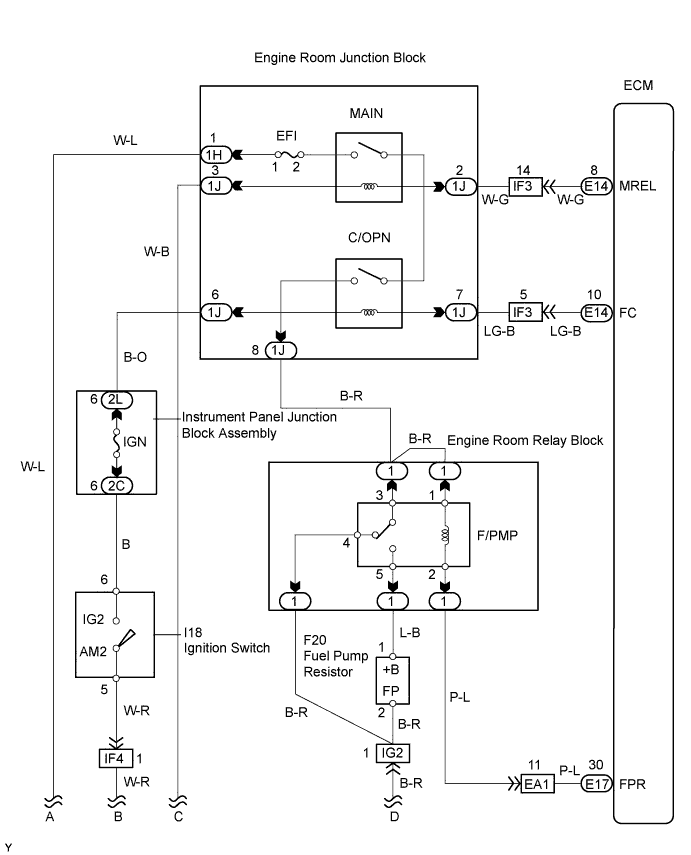

DTC P0230 Fuel Pump Primary Circuit |

| DTC No. | DTC Detection Condition | Trouble Area |

| P0230 | Open or short in F/PMP relay circuit for 0.5 second or more (1 trip detection logic) |

|

| 1.INSPECT ECM (FPR VOLTAGE) |

|

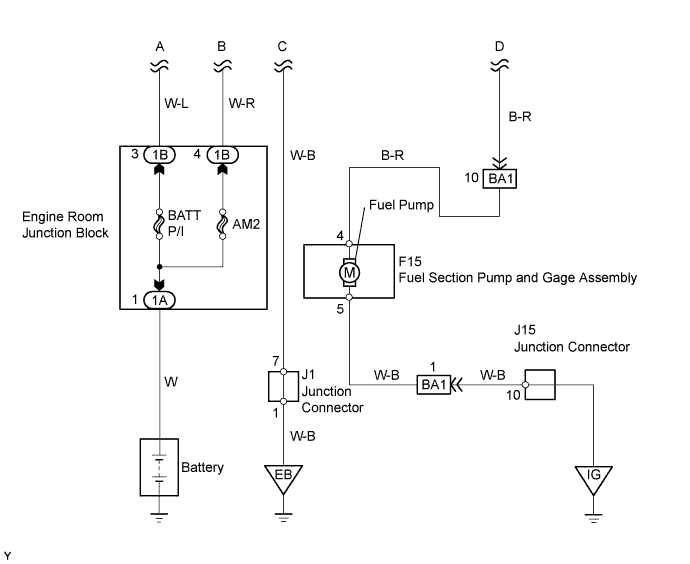

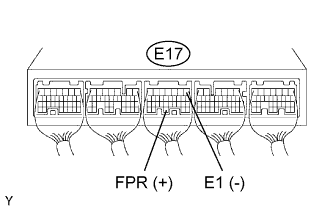

Measure the voltage of the ECM connectors.

| Tester Connection | Condition | Specified Condition |

| E17-30 (FPR) - E17-1 (E1) | STA signal ON | 9 to 14 V |

| E17-30 (FPR) - E17-1 (E1) | STA signal OFF | 0 to 3 V |

|

| ||||

| OK | |

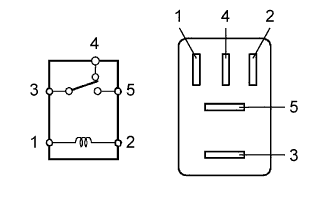

| 2.INSPECT RELAY (Marking: F/PMP) |

|

Remove the F/PMP relay from the engine room relay block.

Measure the resistance the relay.

| Tester Connection | Specified Condition |

| 3 - 4 | Below 1 Ω |

| 3 - 5 | 10 kΩ or higher |

| 3 - 4 | 10 kΩ or higher (when battery voltage applied to terminals 1 and 2) |

| 3 - 5 | Below 1 Ω (when battery voltage applied to terminals 1 and 2) |

|

| ||||

| OK | |

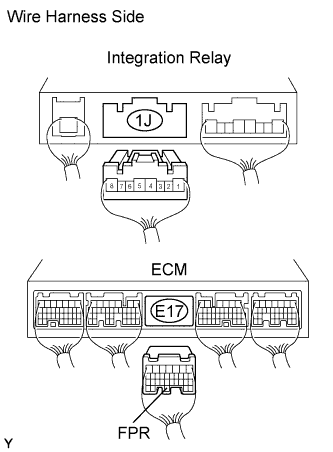

| 3.CHECK WIRE HARNESS (F/PMP RELAY - ECM) |

|

Remove the F/PMP relay from the engine room relay block.

Disconnect the E17 ECM connector.

Measure the resistance of the wire harness side connectors.

| Tester Connection | Specified Condition |

| F/PMP relay (2) - E17-30 (FPR) | Below 1 Ω |

| F/PMP relay (2) or E17-30 (FPR) - Body ground | 10 kΩ or higher |

|

| ||||

| OK | ||

| ||