DTC P0335 Crankshaft Position Sensor "A" Circuit |

DTC P0339 Crankshaft Position Sensor "A" Circuit Intermittent |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0335 | When one of the following conditions is met:

|

|

| P0339 | Conditions (a), (b) and (c) are met when no crankshaft position sensor signal is input for 0.05 sec. or more. (a) Engine revolution 1,000 rpm or more (b) STA signal is OFF (c) 3 sec. or more have lapsed after STA signal is switched from ON to OFF |

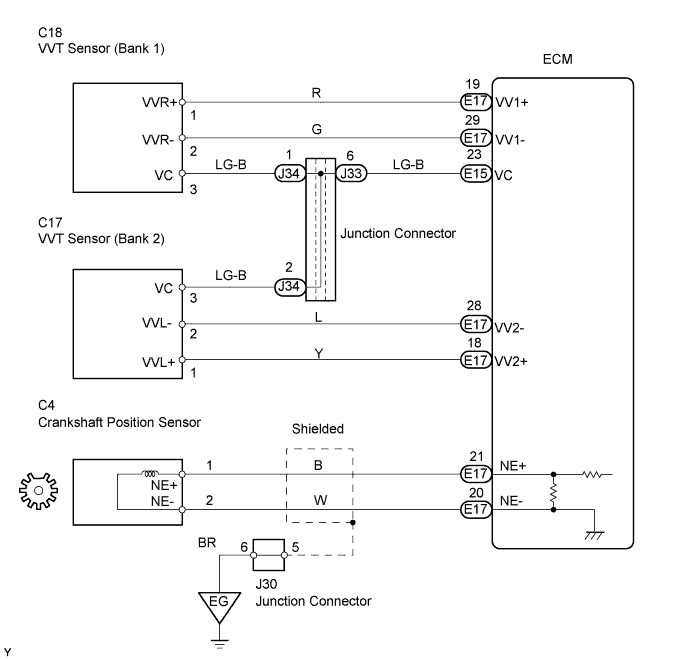

| Item | Contact |

| Symbols (Terminal No.) | NE+ (E17-21) - NE- (E17-20) VV1+ (E17-19) - VV1- (E17-29) VV2+ (E17-18) - VV2- (E17-28) |

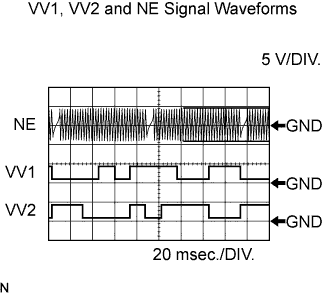

| Tool Setting | 5 V/DIV., 20 msec./DIV. |

| Condition | Idling |

| 1.INSPECT CRANKSHAFT POSITION SENSOR (RESISTANCE) |

|

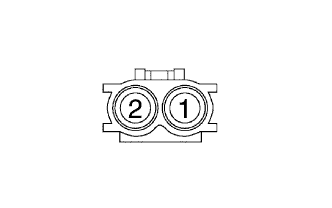

Disconnect the crankshaft position sensor connector.

Measure the resistance of the sensor.

| Tester Connection | Specified Condition |

| 1 - 2 | 1,630 to 2,740 Ω at cold |

| 1 - 2 | 2,065 to 3,225 Ω at hot |

|

| ||||

| OK | |

| 2.CHECK WIRE HARNESS (CRANKSHAFT POSITION SENSOR - ECM) |

|

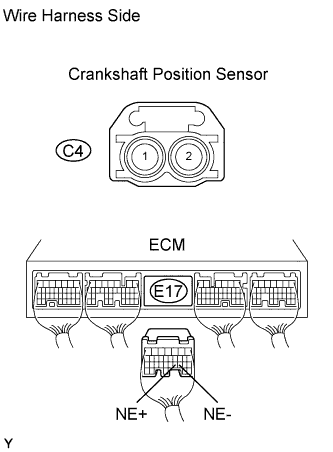

Disconnect the C4 crankshaft position sensor connector.

Disconnect the E17 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| C4-1 (NE+) - E17-21 (NE+) | Below 1 Ω |

| C4-2 (NE-) - E17-20 (NE-) | Below 1 Ω |

| C4-1 (NE+) - E17-21 (NE+) - Body ground | 10 kΩ or higher |

| C4-2 (NE-) - E17-20 (NE-) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | |

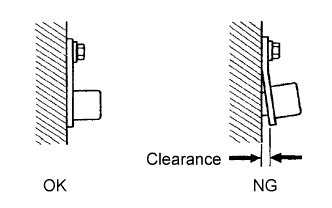

| 3.CHECK SENSOR INSTALLATION (CRANKSHAFT POSITION SENSOR) |

|

Check the crankshaft position sensor installation.

|

| ||||

| OK | |

| 4.CHECK CRANKSHAFT POSITION SENSOR PLATE (TEETH OF SENSOR PLATE) |

Check the teeth of the sensor plate.

|

| ||||

| OK | ||

| ||