ECD SYSTEM > Engine Difficult to Start or Stalling |

| 1.CHECK OUTPUT DTC (RELATED TO ENGINE) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / DTC.

Read DTCs.

| Display (DTC Output) | Proceed to |

| No output | A |

| DTCs related to engine (Click here) | B |

|

| ||||

| A | |

| 2.CHECK FUEL FILTER ASSEMBLY |

Check that the fuel filter is not clogged.

|

| ||||

| OK | |

| Go to step 2 |

| 3.CHECK ENGINE CRANKING CONDITION |

Check the engine cranking condition.

Compare the cranking condition with that of a normal engine of the same model, and carefully check if there is any difference between them.

|

| ||||

| OK | |

| 4.READ VALUE OF FUEL PRESSURE SENSOR |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / Data List / Fuel Press.

Read the values.

| Item | Inspection Condition | Reference Value |

| Fuel Press | Cranking, and engine coolant temperature 0°C (32°F) or more | 20 to 55 MPa |

|

| ||||

| OK | |

| 5.CHECK IF INITIAL COMBUSTION OCCURS |

Check if initial combustion occurs.

| Result | Proceed To |

| No initial combustion with cold engine | A |

| No initial combustion with hot engine | B |

| Initial combustion occurs | C |

|

| ||||

|

| ||||

| A | |

| 6.CHECK GLOW INDICATOR LIGHTING TIME AND AFTER GLOW TIME |

Check the lighting duration of glow indicator light (Click here).

|

| ||||

| OK | |

| 7.READ VALUE OF FUEL PRESSURE SENSOR |

Connect the intelligent tester to the DLC3.

Start the engine and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / Data List / Fuel Press.

Check that the internal fuel pressure of the common rail is within the specification below.

| Engine Speed | Fuel Pressure |

| Idling | Approximately 25 to 35 MPa |

| 3,000 rpm (No engine load) | Approximately 35 to 55 MPa |

|

| ||||

| OK | |

| 8.CHECK AIR INTAKE SYSTEM AND EXHAUST SYSTEM |

Remove the air cleaner filter.

Inspect the throttle valve operation.

Start the engine.

Check if the throttle valve fully opens when accelerating the engine speed.

|

| ||||

| OK | |

| 9.READ VALUE OF FUEL PRESSURE SENSOR AND INJECTOR |

Connect the intelligent tester to the DLC3.

Start the engine and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / Data List.

Select the following menu items in order and read the values.

| Item | Engine Speed* | Reference Value |

| Fuel Press | Idling | 25 to 35 MPa |

| Fuel Press | 2,000 rpm (No engine load) | 25 to 35 MPa |

| Fuel Press | 3,000 rpm (No engine load) | 35 to 45 MPa |

| Injection Volume | Idling | 3 to 10 mm3

|

| Injection Volume | 2,000 rpm (No engine load) | 3 to 10 mm3

|

| Injection Volume | 3,000 rpm (No engine load) | 4 to 12 mm3

|

|

| ||||

| OK | |

| 10.INSPECT CYLINDER COMPRESSION PRESSURE |

|

| ||||

| OK | |

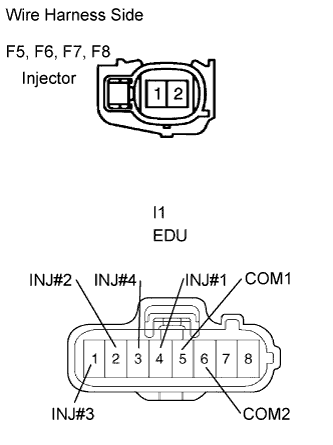

| 11.CHECK HARNESS AND CONNECTOR (INJECTOR - EDU) |

|

Disconnect the F5, F6, F7 and F8 injector connector.

