DTC P0340 Camshaft Position Sensor Circuit Malfunction |

DTC P0342 Camshaft Position Sensor "A" Circuit Low Input (Bank 1 or Single Sensor) |

DTC P0343 Camshaft Position Sensor "A" Circuit High Input (Bank 1 or Single Sensor) |

DTC P0345 Camshaft Position Sensor "A" Circuit (Bank 2) |

DTC P0347 Camshaft Position Sensor "A" Circuit Low Input (Bank 2) |

DTC P0348 Camshaft Position Sensor "A" Circuit High Input (Bank 2) |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0340 P0345 | STA ON: No camshaft position sensor signal to ECM during cranking for 4 seconds or more STA OFF: No camshaft position sensor signal to ECM with engine speed 600 or more |

|

| P0342 P0347 | Output voltage of Variable Valve Timing (VVT) sensor 0.3 V or less for 5 seconds (1 trip detection logic) |

|

| P0343 P0348 | Output voltage of VVT sensor 4.7 V or more for 5 seconds (1 trip detection logic) |

|

| 1.CHECK ECM TERMINAL VOLTAGE |

|

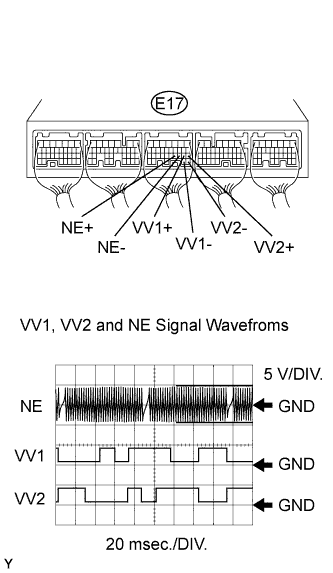

Inspect using an oscilloscope.

While the engine is idling, check the waveform of the ECM connector.

| Tester Connection | E17-19 (VV1+) - E17-29 (VV1-) E17-18 (VV2+) - E17-28 (VV2-) E17-21 (NE+) - E17-20 (NE-) |

| Tool Setting | 5 V/DIV., 20 msec./DIV. |

| Condition | Idling |

|

| ||||

| OK | |

| 2.CHECK WIRE HARNESS (SENSOR POWER SOURCE) |

|

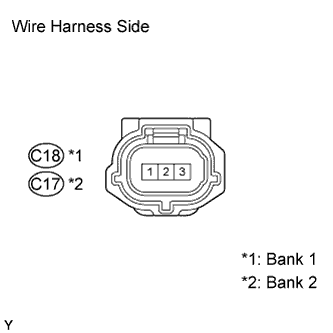

Disconnect the C17 or C18 VVT sensor connector.

Turn the ignition switch ON.

Measure the voltage of the wire harness side connector.

| Tester Connection | Specified Condition |

| C18-3 (VC) - Body ground | 4.5 to 5.5 V |

| C17-3 (VC) - Body ground | 4.5 to 5.5 V |

|

| ||||

| OK | |

| 3.CHECK WIRE HARNESS (VVT SENSOR - ECM) |

|

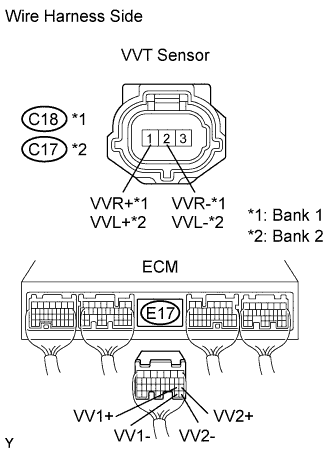

Disconnect the C17 and C18 VVT sensor connectors.

Disconnect the E17 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| C18-1 (VVR+) - E17-19 (VV1+) | Below 1 Ω |

| C17-1 (VVL+) - E17-18 (VV2+) | Below 1 Ω |

| C18-2 (VVR-) - E17-29 (VV1-) | Below 1 Ω |

| C17-2 (VVL-) - E17-28 (VV2-) | Below 1 Ω |

| C18-1 (VVR+) or E17-19 (VV1+) - Body ground | 10 kΩ or higher |

| C17-1 (VVL+) or E17-18 (VV2+) - Body ground | 10 kΩ or higher |

| C18-2 (VVR-) or E17-29 (VV1-) - Body ground | 10 kΩ or higher |

| C17-2 (VVL-) or E17-28 (VV2-) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 4.CHECK SENSOR INSTALLATION (VVT SENSOR) |

|

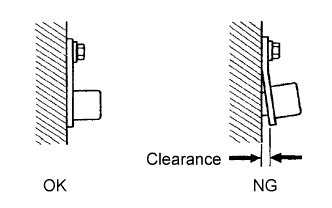

Check the VVT sensor installation.

|

| ||||

| OK | |

| 5.CHECK CAMSHAFT TIMING GEAR ASSEMBLY (TEETH OF PLATE) |

Check the teeth of the signal plate.

|

| ||||

| OK | ||

| ||