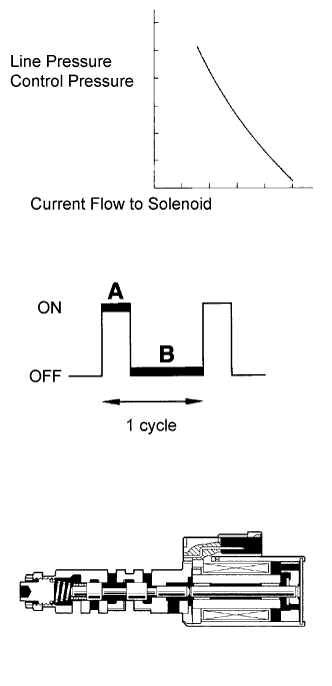

DTC P2714 Pressure Control Solenoid "D" Performance (Shift Solenoid Valve SLT) |

| DTC No. | DTC Detection Condition | Trouble Area |

| P2714 | ECM detects a malfunction on SLT (ON side) according to the revolution difference of the turbine and the output shaft, and also by the oil pressure (2 trip detection logic) |

|

| Item | Test Details | Diagnostic Note |

| Control the Line Pressure Up* | [Test Details] Operate shift solenoid SLT and raise line pressure [Vehicle Condition]

| - |

| 1.CHECK OTHER DTCS OUTPUT (IN ADDITION TO DTC P2714) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and push the intelligent tester main switch ON.

Enter the following menus: Powertrain / Engine and ECT / DTC / Current or Pending.

Read the DTCs using the intelligent tester.

| Display (DTC output) | Proceed to |

| Only P2714 is output | A |

| P2714 and other DTCs | B |

|

| ||||

| A | |

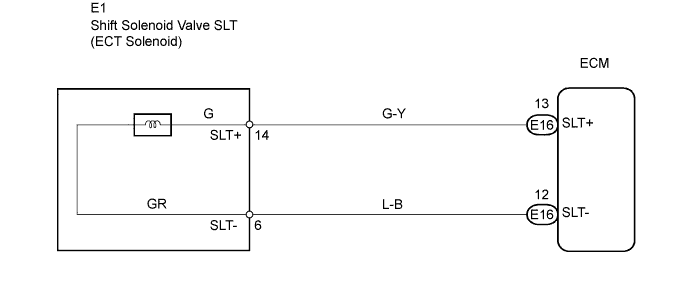

| 2.INSPECT SHIFT SOLENOID VALVE SLT |

|

Remove the shift solenoid valve SLT.

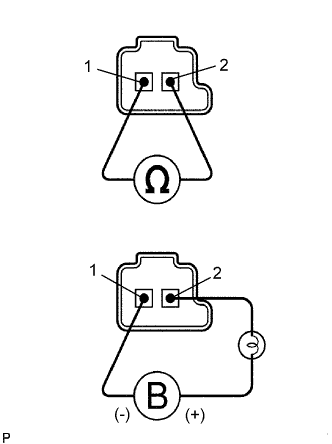

Measure the resistance of the solenoid valve.

Connect the battery's positive (+) lead to the terminal of the solenoid connector, and the negative (-) lead to the solenoid body.

|

| ||||

| OK | |

| 3.INSPECT TRANSMISSION VALVE BODY ASSEMBLY |

|

| ||||

| OK | |

| 4.INSPECT TORQUE CONVERTER CLUTCH ASSEMBLY |

|

| ||||

| OK | ||

| ||