Disconnect the I1 EDU connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition. |

| F5-1 - I1-4 (INJ#1) | Below 1 Ω |

| F6-1 - I1-2 (INJ#2) | Below 1 Ω |

| F7-1 - I1-1 (INJ#3) | Below 1 Ω |

| F8-1 - I1-3 (INJ#4) | Below 1 Ω |

| F5-2 - I1-5 (COM1) | Below 1 Ω |

| F6-2 - I1-6 (COM2) | Below 1 Ω |

| F7-2 - I1-6 (COM2) | Below 1 Ω |

| F8-2 - I1-5 (COM1) | Below 1 Ω |

| F5-1 or I1-4 (INJ#1) - Body ground | 10 kΩ or higher |

| F6-1 or I1-2 (INJ#2) - Body ground | 10 kΩ or higher |

| F7-1 or I1-1 (INJ#3) - Body ground | 10 kΩ or higher |

| F8-1 or I1-3 (INJ#4) - Body ground | 10 kΩ or higher |

| F5-2 or I1-5 (COM1) - Body ground | 10 kΩ or higher |

| F6-2 or I1-6 (COM2) - Body ground | 10 kΩ or higher |

| F7-2 or I1-6 (COM2) - Body ground | 10 kΩ or higher |

| F8-2 or I1-5 (COM1) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 12.PERFORM ACTIVE TEST BY INTELLIGENT TESTER (CONTROL CYLINDER FUEL CUT) |

Connect the intelligent tester to the DLC3.

Start the engine and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / Active Test / Control the Cylinder#1, #2, #3 and #4 Fuel Cut.

Check the engine idling condition while the fuel injection of each cylinder is cut using the intelligent tester.

| Engine Idling Condition | Proceed to |

| Becomes unstable | A |

| Does not change | B |

|

| ||||

| A | ||

| ||

| 13.CHECK IF FUEL IS BEING SUPPLIED TO SUPPLY PUMP |

Disconnect the inlet hose from the supply pump.

Operate the priming pump and check that the fuel is being supplied to the supply pump.

|

| ||||

| NG | ||

| ||

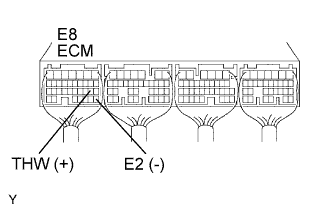

| 14.CHECK ECM TERMINAL VOLTAGE (THW TERMINAL) |

|

Start the engine.

Measure the voltage of the ECM connector.

| Tester Connection | Condition | Specified Condition |

| E8-19 (THW) - E8-28 (E2) | Idling, engine coolant temperature between 60 and 120°C (140 and 248°F) | 0.2 to 1.0 V |

|

| ||||

| OK | |

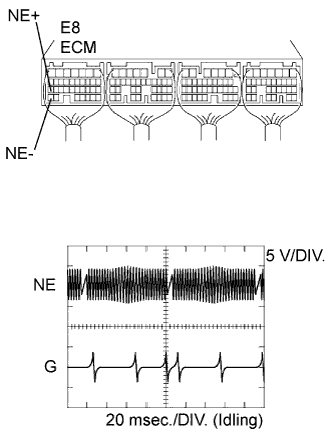

| 15.CHECK ECM TERMINAL VOLTAGE (NE+ AND NE- TERMINALS) |

|

While idling the engine, check the waveform between the specified terminals of the E7 ECM connector using an oscilloscope.

| Tester Connection | Specified Condition |

| E8-27 (NE+) - E8-34 (NE-) | Correct waveform is shown |

| Tool Setting | Condition |

| 5 V/DIV., 20 msec./DIV. | Idling with warm engine |

|

| ||||

| OK | |

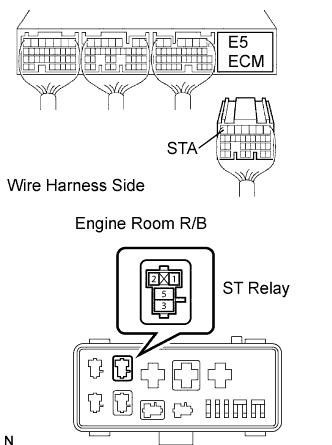

| 16.CHECK HARNESS AND CONNECTOR (STARTER RELAY - ECM) |

|

Disconnect the E5 ECM connector.

