER SOURCE) |

|

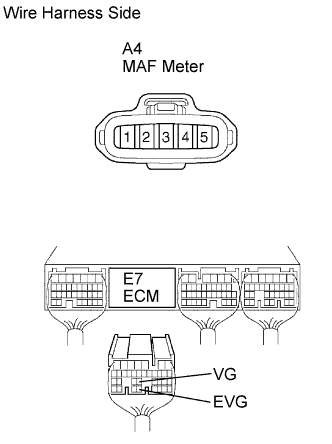

Disconnect the A4 MAF meter connector.

Turn the ignition switch ON.

Measure the voltage of the wire harness side connector.

| Tester Connection | Specified Condition |

| A4-1 - Body ground | 9 to 14 V |

|

| ||||

| OK | |

| 3.CHECK WIRE HARNESS (MASS AIR FLOW METER - ECM) |

|

Disconnect the A4 MAF meter connector.

Disconnect the E7 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| A4-3 - E7-24 (VG) | Below 1 Ω |

| A4-2 - E7-32 (EVG) | Below 1 Ω |

| A4-3 or E7-24 (VG) - Body ground | 10 kΩ or higher |

| A4-2 or E7-32 (EVG) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||

| 4.CHECK WIRE HARNESS (MASS AIR FLOW METER - MAIN RELAY) |

|

Disconnect the A4 MAF meter connector.

Remove the integration relay from the engine room J/B (Click here).

Disconnect the 1J integration relay connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| A4-1 - 1J-5 | Below 1 Ω |

| A4-1 or 1J-5 - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||