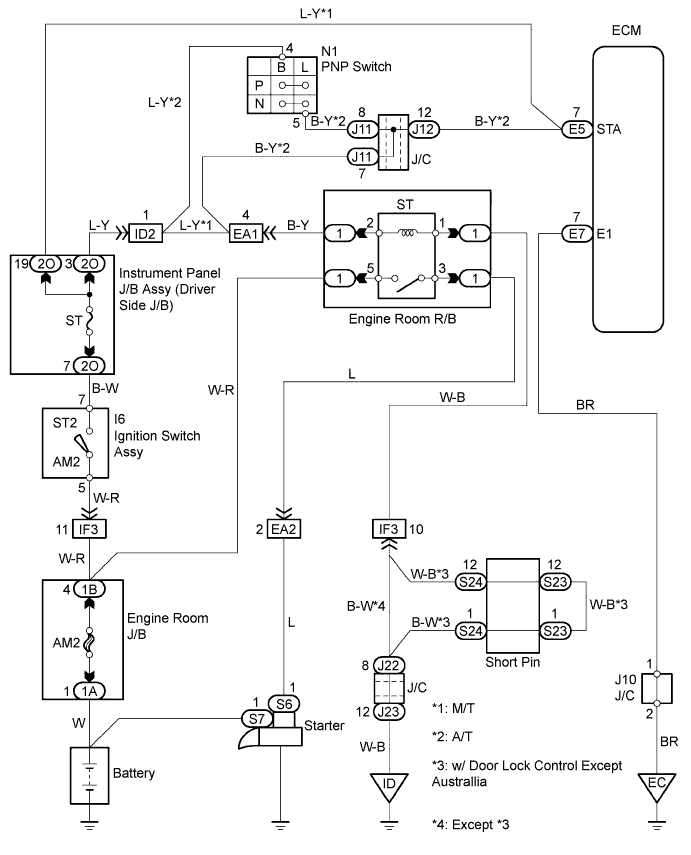

ECD SYSTEM > Starter Signal Circuit |

| 1.READ VALUE OF STARTER SIGNAL |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / Data List / Starter Signal.

Read the values.

| Ignition Switch Position | Starter SIG |

| ON | OFF |

| START | ON |

|

| ||||

| NG | |

| 2.CHECK WIRE HARNESS (ECM - ST RELAY) |

|

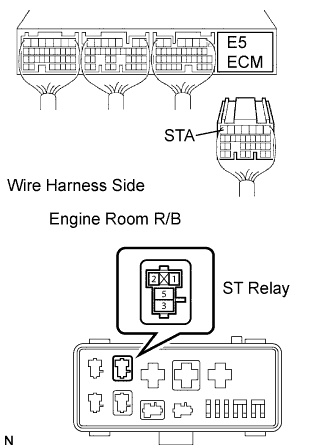

Disconnect the E5 ECM connector.

A/T:

Remove the ST relay from the engine room J/B.

M/T:

Disconnect the 2O J/B connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| R/B ST relay terminal 2 - E5-7 (STA) | Below 1 Ω |

| R/B ST relay terminal 2 or E5-7 (STA) - Body ground | 10 kΩ or higher |

| Tester Connection | Specified Condition |

| 2O-19 - E5-7 (STA) | Below 1 Ω |

| 2O-19 - E5-7 (STA) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||