DTC P0100 Mass Air Flow Circuit Malfunction |

DTC P0102 Mass Air Flow Circuit Low |

DTC P0103 Mass Air Flow Circuit High |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0100 | Open or short in MAF meter circuit for 3 seconds |

|

| P0102 | Open in MAF meter circuit for 3 seconds |

|

| P0103 | Short in MAF meter circuit for 3 seconds |

|

| Mass Air Flow Rate (gm/s) | Malfunction |

| Approximately 0.0 |

|

| 271.0 or more |

|

| 1.READ DATA LIST (MASS AIR FLOW RATE) |

Connect the intelligent tester to the DLC3.

Start the engine.

Turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / MAF.

Read the value.

| Mass Air Flow Rate (g/s) | Proceed to |

| Approximately 0.0 | A |

| 271.0 or more | B |

| Between 1.0 and 270.0 * | C |

|

| ||||

|

| ||||

| A | |

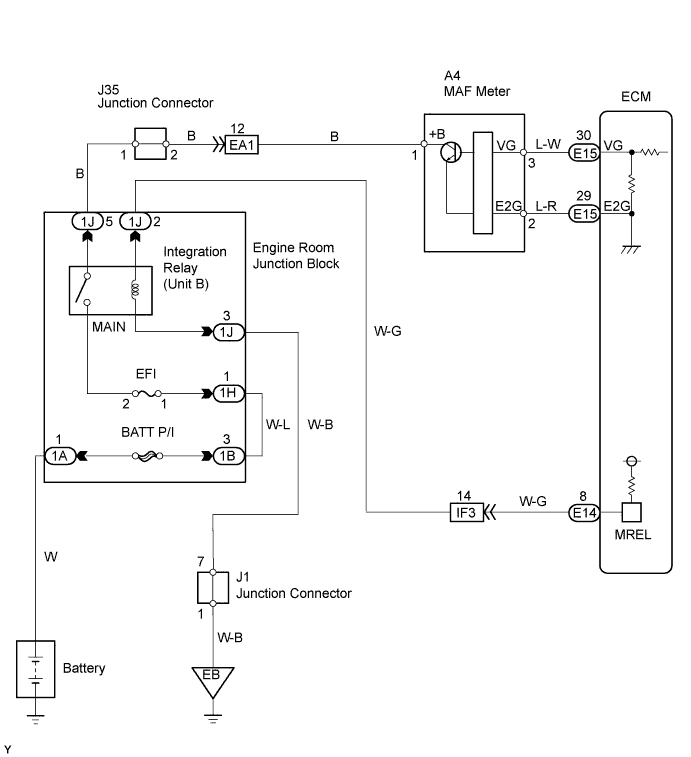

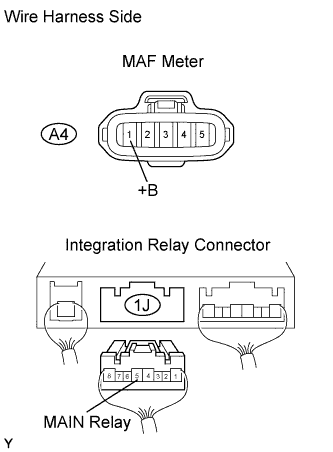

| 2.INSPECT MASS AIR FLOW METER (POWER SOURCE) |

|

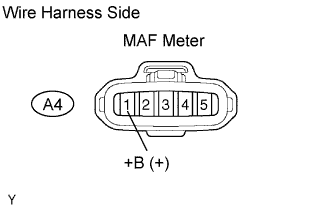

Disconnect the A4 MAF meter connector.

Turn the ignition switch ON.

Measure the voltage of the wire harness side connector.

| Tester Connection | Specified Condition |

| A4-1 (+B) - Body ground | 9 to 14 V |

|

| ||||

| OK | |

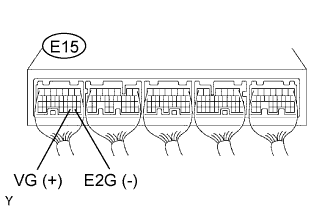

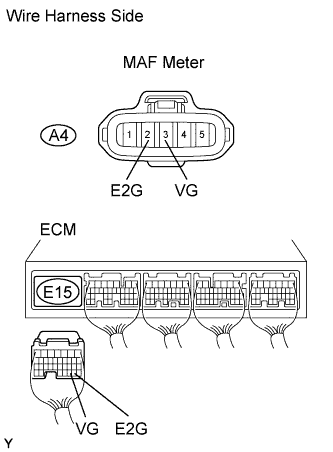

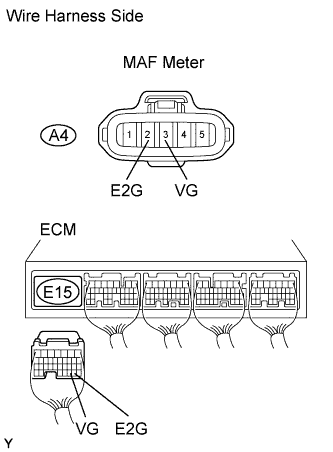

| 3.INSPECT ECM (VG VOLTAGE) |

|

Start the engine.

Measure the voltage of the ECM connector.

| Tester Connection | Condition | Specified Condition |

| E15-30 (VG) - E15-29 (E2G) | Engine is idling | 0.5 to 3.0 V |

|

| ||||

| NG | |

| 4.CHECK WIRE HARNESS (MASS AIR FLOW METER - ECM) |

|

Disconnect the A4 MAF meter connector.

Disconnect the E15 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| A4-3 (VG) - E15-30 (VG) | Below 1 Ω |

| A4-2 (E2G) - E15-29 (E2G) | Below 1 Ω |

| A4-3 (VG) or E15-30 (VG) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||

| 5.CHECK WIRE HARNESS (MASS AIR FLOW METER - INTEGRATION RELAY) |

|

Disconnect the A4 MAF meter connector.

Disconnect the 1J integration relay connector from the engine room junction block.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| A4-1 (+B) - 1J-5 | Below 1 Ω |

| A4-1 (+B) or 1J-5- Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||

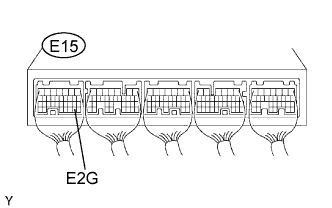

| 6.INSPECT ECM (SENSOR GROUND) |

|

Measure the resistance of the ECM connector.

| Tester Connection | Specified Condition |

| E15-29 (E2G) - Body ground | Below 1 Ω |

|

| ||||

| OK | |

| 7.CHECK WIRE HARNESS (MASS AIR FLOW METER - ECM) |

|

Disconnect the A4 MAF meter connector.

Disconnect the E15 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| A4-3 (VG) - E15-30 (VG) | Below 1 Ω |

| A4-2 (E2G) - E15-29 (E2G) | Below 1 Ω |

| A4-3 (VG) or E15-30 (VG) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||