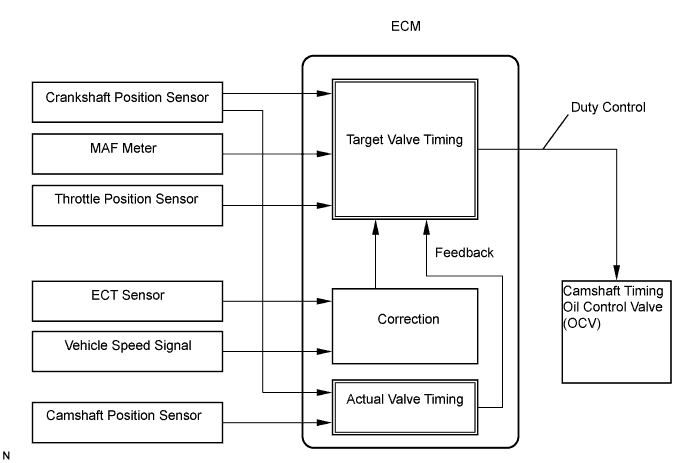

DTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1) |

DTC P0020 Camshaft Position "A" Actuator Circuit (Bank 2) |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0010 | Open or short in oil control valve circuit (bank 1) (1 trip detection logic) |

|

| P0020 | Open or short in oil control valve circuit (bank 2) (1 trip detection logic) |

|

| 1.PERFORM ACTIVE TEST (OPERATE OCV) |

Start and warm up the engine.

Turn the ignition switch OFF.

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the VVT System (bank 1) or Control the VVT System (bank 2).

Using the intelligent tester, operate the OCV and check the engine speed.

| Tester Operation | Specified Condition |

| OCV is OFF | Normal engine speed |

| OCV is ON | Roughly idle or engine stall |

|

| ||||

| NG | |

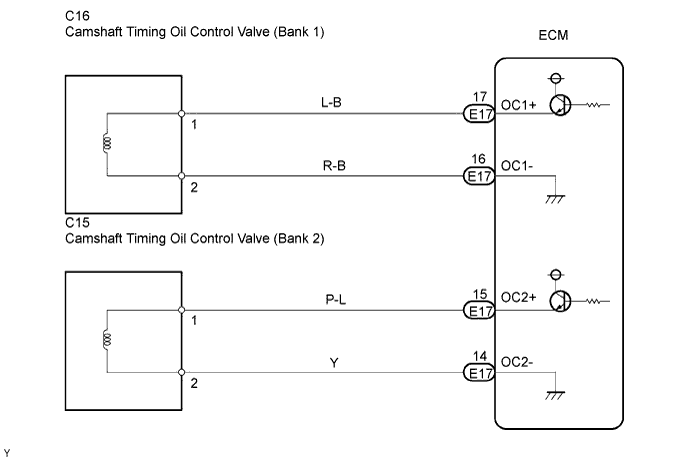

| 2.INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (OCV SIGNAL) |

|

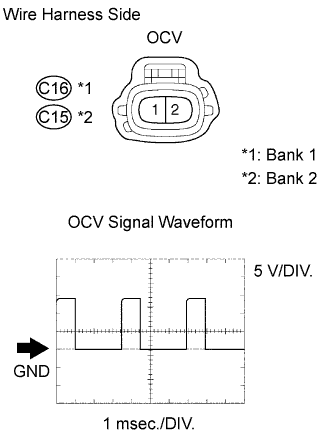

Disconnect the C15 or C16 OCV connectors.

While idling the engine, check the waveform of the OCV connectors using an oscilloscope.

| Tester Connection | C15-2 - C15-1 C16-2 - C16-1 |

| Tool Setting | 5 V/DIV., 1 msec./DIV. |

| Condition | Idling |

|

| ||||

| NG | |

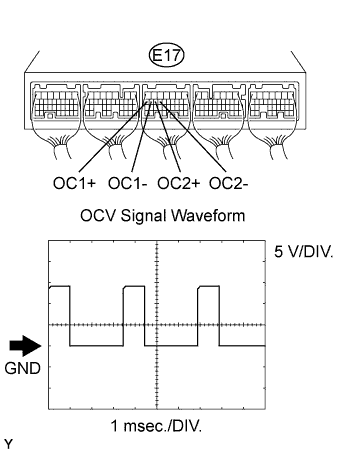

| 3.INSPECT ECM (OCV SIGNAL) |

|

While idling the engine, check the waveform of the ECM connector using an oscilloscope.

| Tester Connection | E17-17 (OC1+) - E17-16 (OC1-) E17-15 (OC2+) - E17-14 (OC2-) |

| Tool Setting | 5 V/DIV., 1 msec./DIV. |

| Condition | Idling |

|

| ||||

| NG | ||

| ||