Remove the ST relay from the engine room R/B.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| R/B ST relay terminal 1 - E4-7 (STA) | Below 1 Ω |

| R/B ST relay terminal 1 or E4-7 (STA) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

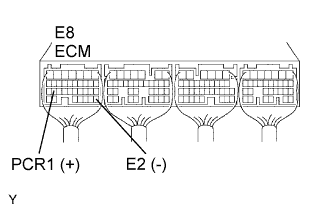

| 17.CHECK ECM TERMINAL VOLTAGE (PCR1 TERMINAL) |

|

Start the engine.

Measure the voltage of the ECM connector.

| Tester Connection | Condition | Specified Condition |

| E8-26 (PCR1) - E8-28 (E2) | Idling | 1.8 to 2.1 V |

|

| ||||

| OK | ||

| ||

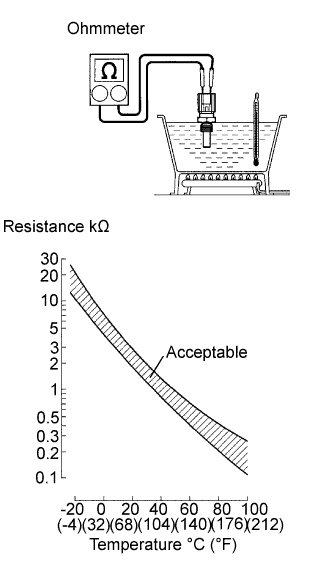

| 18.INSPECT ENGINE COOLANT TEMPERATURE SENSOR |

|

Remove the sensor.

Measure the resistance of the sensor

| Connection | Specified Condition |

| 20°C (68°F) | 2 2.32 to 2.59 kΩ |

| 80°C (176°F) | 0.310 to 0.326 kΩ |

|

| ||||

| OK | ||

| ||

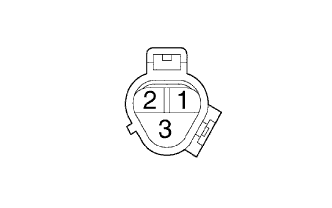

| 19.INSPECT CRANKSHAFT POSITION SENSOR |

|

Disconnect the C4 sensor connector.

Measure the resistance between terminals 1 and 2.

| Tester Connection | Condition | Specified Condition |

| 1 - 2 | Cold | 1,630 to 2,740 Ω |

| 1 - 2 | Hot | 2,065 to 3,225 Ω |

|

| ||||

| OK | ||

| ||

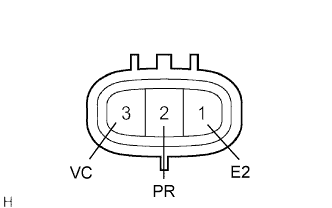

| 20.INSPECT COMMON RAIL ASSEMBLY (FUEL PRESSURE SENSOR) |

|

Disconnect the F9 sensor connector.

Measure the resistance of the sensor.

| Tester Connection | Specified Condition |

| F8-2 (PC) - F8-1 (E2) | 3 kΩ or less |

| F8-2 (PC) - F8-3 (VC) | 16.4 kΩ or less |

|

| ||||

| OK | |

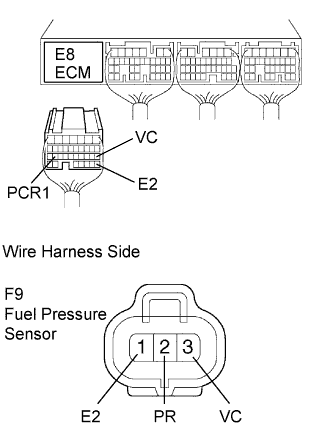

| 21.CHECK HARNESS AND CONNECTOR (FUEL PRESSURE SENSOR - ECM) |

|

Disconnect the E8 ECM connector.

Disconnect the F9 sensor connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| E8-26 (PCR1) - F9-2 (PR) | Below 1 Ω |

| E8-18 (VC) - F9-3 (VC) | Below 1 Ω |

| E8-28 (E2) - F9-1 (E2) | Below 1 Ω |

| E8-26 (PCR1) or F9-2 (PR) - Body ground | 10 kΩ or higher |

| E8-18 (VC) or F9-3 (VC) - Body ground | 10 kΩ or higher |

| E8-28 (E2) or F9-1 (E2) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

| 22.REPLACE ECM |

|

| ||||

| OK | ||

| ||